A big thank you @m.blt for all the help you gave me.

Here is my final code (mostly yours @m.blt ), if it can be useful to anyone:

Option Explicit

Dim nbTotalCorps As Integer

Dim nbTotalDossier As Integer

Dim nbModifCorps As Integer

Dim nbModifDossier As Integer

Dim pieceCorps As Boolean

Dim swApp As SldWorks.SldWorks

Dim boolstatus As Boolean

Dim swCustBend2 As CustomBendAllowance

Dim swSheetMetal As SldWorks.SheetMetalFeatureData

Sub main()

Dim swModel As ModelDoc2

Dim swAssemb As AssemblyDoc

Dim swComp As Component2

Dim vComponents As Variant

Dim i As Integer

Dim OK As Boolean

nbTotalCorps = 0

nbTotalDossier = 0

nbModifCorps = 0

nbModifDossier = 0

Set swApp = Application.SldWorks

Set swModel = swApp.ActiveDoc

If swModel Is Nothing Then ' Si aucun document n'est ouvert

MsgBox "Un document de pièce ou d'assemblage doit être ouvert.", vbExclamation

Exit Sub

ElseIf swModel.GetType = swDocPART Then ' Si c'est une pièce...

OK = SheetPart(Nothing, swModel)

MsgBox nbModifDossier & " rayon de pliage modifier sur " & nbTotalDossier & " de dossier par défaut de tolerie" & vbCrLf & _

nbModifCorps & " rayon de pliage modifier sur " & nbTotalCorps & " corps de tolerie"

Exit Sub

ElseIf swModel.GetType = swDocASSEMBLY Then ' Si c'est un assemblage...

Set swAssemb = swModel

vComponents = swAssemb.GetComponents(True) ' Tableau des composants de niveau 1 de l'assemblage

For i = 0 To UBound(vComponents)

Set swComp = vComponents(i)

ParcourirComposants swComp ' Parcours des composants (récursif)

Next i

MsgBox nbModifDossier & " rayon de pliage modifier sur " & nbTotalDossier & " de dossier par défaut de tolerie" & vbCrLf & _

nbModifCorps & " rayon de pliage modifier sur " & nbTotalCorps & " corps de tolerie"

End If

swModel.ForceRebuild3 (True)

End Sub

Sub ParcourirComposants(swComp As SldWorks.Component2)

Dim vChildComponents As Variant

Dim swModel As ModelDoc2

Dim swChildComp As SldWorks.Component2

Dim i As Integer

Dim OK As Boolean

Set swModel = swComp.GetModelDoc2 ' Modèle associé au composant

If Not swModel Is Nothing Then

If swModel.GetType = swDocPART Then ' Si c'est une pièce...

OK = SheetPart(swComp, swModel)

ElseIf swModel.GetType = swDocASSEMBLY Then ' Si c'est un assemblage...

vChildComponents = swComp.GetChildren ' Liste des composants enfants

For i = 0 To UBound(vChildComponents)

Set swChildComp = vChildComponents(i)

ParcourirComposants swChildComp ' Parcours du composant enfant (récursif)

Next i

End If

End If

End Sub

Function SheetPart(swComp As Component2, swModel As ModelDoc2) As Boolean

Dim swFeat As Feature

Dim vFeatArray As Variant

Dim sheetMetalFolder As sheetMetalFolder

Dim swSelMgr As SelectionMgr

Dim swSheetMetalData As SheetMetalFeatureData

Dim swCustBend As CustomBendAllowance

Dim gaugeTableFile As String

Dim i As Long

Dim bRet As Boolean

Dim lRet As Long

Dim errors As Long

Dim overrideParameters As Boolean

Dim swFeature As SldWorks.Feature

Set sheetMetalFolder = swModel.FeatureManager.GetSheetMetalFolder

If sheetMetalFolder Is Nothing Then

Exit Function

End If

Set swFeat = sheetMetalFolder.GetFeature

Debug.Print "-------------------------------------------------"

Debug.Print "Composant : " & swModel.GetPathName

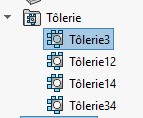

Debug.Print " Nom du dossier de tôlerie : " & swFeat.Name

Debug.Print " Nombre de fonctions de tôlerie dans le dossier : " & sheetMetalFolder.GetSheetMetalCount

Debug.Print ""

'Création du tableau comportant chaque element de tolerie contenu dans le dossier de tolerie

vFeatArray = sheetMetalFolder.GetSheetMetals

'Stop

Debug.Print " Nom du dossier de tôlerie : " & vFeatArray(0).Name

'

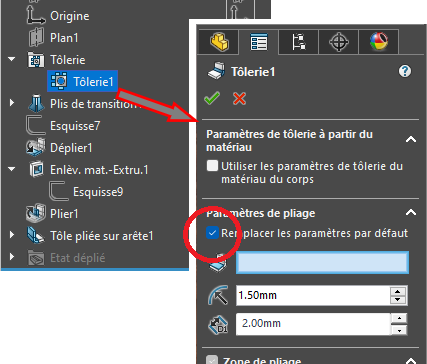

Set swSheetMetalData = swFeat.GetDefinition

Set swCustBend = swSheetMetalData.GetCustomBendAllowance

'Accession au parametres de tolerie par défaut

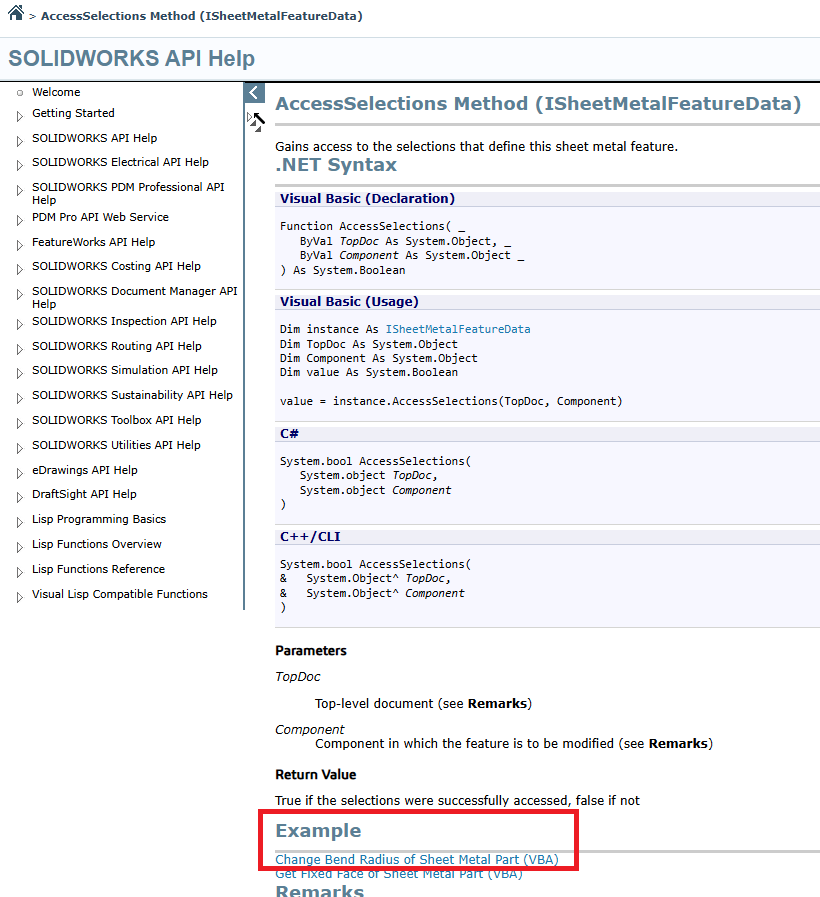

If swApp.ActiveDoc.GetType = swDocPART Then ' Si document principal type PIECE

bRet = swSheetMetalData.AccessSelections(swModel, Nothing)

Else

bRet = swSheetMetalData.AccessSelections(swApp.ActiveDoc, swComp) ' ou si type ASSEMBLAGE

End If

pieceCorps = True

nbTotalDossier = nbTotalDossier + 1

'Appel de la fonction choixRayonPliageParEpaisseur

choixRayonPliageParEpaisseur swCustBend, swSheetMetalData, swComp, swModel, swFeat

Debug.Print " Modified bend radius = " & swSheetMetalData.BendRadius * 1000# & " mm"

'Boucle sur les elements de tolerie contenu dans le dossier

For i = LBound(vFeatArray) To UBound(vFeatArray)

Set swFeat = vFeatArray(i)

Set swSheetMetalData = swFeat.GetDefinition

Set swCustBend = swSheetMetalData.GetCustomBendAllowance

pieceCorps = False

nbTotalCorps = nbTotalCorps + 1

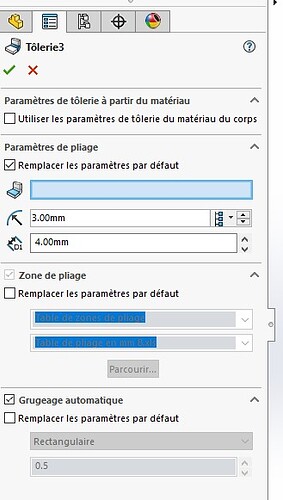

'verification de l'état "Remplacer les parametres de pliage"

errors = swSheetMetalData.GetOverrideDefaultParameter2(swSheetMetalOverrideDefaultParameters_BendParameters, overrideParameters)

Debug.Print (" Bend parameters: " & overrideParameters)

'Si "remplacer les parametres de pliage" est coché

If overrideParameters Then

'On accede au parametres de pliage et à la zone de pliage

errors = swSheetMetalData.SetOverrideDefaultParameter2(swSheetMetalOverrideDefaultParameters_BendParameters, True)

errors = swSheetMetalData.SetOverrideDefaultParameter2(swSheetMetalOverrideDefaultParameters_BendAllowance, True)

'Appel de la fonction choixRayonPliageParEpaisseur

choixRayonPliageParEpaisseur swCustBend, swSheetMetalData, swComp, swModel, swFeat

Debug.Print " Modified bend radius = " & swSheetMetalData.BendRadius * 1000# & " mm"

End If

Debug.Print " " & swFeat.Name

Debug.Print " Tolérance de pliage = " & swSheetMetalData.BendAllowance * 1000# & " mm"

Debug.Print " Fichier de table de pliage = " & swSheetMetalData.bendTablefile

Debug.Print " Epaisseur = " & swSheetMetalData.Thickness * 1000# & " mm"

Debug.Print " Rayon = " & swSheetMetalData.BendRadius * 1000# & " mm"

Debug.Print " Perte au pli = " & swCustBend.BendDeduction * 1000# & " mm"

Debug.Print " KFactor = " & swSheetMetalData.KFactor

Debug.Print " Type de pli = " & swCustBend.Type

Debug.Print ""

Next i

End Function

Sub choixRayonPliageParEpaisseur(swCustBend As CustomBendAllowance, swSheetMetalData As SheetMetalFeatureData, _

swComp As Component2, swModel As ModelDoc2, swFeat As Feature)

'Stop

Dim bRet As Boolean

Dim epaisseur As Double

Dim rayon As Double

Dim tabEpRayon(4, 1) As Double

Dim j As Integer

Dim bendTablefile As String

tabEpRayon(0, 0) = 1.5

tabEpRayon(0, 1) = 1.5

tabEpRayon(1, 0) = 2

tabEpRayon(1, 1) = 2

tabEpRayon(2, 0) = 3

tabEpRayon(2, 1) = 3

tabEpRayon(3, 0) = 4

tabEpRayon(3, 1) = 4

tabEpRayon(4, 0) = 5

tabEpRayon(4, 1) = 5

bendTablefile = "C:\Program Files\SOLIDWORKS Corp 2022\SOLIDWORKS\lang\french\Sheetmetal Bend Tables\TABLE DE PLIAGE EN MM B.XLS"

epaisseur = swSheetMetalData.Thickness * 1000

rayon = swSheetMetalData.BendRadius * 1000

For j = 0 To 4

'Test si epaisseur 1.5mm, rayon de pliage 1.025 et utilisation d'une table de pliage

If tabEpRayon(j, 0) = epaisseur And tabEpRayon(j, 1) <> rayon Or _

tabEpRayon(j, 0) = epaisseur And swCustBend.Type <> 1 Or _

tabEpRayon(j, 0) = epaisseur And swSheetMetalData.bendTablefile <> bendTablefile Then

'Stop

swSheetMetalData.BendRadius = tabEpRayon(j, 1) / 1000

swCustBend.Type = 1

swSheetMetalData.bendTablefile = bendTablefile

If pieceCorps Then

nbModifDossier = nbModifDossier + 1

Else

nbModifCorps = nbModifCorps + 1

End If

End If

Next j

Debug.Print swModel.GetType

Debug.Print swModel.GetTitle

Debug.Print swComp.GetPathName

'On valide les modifications des parametres de tolerie

If swApp.ActiveDoc.GetType = swDocPART Then ' Si document principal type PIECE

bRet = swFeat.ModifyDefinition(swSheetMetalData, swModel, Nothing)

'Stop

Else

bRet = swFeat.ModifyDefinition(swSheetMetalData, swApp.ActiveDoc, swComp) ' ou si type ASSEMBLAGE

'Stop

End If

End Sub