Hello

I'd like to know if anyone has an easy way with Solidworks to add extra thickness

exterior to a part of more or less complex shape.

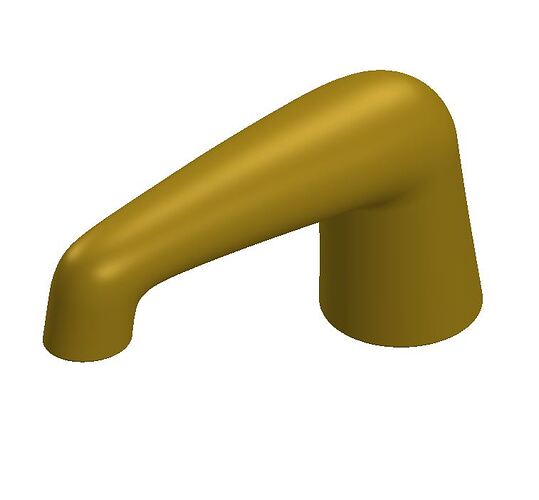

I have drawn a part in Solidworks that will serve as a model for a lost wax casting production.

The piece I have represented is of finite dimensions.

When a part is manufactured in a foundry, you necessarily know that there is a shrinkage of the metal.

So I would like to enlarge my model by about 2-3% before 3D printing it.

On the other hand, I want to make it bigger by adding extra thickness all around the model.

I tried with the ladder tool but it doesn't meet my needs, in addition to enlarging the model it gets longer and I don't want to.

So I thought of shifting the faces with the surface tools but I don't find it practical and depending on the offset thickness, there are unwanted deformations.

Otherwise I tried to make an outer shell by calculating the thickness to add because there is no percentage in the parameters. On the other hand, I have to rework the model behind it.

If anyone has a better idea, I'm all for it.

Thanks in advance

Cédric