HELLO AND HAPPY NEW YEAR,

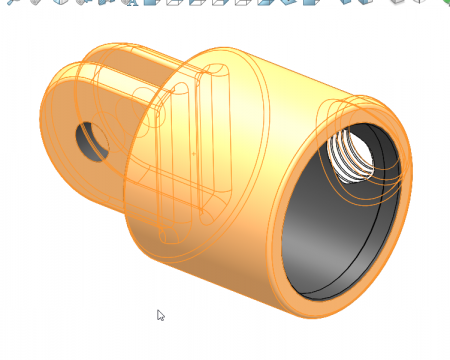

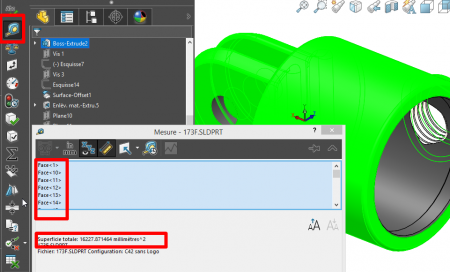

You can select all the faces in question using the Ctrl key and with the measure tool you will have the area displayed.

CDLT

HELLO AND HAPPY NEW YEAR,

You can select all the faces in question using the Ctrl key and with the measure tool you will have the area displayed.

CDLT

Thank you for your wishes, I also wish you a happy new year.

I know this function, however in this way we also take into account the faces that will be covered (and what's more, it's long...)

I found this tutorial on Top Solid and I imagine that we must be able to do the same thing on Solidworks right?

https://youtu.be/SYT7s3HBLvI

At the limit that the model does not contain any orifice (it is said that the software rotates and then generates the faces by projection).

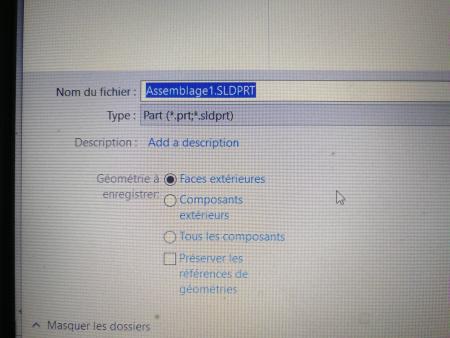

If this is the case, I suggest going through an assembly, save in part with the option of external surfaces,

Hello

if it's on a sheet metal part, it is necessary to right-click on the unfolded view, then annotation and properties of the list of welded parts and everything is displayed, see PJ

For my part, in an assembly, right-click, select filter, filter the faces, then tool, evaluate the mass property and look at the area.

This avoids selecting face by face what is very long.

And the ideal is even to make everything in stainless steel so that you don't have to worry! ;-)

@ac cobra 427, ok for sheet metal but not for parts composed of sheets and tubes...

@sbadenis thanks but this selects all the faces, including the inside of the tubes, and the overlapping faces.

Your method of selecting faces also works for a sldprt file, I checked with 2 sheets of 1000x1000x0.5 superimposed, I have a result of 4 M²... when there are only 2 M² to paint...

Hello

or for open or closed parts the tangency of the faces can be used as follows with sufficient precision for painting.

then measurement tool

@soring, thank you, indeed it's faster to select the faces, but it doesn't solve the problem.

I think that ideally you should be able to create an envelope around the part, like on Top Solid, and I will find it crazy that you can't do it with SW

I thought my method did the job like topsolid no, why didn't it work?

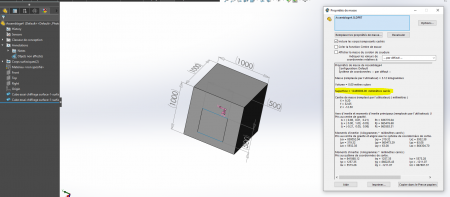

@Lynx, there must be a bug anyway... For this cube of 1000x1000x1000 counting the interior faces, before the 500x500 boss, we have 12m².

we should have practically the same result after this boss, but we have 500mm² more... weird

I can't keep up with 1x1x6=6, where does 12 come from

Can you describe this test object better,

Otherwise there's this macro that uses defeature and adds a property with the area in the room or AS.

But the same thing does it make a distinction between total surface and external surface:

https://www.3dcontentcentral.com/macros/Macro.aspx?id=341816

I've looked at how it works but I'm not sure if it's modifiable to take only the exterior surface.

For the Topsolid function you won't find the same one identically under SW.

That's precisely the problem, the cube being hollow, all the surfaces are counted, even those inside the cube, hence the 12 m².

Just like the inside of the tubes in the example of the canopy, if we know it's not a problem, just divide by 2.

On this cube, which I created just for testing, I note a problem, in principle by adding a sheet metal in surface, the surface to be painted, should not change.

But there is 500mm² more... which is not coherent, and for the time being, in this case there should have been 2x500mm² of reading because it detects all faces.

weird

Another solution that is approaching but only on one part:

https://hawkridgesys.com/blog/solidworks-representing-paint-coatings

Edit another method but always for all surfaces:

https://www.cati.com/blog/2015/03/how-to-output-surface-area-for-each-part-in-solidworks/

The return message appeared late, oO

@jlebas you said that the internal faces are counted, did you check this option,

In the previous example, I used tubes, the result was just no need to do any additional calculation,

@Lynk, yes I followed your method and checked the box, I get the same result. I think this is the most effective method but it still doesn't handle overlapping surfaces