Il y a un autre souci pour le moulage de ton oeuf.

Le motif doit être extrudé dans la direction du démoulage, il faut donc spécifier ton Axe2 en guise de direction d’ouverture dans les propriétés d’enroulement :

Pas bien :

Bien :

Il y a un autre souci pour le moulage de ton oeuf.

Le motif doit être extrudé dans la direction du démoulage, il faut donc spécifier ton Axe2 en guise de direction d’ouverture dans les propriétés d’enroulement :

Pas bien :

Bien :

Salut @sbadenis

C’était un peu pour ça que j’ai posté mon oeuf, pour gommer les maladresses de modélisations et lui donner une base propre sur laquelle il n’a plus qu’à faire un enroulement. Mais je suis d’accord avec le principe qu’il faut apprendre les bonnes habitudes de toutes façons.

PS: par contre c’est fun de pouvoir faire un sapin avec ![]()

J’ai corrigé, merci à tous

Bien vu Sylk pour la direction de démoulage

encore merci

Bonjour @criss

Cette partie pour faire le creux est-elle également sur un cylindre, ou sur un « tapis » à plat ?

Quelle épaisseur de coquille l’oeuf moulé doit-il avoir ?

Quel espacement entre les 2 moules ? (l’épaisseur de feuille à la sortie de presse)

Bonjour

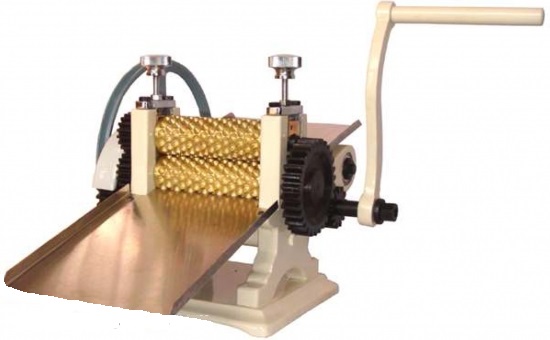

Il y a une synchronisation des 2 rouleaux pour faire des demi œuf creux la pate passe entre les 2 cylindres et ressort des demi coquille creuse

CREUX UNIQUEMENT demi œuf de 32.5 mm de haut AVEC le dessin carreau de ciment forme concave et convexe pour avoir une épaisseur de matière de 2 mm - Copie.SLDPRT (525,7 Ko)

demi œuf de 32.5 mm de haut AVEC le dessin carreau de ciment forme concave et convexe pour avoir une épaisseur de matière de 2 mm.SLDPRT (812,0 Ko)

GRAND OEUF a plat.SLDPRT (12,1 Mo)

GRAND OEUF FORME CONVEXE BOSSE a plat.SLDPRT (1,8 Mo)