hp08

July 29, 2021, 5:25am

1

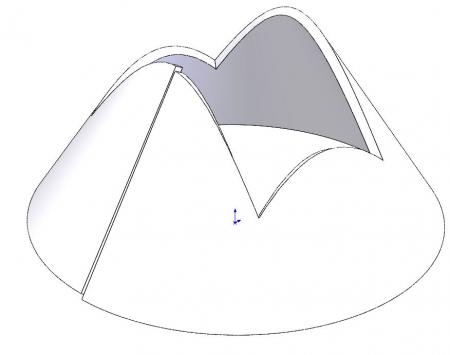

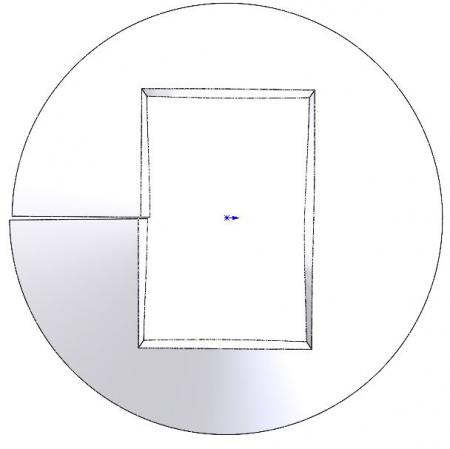

I would like to report a bug for the TOLERIE function.

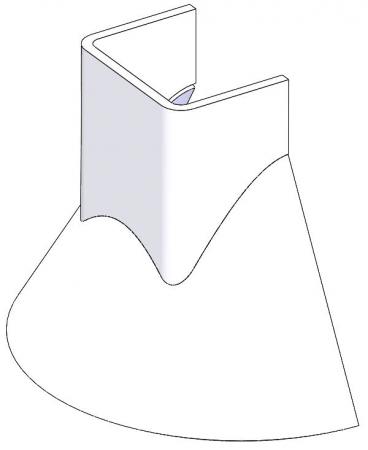

A systematic shift appears on a CONE-PRISM intersection.

The cone is defined simply with a straight line.

Any thickness is applied as well as a partial revolution at 359° for example.

Function 1 is not a problem

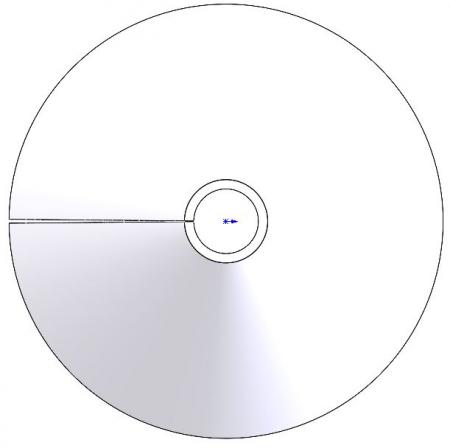

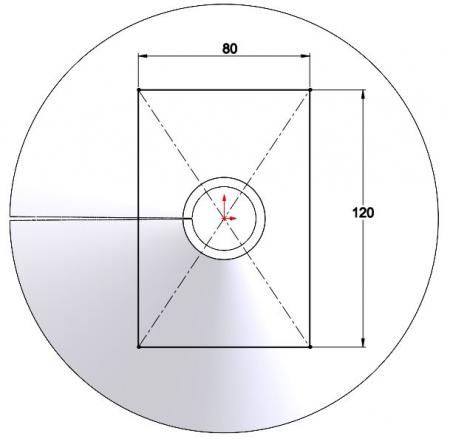

The removal of material from material is defined by means of a sketch in the top view.

The odds are not important...

The result is correct and in line with expectations

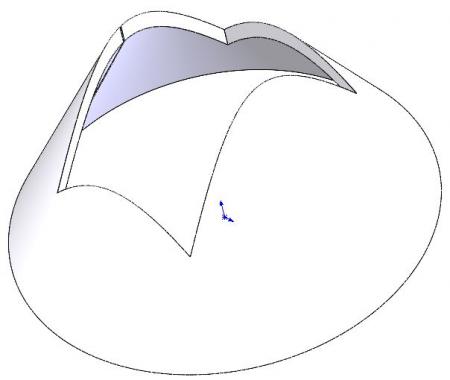

The problem appears when using the sheet metal function

The thickness appears correctly, however an abnormal offset systematically appears.

There is a bug.

What is the solution ?

Do you have a lead?

Thank you

part2.sldprt

Hello

You are on the designer's self-help forum and not on a Visiatv after-sales platform to report the dugs.

2 Likes

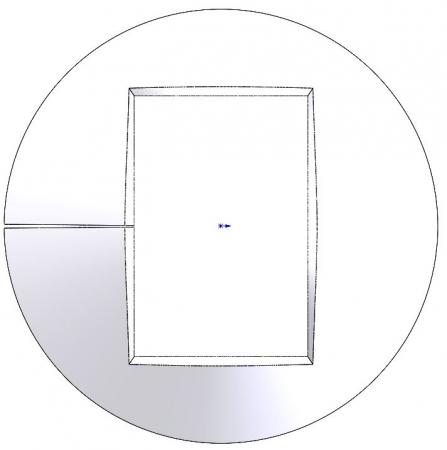

To fix the bug, simply move your material removal after folding and check the box Normal material removal and the bug disappears. see PJ

ac_codra_427.sldprt

3 Likes

hp08

July 29, 2021, 6:44am

4

Thank you for your quick response.

The solution gives me a lead that is not totally satisfactory but I will test.

It is the relative position of the thickness that poses a concern for the docking to be perfect with the tube.

I test and thank you again for your solution.

The position of the thickness reflects reality because your cone will be laser or plasma cut and the normal material removal allows for a perpendicular cut to the thickness as for cutting. If you don't want to have that, you'll have to go through a machining operation.

ac_codra_427_-_1.sldprt

3 Likes

Hello

As ac cobra 427 specifies very well that I salute in passing, the laser cut will be perpendicular to the "unfolded" part.

2 Likes

hp08

August 3, 2021, 5:03am

7

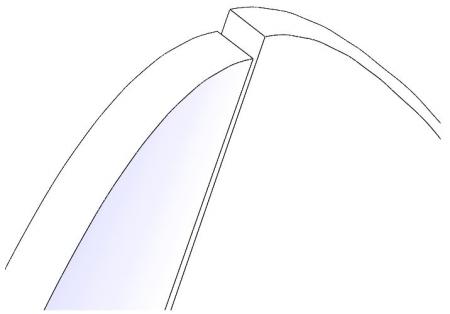

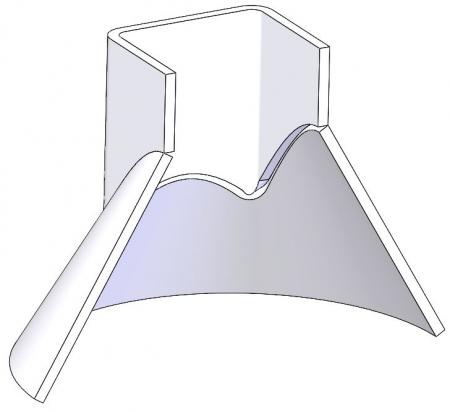

After testing several solutions, I give you my conclusions.

First, I wanted to have a natural chamfer docking between a cone and a rectangular tube.

The solution chosen gives us parts that conform to the above clichés, but the parts are not developable.

To obtain these coins, you have to work around the software's problems and bugs.

We have a beautiful image but this one is useless.

As mentioned in my first message, SolidWorks is stuck on this type of part.

I am attaching my assembly file.

Thank you for offering me solutions.

cone-tube_rect_v3.zip

gt22

August 3, 2021, 12:12pm

8

Hello @hp08

Post your parasolid parts and assembly

I think that you should not make a cut before but after the installation of the tube

Create your tube via extrusion to the surface of the cone via an offset sketch

and only then pierce the cone

Take each piece individually

cut them and transform them into sheet metal work

and unfold them

@+

1 Like

Hello hp08,

I don't know the section of your tube, but it seems to me that it is possible to cut inclined cuts via the "laser tube"! As a result, you have two pieces that go together quite well!

Kind regards

hp08

August 3, 2021, 2:39pm

11

Continued with the pieces

piece3.x_t Part2-v4.x_t

Hello

Attached your fold-out parts; They could not unfold because your sheet metal bodies were removed and replaced. For the cone, the sheet metal is replaced by a body of revolution so not unfoldable and for the tube it was the lower part in sheet metal that you replaced by the upper part not converted. see PJ

ac_cobra.rar

2 Likes