Hello everyone,

How do you go from a surface solid to a solid volume?

I currently have a room that is covered with surface. I'm looking for a way to thicken my piece but the software doesn't want to even though the outline is closed...

If you know how to do it or know another way to create complex volume parts, I'm all for it!

Hello

Looking at the preview, the faces don't seem to be sewn together.

If it is only one side, do an import diagnosis on the part to check that there is no discontinuity between the faces, if so, try to repair. Normally, after repair, you will get a volume part.

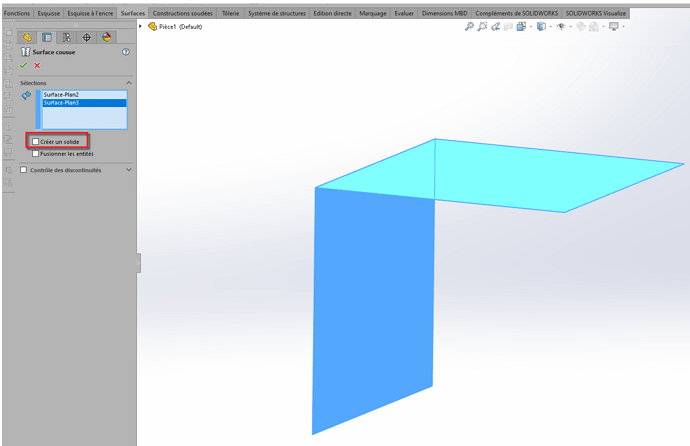

If it is several faces, you must make a "front seams" with the option to create a solid.

Ok thank you I'll try again tonight. It's several faces, but he didn't offer me the option to create a solid...

Hello

Given the surfaces, since you don't know too much about the surface, it may be hard.

Your luck is that it seems at first glance not too complicated so I would rely on the plane faces, I convert the edges and hop extrusion. Redo it it seems easily playable and you'll save your time.

may the force be with you.

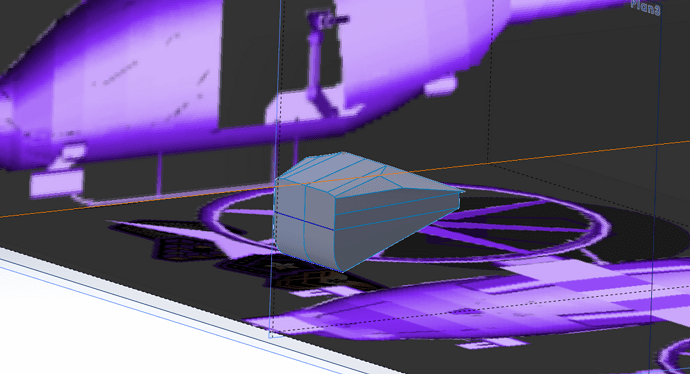

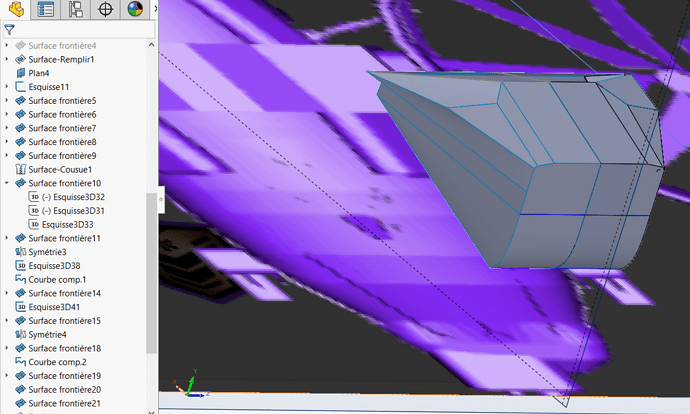

Thanks Obi-Wan, but the goal is to make a helicopter so let's say that doing DIY by removing material left and right at the end will just complicate the model if I want to make modifications. And the surface is not that complicated, after me I almost only use the " boundary surface" function where the contours are made with 4 3d sketches, and once I have made one side I do a symmetry of all the planes to get my final model.

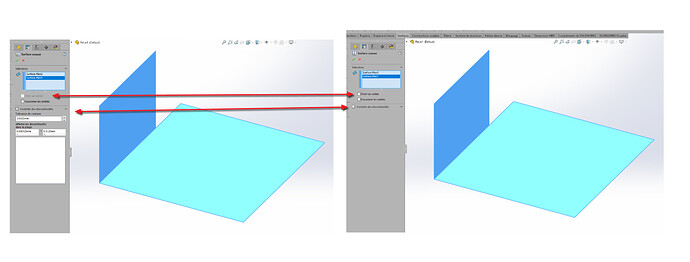

Thank you but look I created 2 faces one on xy and the other on yz and he doesn't offer me to create a solid...

Good evening

To create a solid from surfaces, SolidWorks needs those surfaces to delineate an enclosed 3D space.

The " Stitched Surface" function corrects any defects in the junction between surfaces before " converting " them into a solid if they delimit a volume. This is not the case in your example, which has only two flat faces.

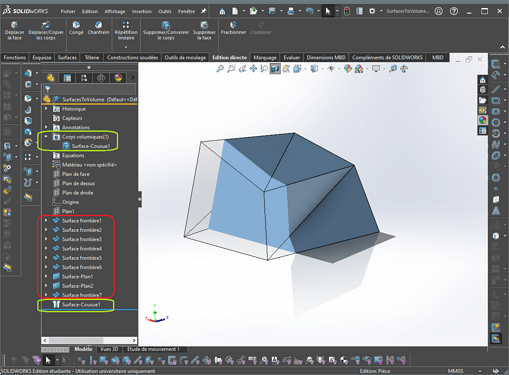

On the image below: 9 elementary surfaces to define a volume once sewn.

In a way, the " volumetric " design of SolidWorks is a trompe l'oeil: when a function proposes a volume definition of a body (extrusion, smoothing, sweeping, etc.), the volume generated by SolidWorks is the result of the surface definition of its boundaries with the outside.

The only advantage of the volume is to propose the distinction between the inside and the outside of the body.

Hello

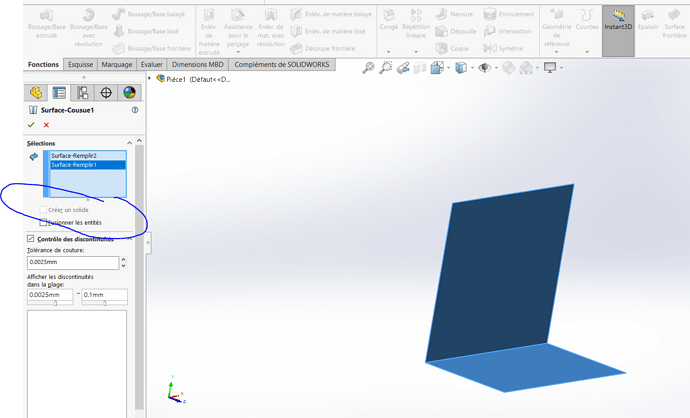

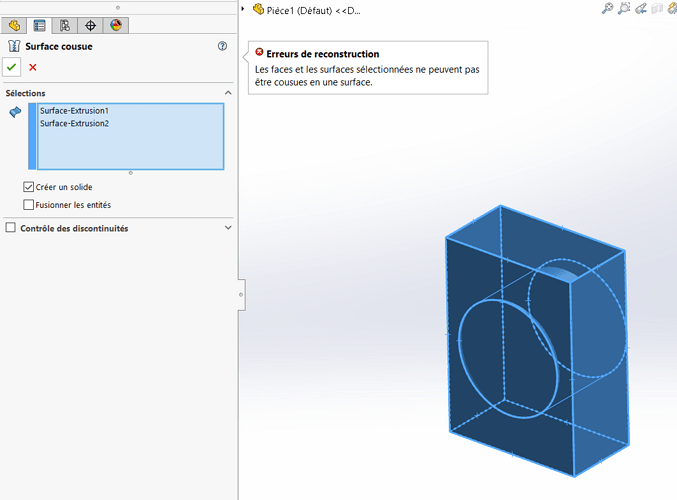

The discontinuity control must be removed to display " create a solid ".

On the other hand, if the sides do not touch, the seam will not work.

Bjr,

In this case it is absolutely necessary that all your faces are joined, no holes.

and then do as colleagues have said, sew the surfaces together to make a solid one.

may the force be with you.

hello @tous

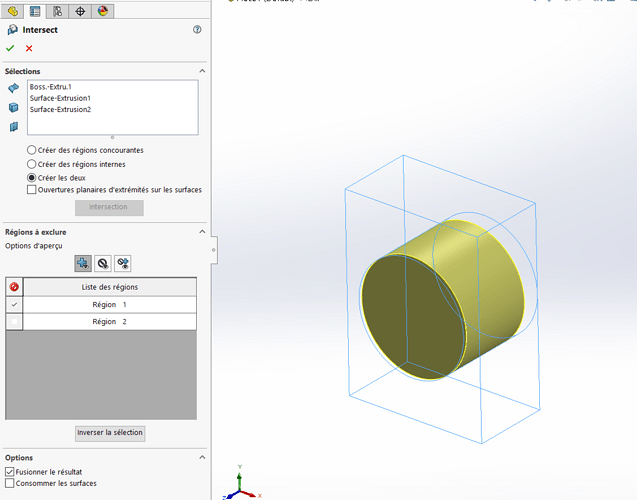

I don't do surface area, but I want to share my little experience, the sewing function may not work too if the surface overflows

If this is the case, I propose the intersection function of a volume encompassing all surfaces

Thank you, I had checked "remove the discontinuity control" and that's why it didn't work.

Thank you all also for the explanations.