Hello

I realized a problem during an assembly using coaxiality constraints.

For simplicity, I am sharing with you the problem with the use of two very simple pieces: Two plates each pierced with two holes, named Piece1 and Piece2.

Part1, red in color, has two 50mm center distance holes

(Attachments - A)

Part2, blue in color, has two 50,001mm center distance holes.

(Attachments - B)

When assembling these two plates, I apply a coaxiality constraint between the first hole of Part1 and the first hole of Part2.

The same goes for the second hole.

Despite a delta of 0.001mm, coaxiality is well accepted (no error message):

(Attachments - C)

I now change the center distance on Part2 to 50.0011mm:

Coaxiality is no longer accepted:

(Attachments - D)

So it seems that Solidworks is forcing a coaxiality constraint without triggering an error if the center distance delta is less than at least 0.001mm.

Until now, I very often carried out perfect coaxiality checks by applying a coaxiality constraint between all my holes, i.e. by over-constraining (hyperstatism) my assembly. But at least that way, if a coaxiality was displayed in red, I knew I had a mismatch to correct.

Now that I realize this uncertainty, I have to check my alignments one by one with the measuring tool which gives with precision, the difference in coaxiality between the holes.

Do you have a solution to reduce the coaxiality uncertainty to 0mm? That is, make Solidworks display an error message and a coaxiality in red if the delta is nonzero?

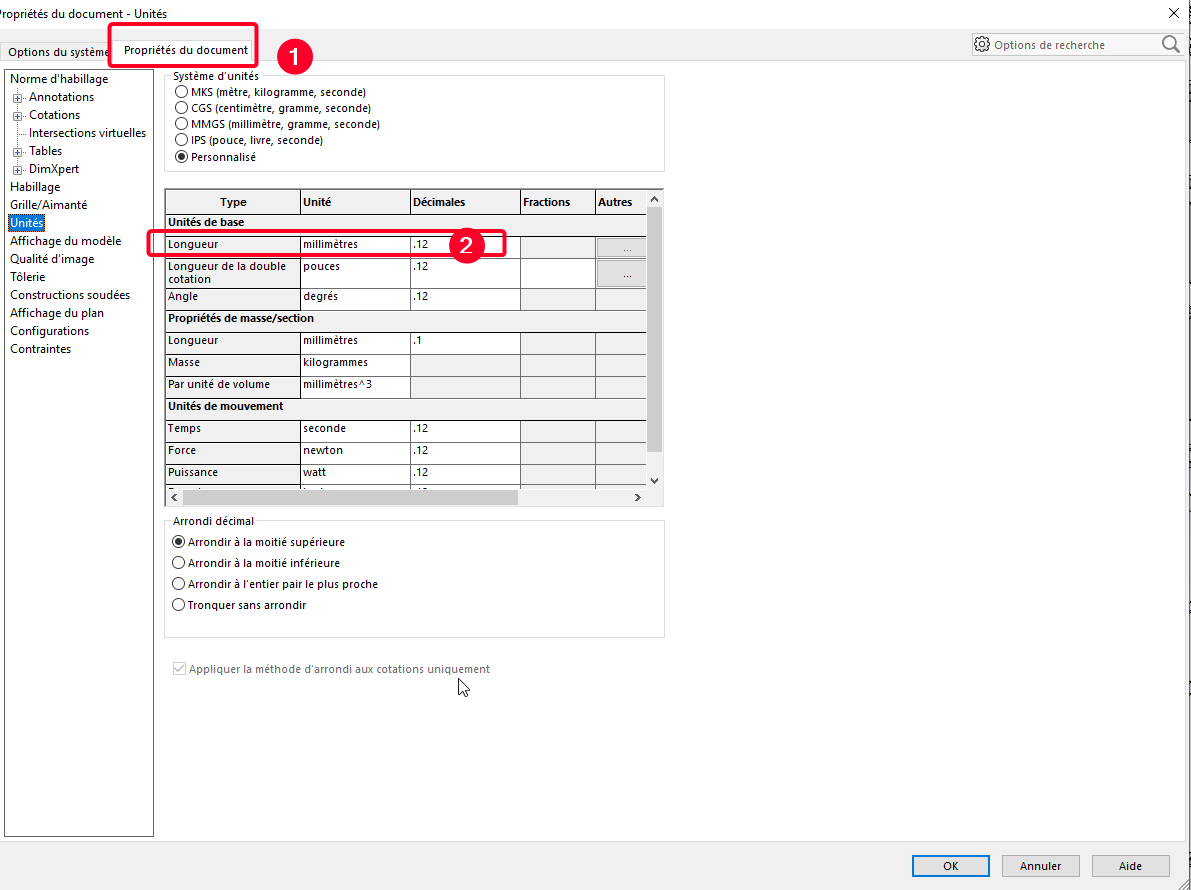

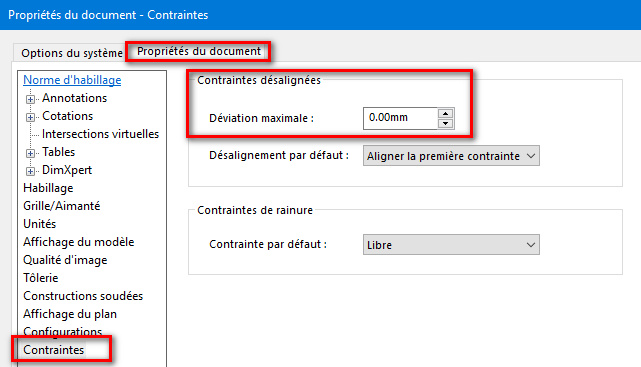

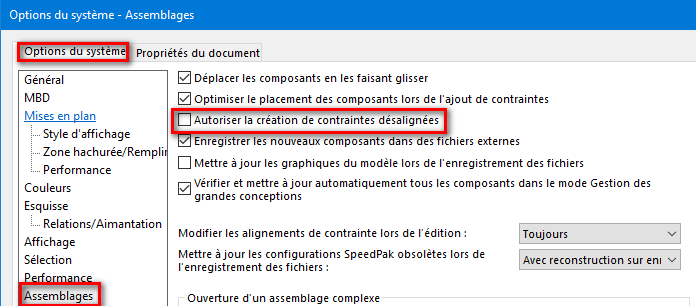

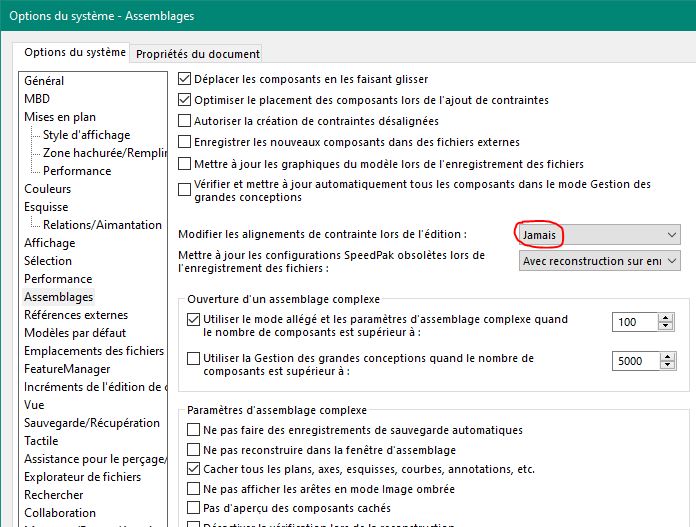

NB: The only info I could find on the Solidworks help is the " Allowing misaligned coaxial stresses ":

(Attachments - E)

https://help.solidworks.com/2021/french/SolidWorks/sldworks/t_allowing_misaligned_concentric_mates.htm?format=P&value=

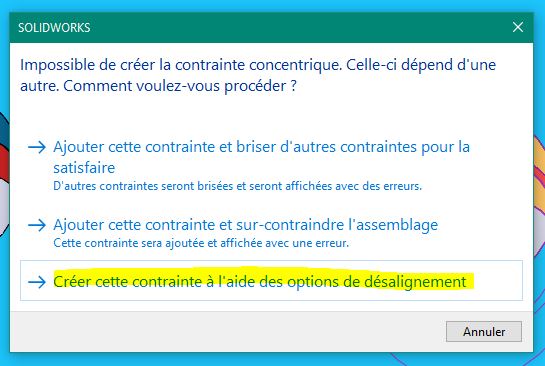

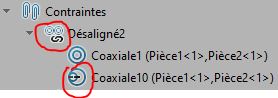

But it doesn't seem to be my problem because the two " misaligned " coaxial stresses should then appear in this form:

(Attachments - F)

Which, as a reminder, is not my case:

(Attachments - G)

Thank you in advance for your help.

Kind regards

Parts jointes.pdf (494.6 KB)