Hi everyone

I have a quick question for the community.

I have a bookcase with corks, nuts etc... that I would like to add simply and easily in an assembly.

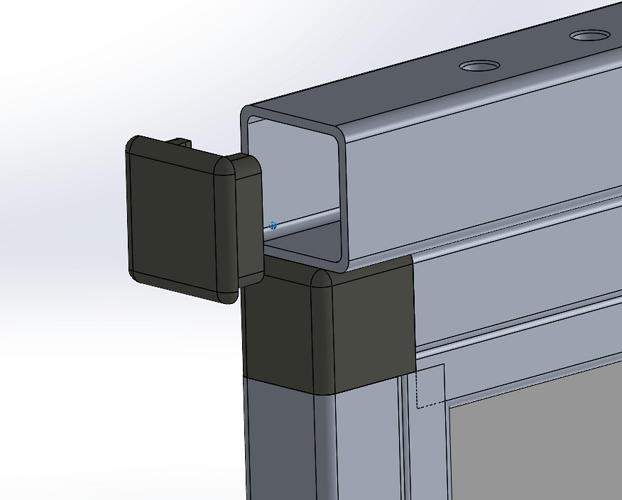

For example, I create a part in a mechanically welded square tube that I add to an assembly.

In this assembly I would like to slip caps or nuts so that it positions itself automatically.

I was thinking about the " constraint reference" function but I don't see how I could do it.

Thank you in advance for your help and I wish you a good day

1 Like

Thank you for your answer but it doesn't help me.

I've already used constraint references in my library to assemble std parts together. It works perfectly.

But I spend a lot of time putting nuts or plugs in mechanically welded structures and I would have liked to find a solution to save time.

Basically, I create a mechanowelded tube and I would have liked to plug the ends quickly with my library components to avoid putting 3 constraints each time per plug

Indeed for automatic constraints with several reference faces it does not work (only one of the faces is taken into account, the 1st in order)

The only effective stress references in my opinion are when you select a circular edge l(circular edge is put in ref on a circle and on one face at a time.

Otherwise for me the other attempts, we end up in systematic failures.

Proposal 1, look at magnetic constraints if it is feasible (not tested).

Example video:

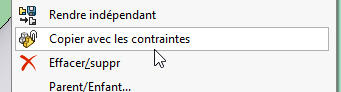

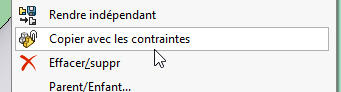

Proposal 2 constrain 1 piece and copy with the constraints:

1 Like

Does not work for nuts and plastic tips as requested, @Silver_Surfer , only for a piece of sheet metal.

I join plastic parts in aluminum  tubes so my structure is with the mechanically welded function that I adjust to put nuts or plastic caps

tubes so my structure is with the mechanically welded function that I adjust to put nuts or plastic caps

Hello

Constraint references can work but you have to get close to isostatism if you want it to work well.

My advice is to have the laying plan in ref 1, an edge in ref 2 and a point in ref 3.

Otherwise the nice thing once the first tip is placed (with the 3 constraints as explained above), is to possibly use the ' copy with constraints ' function: it's very fast.

An alternative to the stress level could be: tube end plane, tube axis and a plane/edge for orientation (with parallelism for example). Don't hesitate to add the tube axle in your end cap parts.

Thank you, I'm going to test this idea but I'm afraid I don't have the axis of the profile given that in mechanical welding you can position the profile according to different points ...

Thank you for the advice, I'll tell you again next week

So we should start with the basic idea