Hello

I'm in the process of setting up a meter and one thing saddens me.

When creating, my piece, taking a new number works perfectly and the file is saved with the right values.

However, on my various projects, I never take a reference to the creation of the piece, because I don't know if I'm going to keep it or delete it.

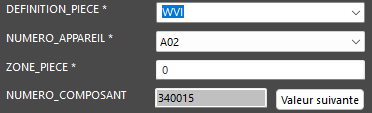

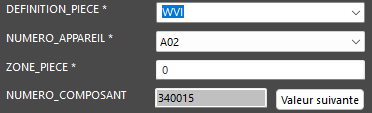

Once the project is finished, I add my parameters:

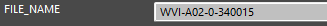

This is well taken into account:

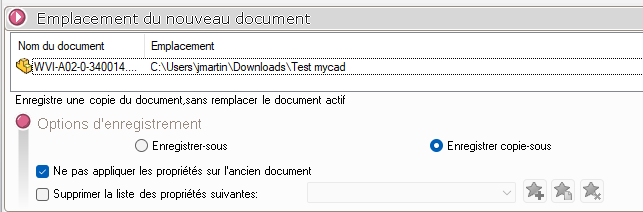

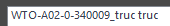

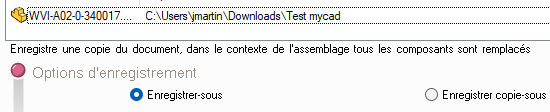

Except here during validation:

The software absolutely wants me to create a copy via the menu:

How do you proceed with a meter?

My goal is to avoid taking a number in a vacuum if I don't keep the piece in my asm.

And if you uncheck that, it might allow you to save as rather than save copy-as, which would make sense.

1 Like

Both save a copy without modifying the existing part.

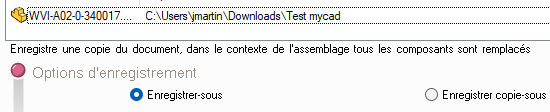

Is the piece already recorded?

If this is the case, it is normal, it cannot rename a file that has already been created and opened.

1 Like

Yes.

I usually put the parameters, on the parts and assemblies, at the end of my project.

Today, we use an Excel file that we fill in manually to take references, it is a source of error and not practical for several people at the BE.

Before using the counter I also created my pieces without parameters, now I have gotten into the habit like my many other friends to do the opposite. (Be of + 20 people)

Basically, new parts I draw what I need and as soon as I want to save it I go through the counter. The registered button is no longer used during the 1st recording.

And too bad if the part is then deleted or not used it doesn't matter, we accept to have a "hole" in the numbering.

2 Likes

Okay, I'm going to propose that way of doing things. Thank you

You use the description column

where it's all in the name

?

Because I saw that the description part is easily changeable once the increment is validated.

What bothers me is that our files are created without this column.

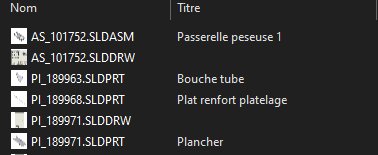

For us much simpler Simple type number PI_000123 or AS_000123 (part and assembly) File name for IFs in the library and custom property (via smartproperties) for description and other information depending on the type of part, assembly or FI (supplier name, IF code...)

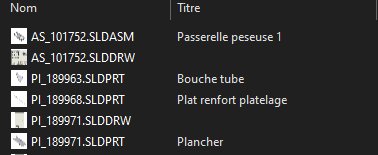

Here's an overview:

For me, the name of the project, the customer and the exact quantities for the affiare are automatically injected via Integration and export of the Excel BOM into the MEP and exported as a pdf for printing.

No number per business, or customer but unique number. (so simpler)

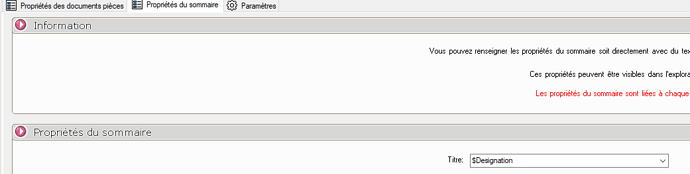

Edit: to have the title = Designation checked this and put $Description (for us designation)

2 Likes

Thanks for the info. I will start with this way of doing things.

Taking reference to each creation, and that's it.

1 Like

![]()

![]()