Hello

We are asking ourselves the question of whether or not to add screws in the assemblies of our designs to help with the assembly work.

We have several fears: On smaller sets, the 3D is quickly overloaded and the 2D no longer opens (Toolbox SW). We therefore doubt the possibility of adding the screws on a complete machine.

Does anyone do it in their blends without problems? Is there a way not to overload the drawings?

Thank you very much for your help

Justin

With us, it is mandatory to design the screws (automatic control via 3D and request from the high authority)

No problem-> No

Of course, this considerably weighs down our machines, additional constraint and graphic resources when opening.

On very large assemblies, between 50,000 and 100,000 parts, this sometimes even becomes problematic.

I'm even wondering about creating a configuration of each machine where all the screws would be hidden to lighten the graphic resources. (impossible or too complicated deletion because inserted in the different sub-assemblies).

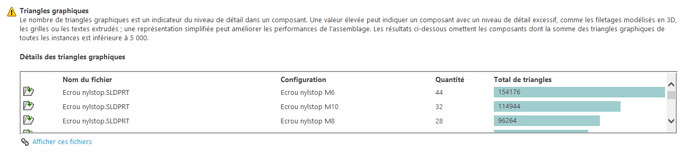

As proof that this can be a problem:

Even on this small assembly we can see that the graphic resources (triangles) are monopolized by the screws.

On the other hand, the advantages:

- screws defined on the plan (not at the will of the fitter following the machine)

- Automatic order for us (via BOM)

- Less risk of screw heads hitting a room or unmountable.

Hello

It is true that when we want to make our conceptions as real as possible, we alordi our assemblies.

For my part, it's not the screws or the number of parts that slow down the opening or even crash solid, but the perforated sheet metal on specific shapes. To do this, I make a light configuration of the part to be able to open the assembly without problem for certain jobs.

Wouldn't it be possible to have a light version of your screw or other for me to charge (without thread, without footprint for example)?

The lightweight version of sub-assembly does not help or in complex assembly?

Hello!

It's certain that the screws in large assemblies don't go in the direction of performance!

Despite everything, it is clear that it can avoid some typos in the editing.

I have gotten into the habit of creating for my largest sub-assemblies a "WITHOUT SCREWS" configuration in which the screws are removed.

The solution is not ideal, but it helps.

How do you proceed @c.vuillaume for the configuration without screws, out of curiosity?

All your screws are in the main assembly or different confi in the sub-assemblies?

The lighter or complex versions are not very useful in my opinion, each time you open an assembly in these modes you end up having a part or a sub-assembly to modify and the time you have saved in opening you waste it editing the part or the AS in the editable mode or in the update of the open assembly.

Even if I'm not a fan, no choice for us, everything is open in solved...

The screws are in my sub-assemblies, it would be far too tedious to add it directly to my large assemblies.

On the other hand, it still requires a bit of rigor and time in the sense that you have to add the configurations to each level of subassembly and to keep your configuration up to date if you have changes afterwards. But when you've gotten used to it, it's done well.

To lighten the procedure, I invite you to focus on sub-assemblies with a large amount of screws. If you have a subset with 2 screws that is only once in your general set, it's not necessarily relevant to create a configuration for it.

Other I make a folder of screws that I hide or delete with the function in the tree (in gray) that you can cancel not the rest. So it goes quite fast when you need it.

Hi all

With us, screws are mandatory but we don't use this f**king toolbox.

We create our own library of fasteners by type, size and material, because what weighs down the performance is the number of configs to load.

For example, for H-head screws, we have different parts for:

H-M8 zinc-plated, H-M8 A4, H-M10 galvanized etc (only the lengths are configs in these parts)

which greatly limits the reconstruction time.

In addition, we have recently been trying Parts that bring together Screws+Washers+Nut in the same room (in multi-body mode)

This gives the end the same number of bodies but not the same number of components.

Example:

An assembly with 200 bolt assemblies normally gives us 200 screws + 400 washers + 200 nuts. That's 800 components compared to 200 with this new technique.

Bolts are represented in their reality but the performance is optimized.

@nlebatteux I also have a screw folder with automatic creation via macro.

But the problem as for @c.vuillaume is the rather numerous sub-assemblies in which the screws are present (very few screws in the main assembly of a machine).

And creating the config without screws becomes longer than the time I then gain in opening., so not valid for me. (I had even created a macro to do it automatically but it was too complex and too long to do for the time saved)

Hence the tests I have to do in a config by hiding the screws rather than deleting them because by hiding it doesn't propagate to the sub-assemblies (but still spares the graphics resources)-> To be tested on a big assembly

Hello, we also work in personal bolts.

Are you in the 2024 version?

Hello, as far as possible prefer the repetition of components, it lightens the files a little ![]()

Thank you all for the answers, it's interesting.

If I summarize, there is no really viable way to add the screws to the assemblies without weighing down the machines too much but some ways to limit the damage: Make your own library with length configs, assembly configs with/without the screws, use repeats.

I'm going to dig a little deeper in terms of solidworks config because I think that if I try to open the assembly of 50k parts of sbadenis, the pc will still run next year if it doesn't crash.

Hello

It's clearly worth it to simplify the volumes of screws as much as possible. When you see the number of triangles of nylstop nuts you tell yourself that it deserves to spend a little time on it (especially if you put it everywhere in your assemblies).

Also beware of the screws imported from the internet: if by misfortune the supplier has engraved his logo on it, you will face serious performance problems.

There is also the possibility to play with the display states (but then you won't see the screws anymore even if they appear in the nomenclature).

no, we are under 2023 SP4