Hi all

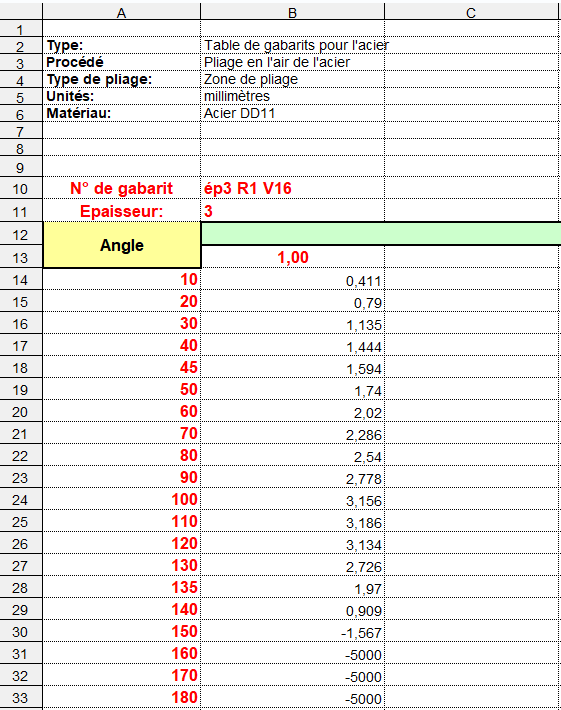

I'm having a problem with the bend table I'm using because I've traced the values to " bend zone" (values extracted from our bending software).

Indeed, with these values I manage to obtain a " .dxf " with the right dimensions in length and width compared to my folding tools.

The only problem is that the negative values of the table don't seem to work, the fold defaults and indicates that it takes the " k " factor by default.

I'm attaching a screenshot of an example table, the values of " -5000 " are a key to indicate that I'm not able to bend the associated angle.

Does anyone have a solution to this problem?

Thank you in advance very much!

I find your last values very surprising, the greater the angle the more the loss at the crease increases.

For me it is not possible to have a negative value.

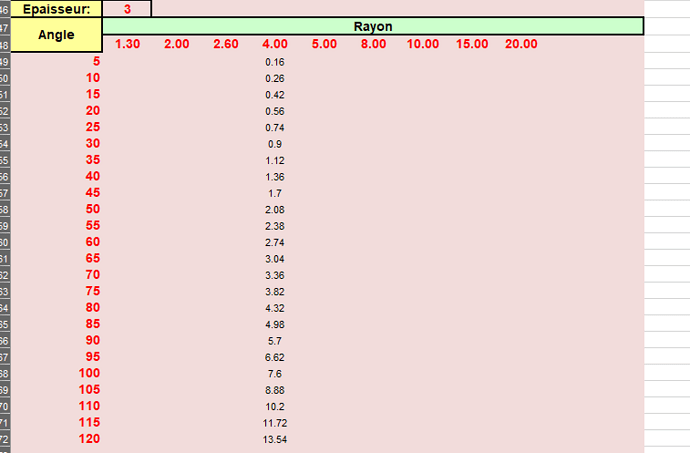

Attached is my steel table for 3mm (available on this same forum via search in excel format)

For your information, it is possible to delete complete lines for angles never used (for me I stop at 120°, not the tools for a higher angle)

Also be careful Amada (for my folding machines) starts from the outside ribs tangent for an angle sup to 90°

while Solidworks starts from the point of intersection...

Thank you for your answer,

I had carried out development tests between the trumpf software and the Solidworks developed we are good to the hundredth of a mm, the values are ok.

I simply opted for bend zones and not for the loss at the bend, the value for a given angle corresponds to the elongation of the neutral fiber. Hence a negative value for a closed angle because a deduction will be made on the dimensions of the develop.

A visiativ trainer had sent me examples of tables where negative values are also listed, so I thought that ...

Thanks for the tip of the deleted lines, very simple but nice! What is the message of solidworks if you try to design a fold outside the table?