Hi all

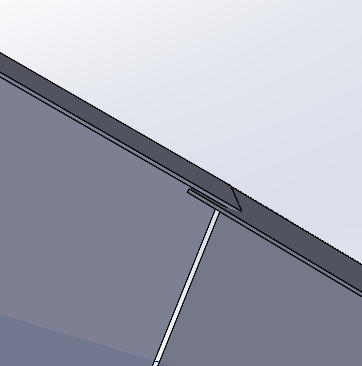

I'm looking for how to remove material from a ridge fold, because when I make two edge folds next to each other, the edge folds collide.

How can I avoid this collision?

Hi all

I'm looking for how to remove material from a ridge fold, because when I make two edge folds next to each other, the edge folds collide.

How can I avoid this collision?

you have to edit the sketches of the fold and cut

Hello

If the 2 folds are on the same part and identical (angle, radius, length...), make them in the same function and SW will take care of the rest...

Kind regards.

Hello

As @a.eriaud says, Try to make (if possible) several folds in the same function

Normally, adjustments will be made automatically

Kind regards

David

Hello,

Can you provide us with your piece?

Just to see how it is built... It will be easier to help you.

I just reviewed your play

I think you will be forced to go through material removals on each of the 2 plies (folded sheet metal 7 and 8) or there are extruded removals 3 and 4

These 2 functions make the faces not coplanar and so even by grouping the edges into a single function, it can't find a common face

Kind regards

David

Thank you David, I can see the problem with your explanations, but I can't seem to do a material removal that solves the problem.

Can you point me a little more?

You have to edit the sketch of your 2 folds and add an angle of about 75°.

This way the sheets no longer cross each other.

@ronathan to the solution

I'll just add that you can remove the dimensions on that you added on the 9 fold (662 and 0.78 and reconstrain on the ends: it's not useful to reduce the spaces and for me it creates an error

Kind regards

David

Ok thank you ronathan and David for these clarifications, now I don't have any more collisions. ![]()

Hello

This model lends itself better to volume modeling at the beginning and then conversion to sheet metal. More precise. The interference would be resolved automatically.

You can be a little more precise soring, if I understand what you're saying.

Is it that I should have drawn it with sharp angles in standard volume modeling and used a function to turn it into sheet metal afterwards?

I didn't think it was done.

Yeap. It is done. Just practice on a simpler piece.

The function is... "Convert to sheet metal" ![]()

The fixed face (the face from which the folds are linked) must be indicated, the edges of the model which will become folds. Other options allow you to correct the default values of sheet metal thickness, notching, etc. That's why you have to train a little.