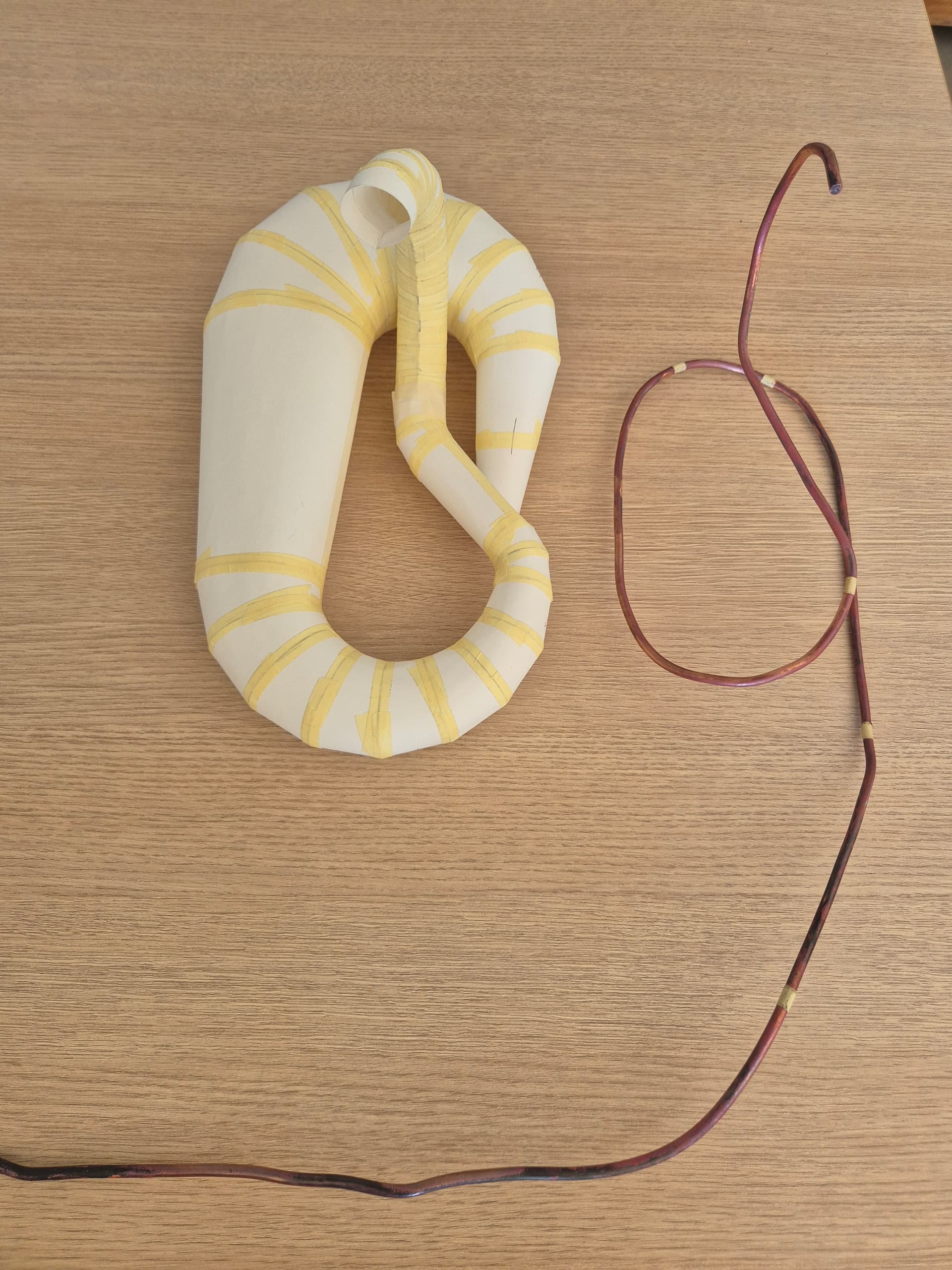

Hello, I would like to be assisted in designing in 3d my exhaust on solidworks student 2025 that I made in paper in order to refine the angles and sides, thank you very much for your feedback.

Hello Burt_Munoro,

For my prt, I would go through a 3D sketch with a spline, with the different sections desired.

For the moment I can't take screenshots, but as soon as I have my hand on my PC, I will.

…@+.

Good luck.

AR+.

Hello,

For my part, I will opt to actually start with a 3D spline and then make a succession of planes + sketches on each plane in order to be able to use the " Bossing/Smoothed Base" function with a different diameter on each plane

What is the final goal, to get a plan out of each sheet with the press or just to have a realistic 3d plan.

The starting bases will not be the same depending on the need.

I think it's a good exercise on SW and indeed if it's for shape optimization it will be an interesting step added to a 3D print.

Otherwise for the developed, since the mufflers are generally made with very thin sheet metal, the unfolded paper should be enough.

Hello

3D sketch, but I'll start with different straight lines to define the trajectory (relying on a spline why not). Using lines and endpoints I created plans and sketches defining the sections. And by thin sweeping I create the surfaces.

Hello @Burt_Munro ,

Is it for a scale model, a motorcycle (probably given the nickname... ![]() )?

)?

What scale, what dimensions? How is it made?

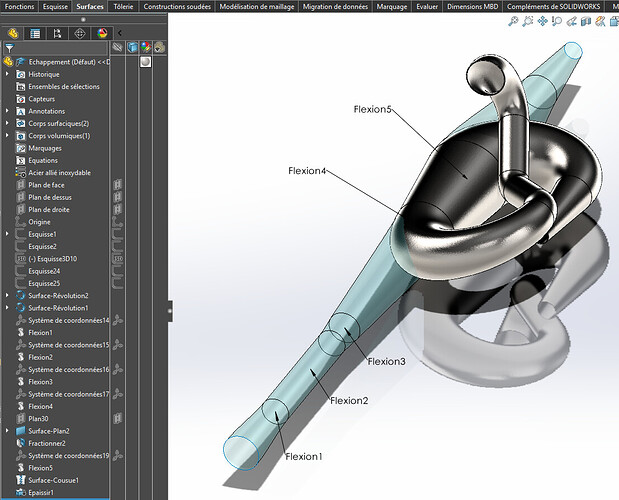

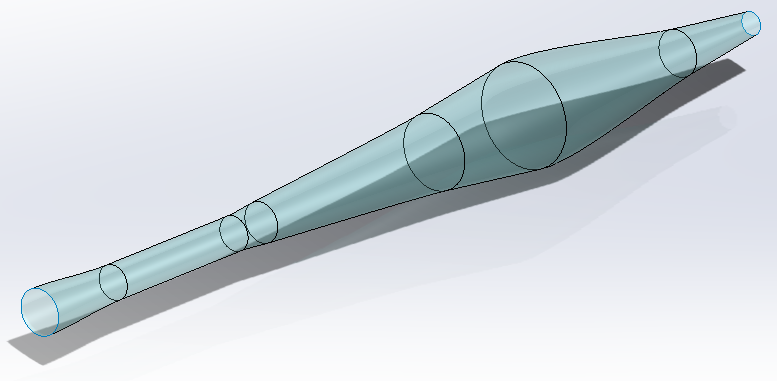

One possible way is to generate the surface of the pot in a "straight" version (see image below), and use the Solidworks Bending function to make the 5 bends...

The main problem will be to manage the angles.

In the end, less trouble than expected.

Even if the bending seen by Solidworks is not crystal clear.

It's a pity that the sketches don't follow the body in its deformation.

Result attached (SW 2022).

Escape.SLDPRT (2.2 MB)