Hello Stefbeno and Sylk.

As far as the design review is concerned, it will be more than important! and I am counting on the advice of the companies that will manufacture them, but only when we ourselves have defined as best as possible what we want.

Indeed, I didn't give you all the ins and outs of the whole thing or a specification because I didn't want to feel like I was giving you the baby and making you work, but just to benefit from your help.

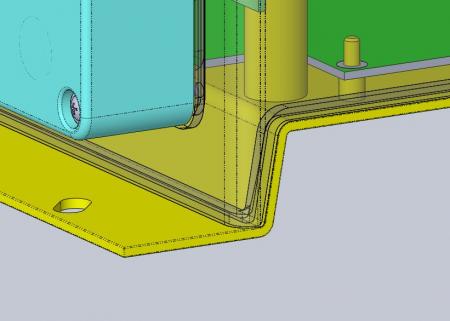

But to satisfy curiosity and have a more complete idea (which is normal when thinking about solutions), I attach the whole modeling (step) and also some explanations. The part we have been talking about since the beginning of this post is a "wall box bottom", on which electronic sub-assemblies are mounted and on "The now named: headboard" connectors are mounted. This part is then closed by a "Plastic Hood" to seal the whole. This hood has a second function which is the addition of options, but more than a lot of text, a glance will be more telling.

Due to a lack of information on my part, stefbeno's idea n°2 doesn't work, because on the part you know, the "font of the case" and the headboard can't be dissociated, on the other hand idea n°1 is rather interesting and seems to me to be well to exploit.

- The yellow piece is the one you know.

- The gray piece is the hood.

- The parts in blue are option boxes

- Fuchsia parts are shutters when the option boxes do not exist.

Maybe you will see some differences in modeling, especially on the joint, because I am sending you an earlier version of the step.

Bernard.

assboitier.step