Thanks for the tip @sbadenis ,

It's a shame that it still has to be done in 2 steps and that it doesn't exist when the rating is created.

Yes indeed I could have used the relative view function.

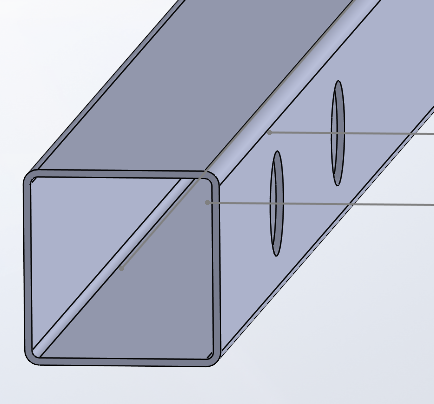

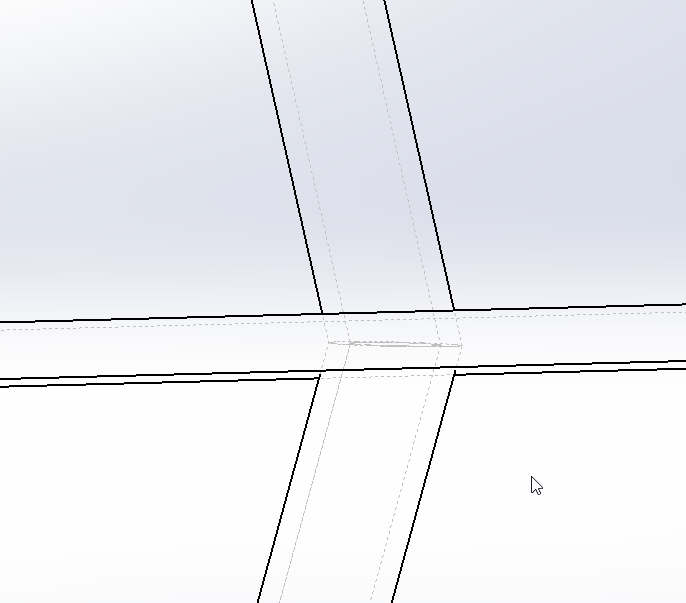

On the first photo, it's my complete plan and on the second, I insulate my tube in order to do all the preparation before assembly for welding.

I made the part in welded construction and I want the tubes to fit into the other one but when the part is insulated, the holes are not there because I didn't make any holes.

Is it possible to show holes that have not been made?

Hoping to have been a little clearer.

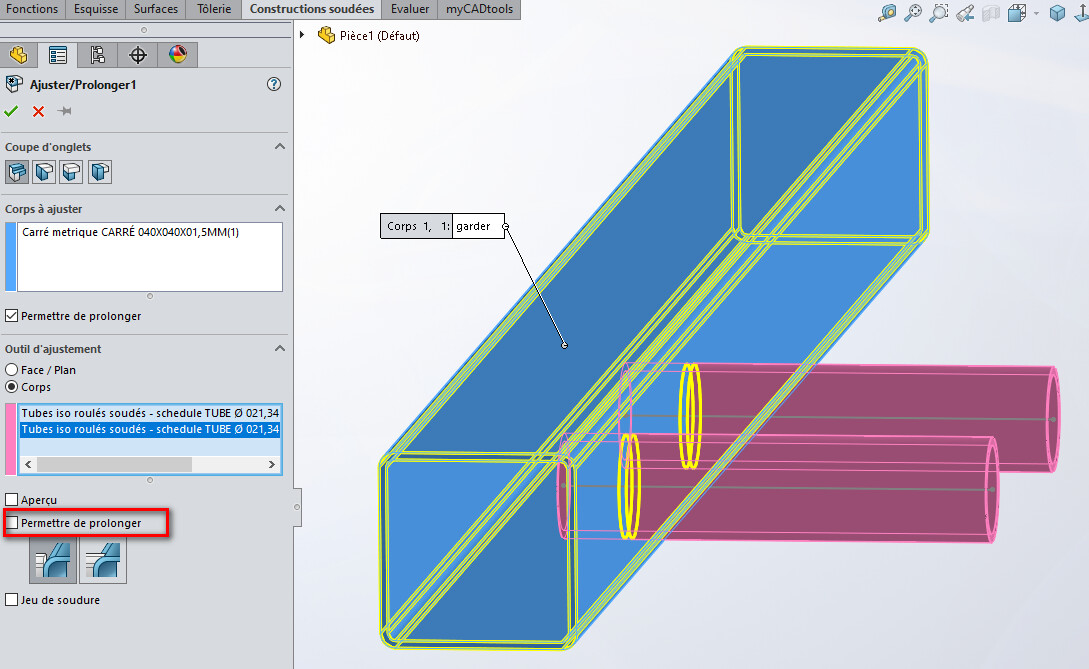

Well, make the holes... with the " Adjust/Extend " function of the Mechanically Welded tab:

https://help.solidworks.com/2022/french/Solidworks/sldworks/HIDD_DVE_FEAT_WELD_CORNER.htm?rid=145582

It doesn't work for me, I made the part from a sketch and then I placed my tubes in welded construction. I tried to extend the tube but the holes don't appear when the part is isolated on my plan...

Is it possible for you to transfer your mechanically welded part and its drawing to us (with the Solidworks version used)?

… Your sentence:

… intrigues me.

And it will be easier for us to identify the problems and define the solutions to be provided (if we find any).

Hello

Here is my file and you will find the bar that I have isolated on page 5 of the plan.

Thank you

The Solidworks version is missing (Presumably higher than 2022 since I can't open it)...

@Maclane

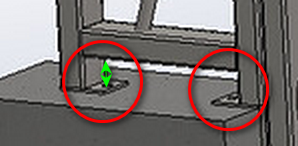

![]()

I would even say the education version, given the message when opening the file.

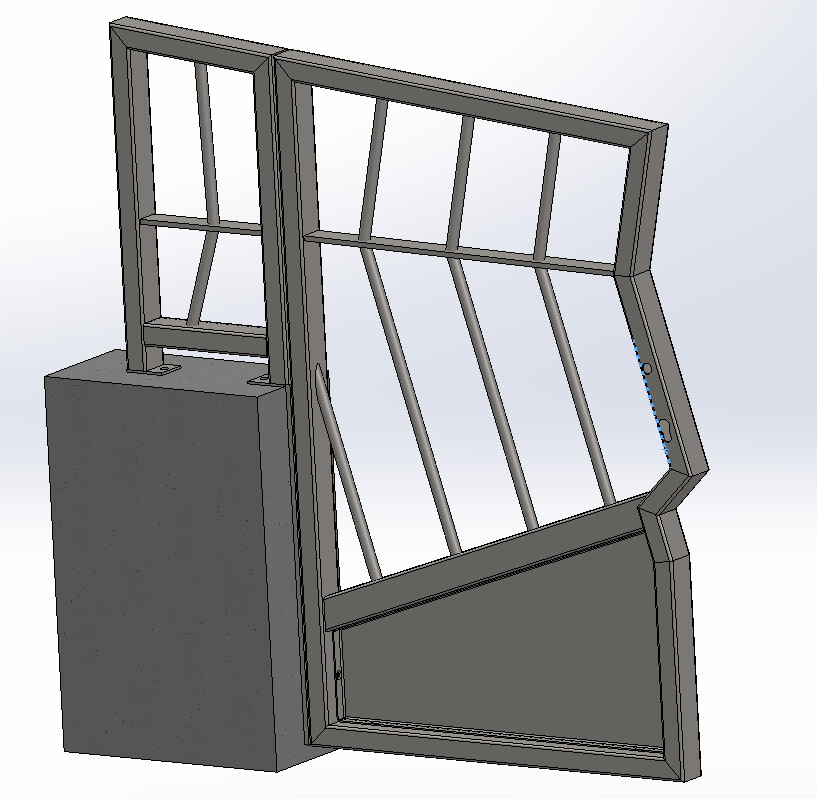

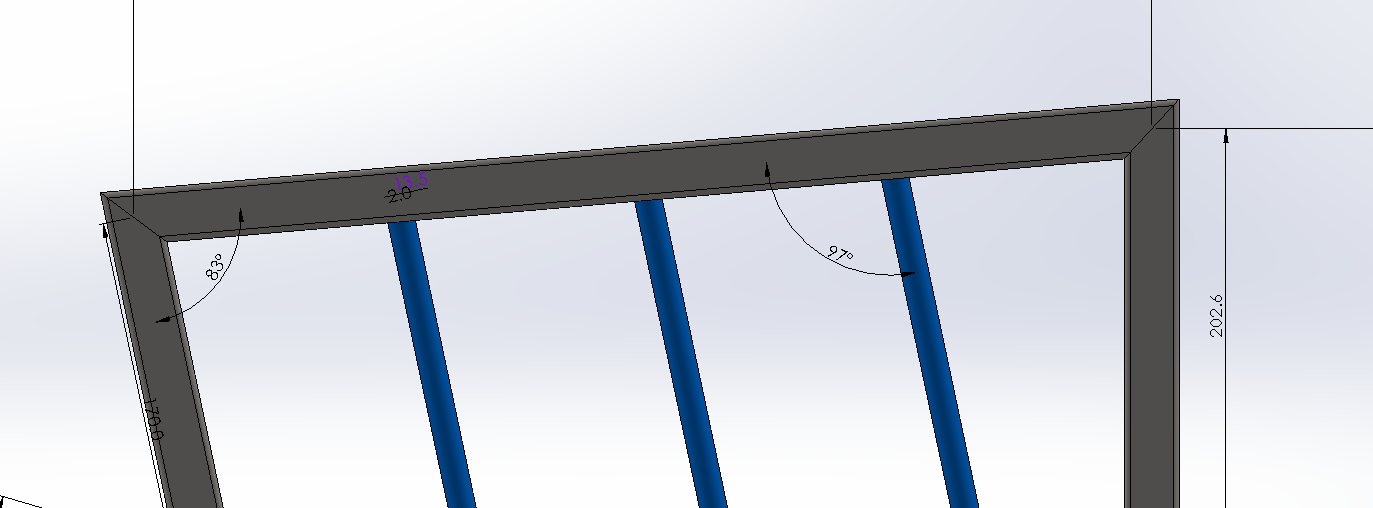

Otherwise @tonyguena , a little twisted your gate, right? ![]()

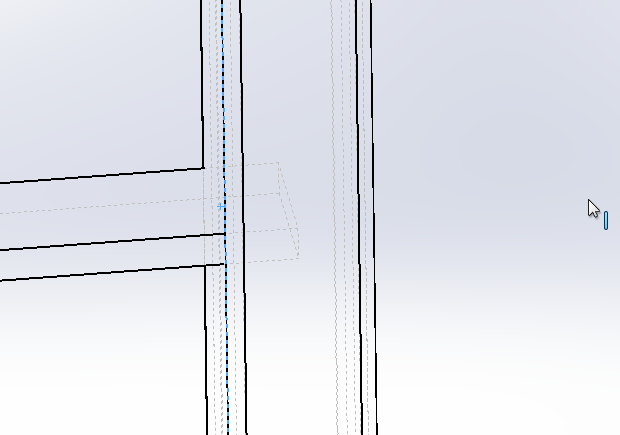

For the fit, simply choose the body to be adjusted, then the face of the tube for the fit, example with a tube attached (under SW2023 Sp05).

Careful:

Many are fooled on this point... (and me too)...

Depending on the type of fastener chosen, there may not be enough space between the plate and the profile to pass: Either the bolts or the tools (drill, bolter, etc.)

Except laser tube you may have a hard time orienting your drill with the different drilling angles for the passage of the bar (here 97°)

Wouldn't it be easier to adjust the length of your bars to your square tube?

And do the peripheral welds of the bars on the square tube.

Same thing for the adjustment of the round tubes on the center cover:

Basically, review all the adjustments:

Otherwise when the fit is not done well because of a crooked construction like here!

You can do one or more material removals and choose the bodies through which the removal will take place:

Hello, thank you for the answer, I used this function well but not in a good way, for me, it was the round tube that I adjusted on the rectangular tube.

As for the difficulties of implementation, they are deliberate.

Thank you once again

It smells like a sadistic teacher ![]()

No, rather creative and to allow apprentices to see something other than straight works and above all to evolve.

Good night

@tonyguena I'm going to take it that way, but I couldn't help but joke!

For the adjustment unless you do it tube by tube as the gate is twisted the result of SW too!

Hence my proposal by removing material.