Hello

Indeed thank you @tous ;-)

After a long wait with my sister Anne - who didn't see anything coming either - we are finally informed of the size of the rubber door.

But alas, as the requester indicates that "the simulation on SW is ok" implied to be over, we are stuck since the calculation or more precisely the simulation of the deformation of the rubber can only be done with SW Simulation or by calculations with no cockchafers.

I have asked several times for detailed details, but in vain on the "sliding curtain track". The weight, the nature and the method of attachment to the rubber. We were just told that there was an extra thickness of rubber at the points of friction in the side guides.

As well as saying that the side guides are fixed, it makes us -as my grandmother used to say- a beautiful leg, as long as we don't know the exact shape of these guides.

In other words, if the guide is a simple open U, nothing prevents movements in X and -X, which is sure to make the curtains come out of the side guides.

So without a cross-sectional view of the side guides (which should look like a square or rectangular tube with an opening of a few centimeters in radial) and an image of the horizontal tensors, no simulation, no calculation at the mano not possible for me but that some Xs would know how to do.

In addition, without having the characteristics of the rubber, namely the name of the supplier and the exact reference of the rubber , we will not have access to the information of the three friends Hooke, Poisson and the young Young.

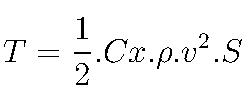

But what I can tell you without having read in the coffee grounds is that it will only take 20 knots of wind for the curtain to more or less come off the rails. From 50 to 60 knots of wind everything will be off the rails and will hit and destroy everything within 18m on either side of the door including the roof until the winding tube gives way and turns into destructive UFOs that will destroy, nearby, the rabbit hutch of Père Jules

Also destroying the coffee machine, the canteen, the toilets and the owner (ranked in order of importance).

@tous I inform you that an indefinite strike notice is being given on the grounds of "clear withholding of information and obstructions to the manifestation of the clear light that was supposed to tear apart the darkness of ignorance.

Kind regards

![]()