Hello

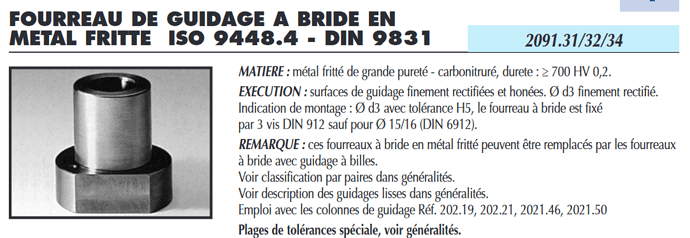

I have just selected a ring to make a guide column on a press.

I will arrange my two columns to start by respecting a condition of no buttresse, then I will proceed with my simulation, but this is where I have a doubt about my decoding of the designation of the subject of the technical doc.

In summary, 700 HV 0.2 indicates a high surface hardness for a steel material, measured at a penetration depth of 0.2 mm

To calculate the elastic strength (Re) from the Vickers hardness (HV), I use the following formula:

Re = 0.36 x HV

Thus, for a Vickers hardness of 700 HV, the elastic strength would be approximately:

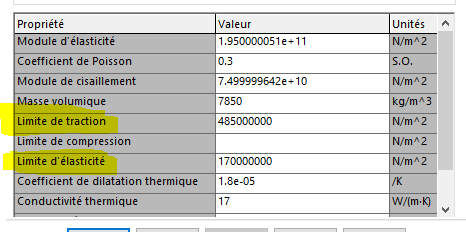

Re = 0.36 x 700 = 252 MPa

And we place ourselves on the tensile strength

To convert 700 HV 0.2 to tensile strength, I use the following formula:

Tensile strength (N/mm²) = (HV * 0.0142)²

By applying this formula, we obtain:

Tensile strength (N/mm²) = (700 * 0.0142)² = 1384 N/mm²

How do you combine these two mechanical characteristics of this material in the SOLIDWORKS material base?

Thank you in advance for your help.

Spectrum.