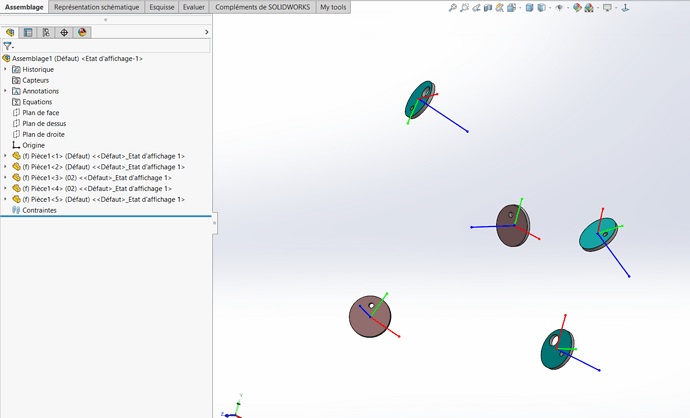

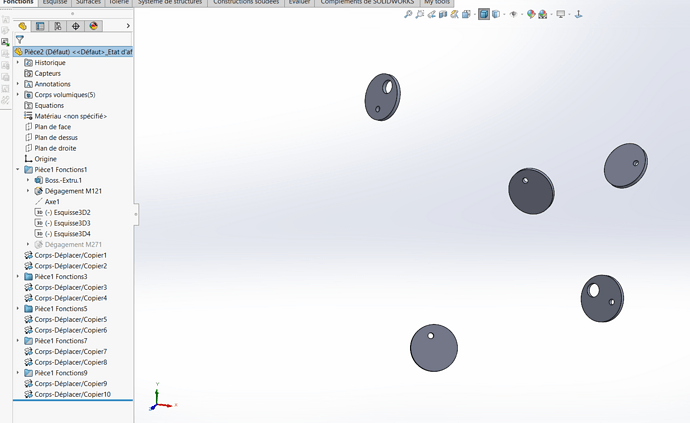

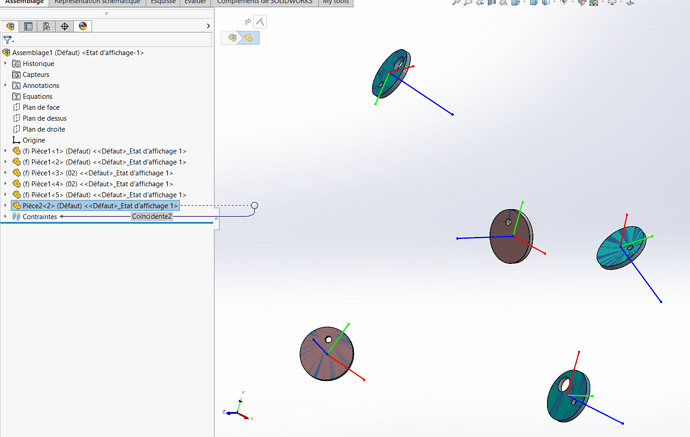

Si joint une description des points

(merci a @Rim-b qui a évoqué la fonction principale)

Assemblage1.zip (355,9 Ko)

Option Explicit

Dim swApp As Object

Dim swmodel As ModelDoc2

Dim swpart As PartDoc

Dim swassembly As AssemblyDoc

Dim swMathUtils As SldWorks.MathUtility

Dim featmgr As FeatureManager

Dim pbodies As Variant

Dim selmgr As SelectionMgr

Const PI As Double = 3.14159265359

Sub main()

Set swApp = Application.SldWorks

Set swMathUtils = swApp.GetMathUtility

Set swassembly = swApp.ActiveDoc

Set swmodel = swApp.NewDocument("C:\ProgramData\SOLIDWORKS\SOLIDWORKS 2022\templates\Pièce.PRTDOT", 0, 0, 0)

Set swpart = swmodel

Set featmgr = swmodel.FeatureManager

Set selmgr = swmodel.SelectionManager

Dim comp As Component2

Dim vcomp As Variant, vc As Variant

vcomp = swassembly.GetComponents(False)

For Each vc In vcomp

Set comp = vc

Dim pos As Variant

pos = get_position(comp)

pbodies = swpart.GetBodies2(0, False)

swpart.InsertPart3 comp.GetPathName, 512, comp.ReferencedConfiguration()

select_bodies get_bodies(swpart, pbodies)

featmgr.InsertMoveCopyBody2 0, 0, 0, 0, 0, 0, 0, pos(5), pos(4), pos(3), False, 1

select_bodies get_bodies(swpart, pbodies)

featmgr.InsertMoveCopyBody2 pos(0), pos(1), pos(2), 0, 0, 0, 0, 0, 0, 0, False, 1

Next

End Sub

Function get_position(comp As Component2) As Variant

Dim pos(5) As Variant

Dim swTransform As SldWorks.MathTransform

Set swTransform = comp.Transform2

Dim r11 As Double, r12 As Double, r13 As Double

Dim r21 As Double, r22 As Double, r23 As Double

Dim r31 As Double, r32 As Double, r33 As Double

Dim r41 As Double, r42 As Double, r43 As Double

Dim r44 As Double

r41 = swTransform.ArrayData(9)

r42 = swTransform.ArrayData(10)

r43 = swTransform.ArrayData(11)

r44 = swTransform.ArrayData(12)

pos(0) = r41 * r44

pos(1) = r42 * r44

pos(2) = r43 * r44

Set swTransform = swTransform.Inverse

r11 = swTransform.ArrayData(0)

r12 = swTransform.ArrayData(1)

r13 = swTransform.ArrayData(2)

r21 = swTransform.ArrayData(3)

r22 = swTransform.ArrayData(4)

r23 = swTransform.ArrayData(5)

r31 = swTransform.ArrayData(6)

r32 = swTransform.ArrayData(7)

r33 = swTransform.ArrayData(8)

If r13 < 1 Then

If r13 > -1 Then

pos(3) = atan2(-r23, r33)

pos(4) = asin(r13)

pos(5) = atan2(-r12, r11)

Else

pos(3) = -atan2(r21, r22)

pos(4) = -PI / 2

pos(5) = 0

End If

Else

pos(3) = atan2(r21, r22)

pos(4) = PI / 2

pos(5) = 0

End If

get_position = pos

End Function

Function get_bodies(part As PartDoc, pbodies As Variant) As Variant

Dim cbodies As Variant, bod As Variant, bod1 As Variant

Dim vbodies() As Variant

Dim row As Integer

row = 0

Dim isnew As Boolean

Dim body As Body2

Dim body1 As Body2

cbodies = part.GetBodies2(0, False)

If Not IsEmpty(pbodies) Then

For Each bod In cbodies

isnew = True

Set body = bod

For Each bod1 In pbodies

Set body1 = bod1

If body.Name = body1.Name Then

isnew = False

End If

Next

If isnew = True Then

ReDim Preserve vbodies(row)

Set vbodies(row) = body

row = row + 1

End If

Next

Dim v As Variant

get_bodies = vbodies

Else

get_bodies = cbodies

End If

End Function

Sub select_bodies(bodies As Variant)

Dim seldata As SelectData

Dim bod As Variant

Dim body As Body2

Set seldata = selmgr.CreateSelectData

seldata.Mark = 1

swmodel.ClearSelection2 True

If Not IsEmpty(bodies) Then

For Each bod In bodies

Set body = bod

body.Select2 True, seldata

Next

End If

End Sub

Function atan2(Y As Double, X As Double) As Double

If X > 0 Then

atan2 = Atn(Y / X)

ElseIf X < 0 Then

atan2 = Sgn(Y) * (PI - Atn(Abs(Y / X)))

ElseIf Y = 0 Then

atan2 = 0

Else

atan2 = Sgn(Y) * PI / 2

End If

End Function

Function asin(X As Double) As Double

If Abs(X) = 1 Then

asin = X * PI / 2

Else

asin = Atn(X / Sqrt(1 - X * X))

End If

End Function

<< le code est dépourvu de la gestion des erreurs, à tester selon besoin, à modifier le chemin template, api 2022>>