Hi all

I am faced with a problem of " propagation " of part stresses through several assemblies and I do not understand what is blocking.

For context, I've been self-taught for 9/10 months (and it's starting to be a problem) under Solidworks after 15 years under Creo. This sometimes plays tricks on me in the design intention, which is not always transposable to SW.

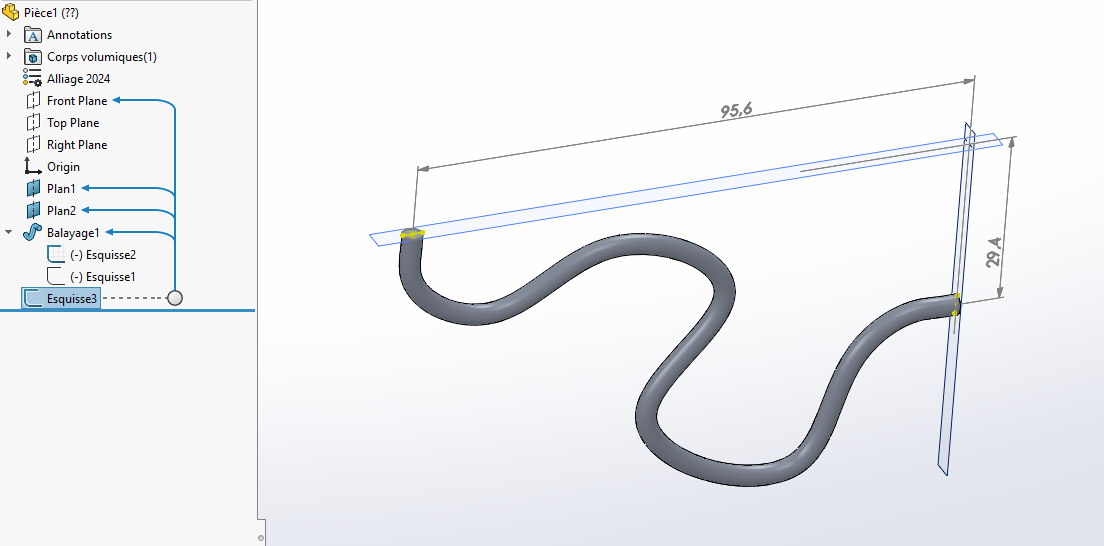

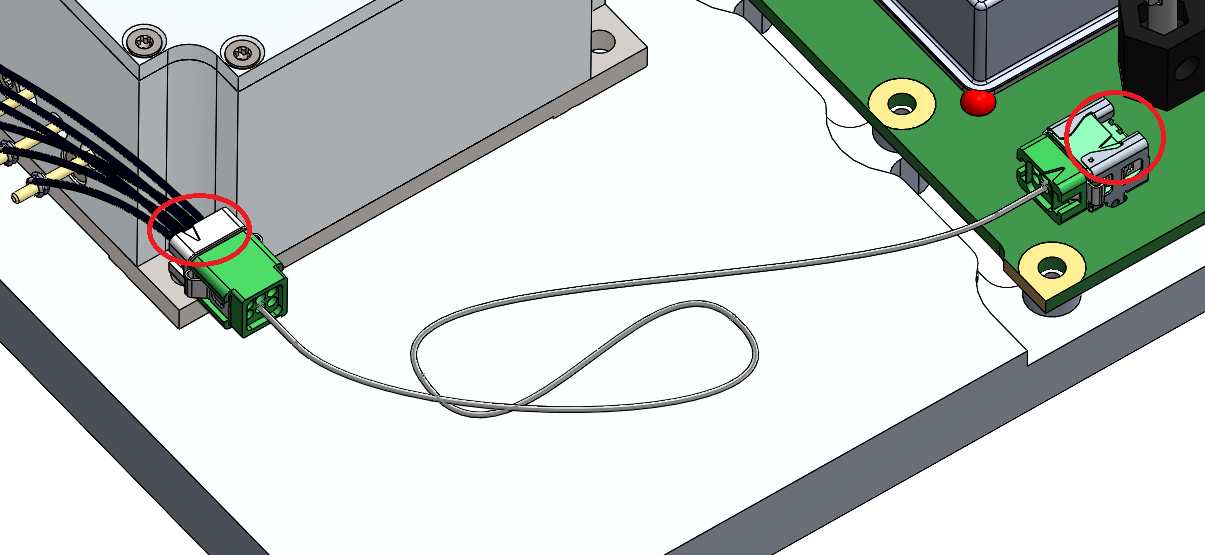

My problem is to represent a cable that connects 2 connectors in red:

My 1st attempt was to create a " cable " sub-assembly with the green connectors whose 1st shaft connector is totally constrained, then to assemble this S/E " Cable " in my head assembly. By wanting to position the connectors by constraints at the 2 ends, SW constrains the 1st connector but impossible to move the second, I have an error message asking me to break links or to constrain it. What for? Did I miss something? This 2nd connector was not constrained anywhere...

My 2nd attempt was to assemble the 2 connectors where they need to be in the head assembly and then to create an S/E (function in the context menu). It worked physically but all the constraints in place blew up! I left it at that, but the situation is not sustainable.

What do I do wrong in SW to not benefit from this flexibility of constraints regardless of the part, regardless of the level of assembly?