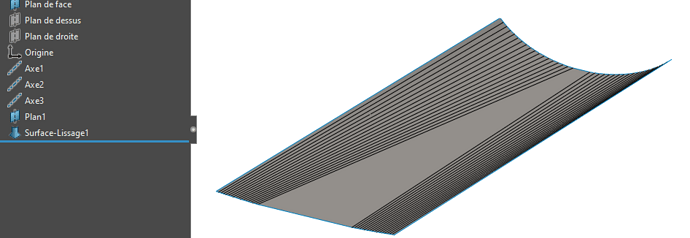

Hello, I can't develop this part in broken transition fold in 2mm sheet metal, sldws puts automatic notching by default, I'll attach it to you in surface if sometimes one of you can put this surface flat for me with the premium 2023 version?

Broken Test-3. SLDPRT (183.7 KB)

Hello;

Sorry I'm on Solidworks 2022... However, I find that there is a lot of " kink " for such a weak crunch. I think that removing one out of two (of folds) should largely solve your problem.

Subsidiary question: Do you use a folding table?

Kind regards.

1 Like

Hello @Maclane,

No, I don't use folding tables.

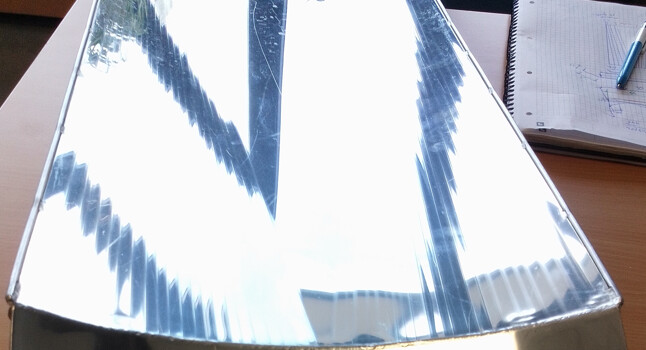

There are 34 folds on the prototype made by the boilermaker (made with a cardboard template) indeed I can test by removing a few folds.

Hello

I've had this little problem before.

In fact, you have to pay close attention to the value of the loss at the bend. Because for each bend, the angle changes and therefore the value of loss at the bend too...

Or switch to the K-factor, as a general rule it works well.

At home with our tools, I set K to 0 to have the inner surface as a reference and I have the bending axes laser engraved, then it's the talent of the bending machine that does the rest

Have a nice day.

2 Likes

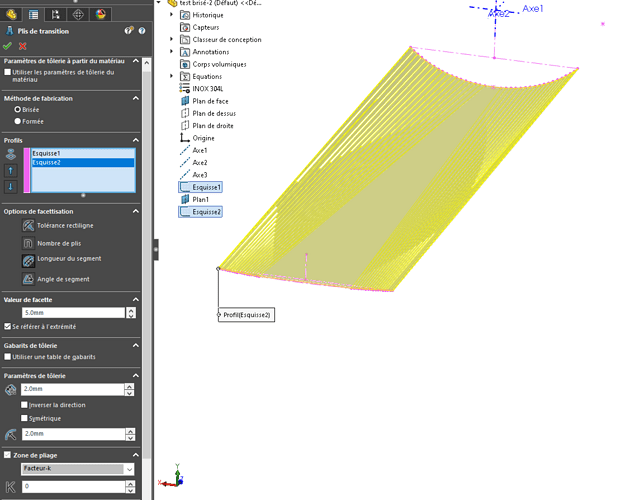

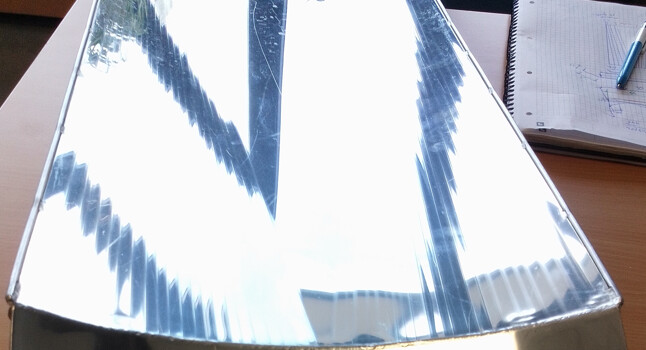

This is what I get in sheet metal, I tried to touch everything (in general that's what children do with the TV remote control and it works...  )

)

1 Like

Cool... All that remains is to validate @a.Eriaud's position as the " best answer "...

1 Like

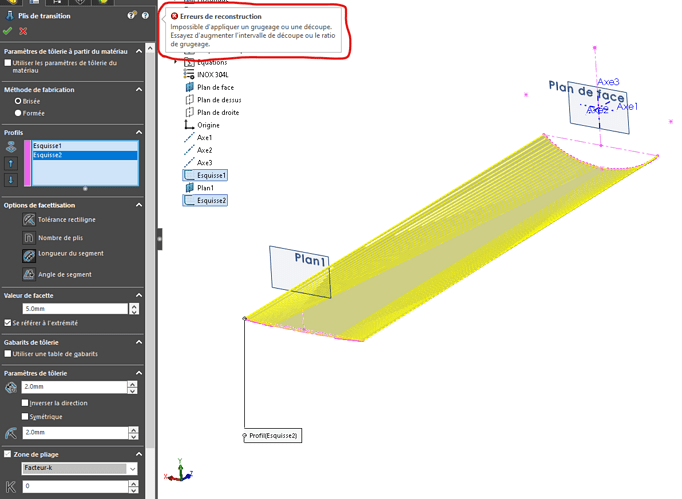

no it doesn't work, the white areas in the sight are chewing, and when I validate these settings the software doesn't want to take the part out... , I of course tried to play with these parameters but in vain.

For us, a k-factor of 0.5 for sheet metal between 0 and 3mm included, then a factor K= 0.33 for sheet metal greater than 3mm.

Avoid the segment length option (it often causes the function to bug) and favor the number of folds. In general, 12 to 24 folds max is already a lot and start with the minimum of folds if functional we can try to increase it (too many folds also mess up the piece regularly.

1 Like

I just had the same problem when drawing a roughly similar part.

Whereas by choosing the other manufacturing option (formed instead of broken) it works well, but without the bend lines.

If I have a little time this afternoon, I'll dig a little deeper...

Could you share your 3D (sketch only) with us?

That's nice, thanks for the help, here's the 3D with the sketches

Broken Test-2. SLDPRT (62.9 KB)

I also tried in form, it doesn't work either, and I need generators for the mep...

Well, where do I start...

- Your sketches are made on the basis of segments, which is not the most relevant for this type of function.

- I redrew the sketches with arcs, it's a little better. But it only works in " formed ", not in broken so for the bend lines it's dead! But I'll come back to that...

So I did some tests and I'm surprised by SW's reaction

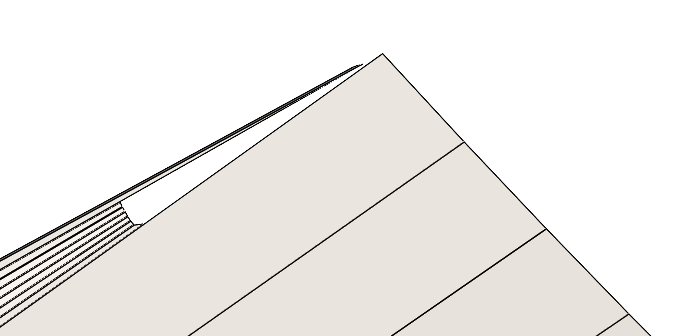

We should obtain this type of mesh:

(make a 3D sketch to wedge on your segments)

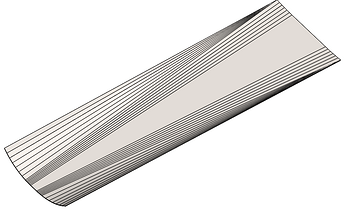

With my modified sketches (arc), I get this mesh:

" humor " I don't know what he took, but it must not be legal

" /humor "

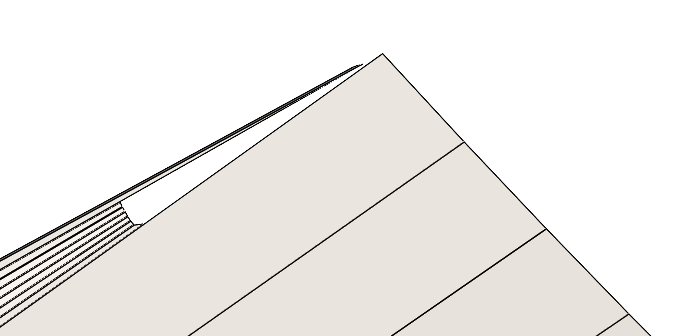

And with a nice hole:

No matter how much I turn the problem around, I don't see why SW reacts like this!

I have done hood wrapping several times (base 3 large segments + 2 small leaves and top with 3 small segments and 2 large leaves) and it has always worked well!

I'm trying one last thing to maybe help you out...

a+

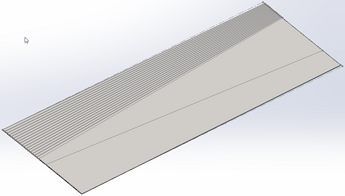

So, the only trick I found, a bit barbaric, is to draw the fold lines on the unfolded state:

Well, OK, it's ugly and it's a hack considering what SW is supposed to know how to do...

I am attaching the file to you, I hope you can open it. I'm in 2024 and tried recording in 2023, it's new so... " no comment "

Broken Test-2-V2023. SLDPRT (219.5 KB)

I don't know why, but sometimes I miss my drawing table

3 Likes

Impecc it works, it helps me, indeed you have to take out the toolbox, between the formed and the broken the loss at the fold will be different but here I nitpick  , a BIG THANK YOU!!

, a BIG THANK YOU!!