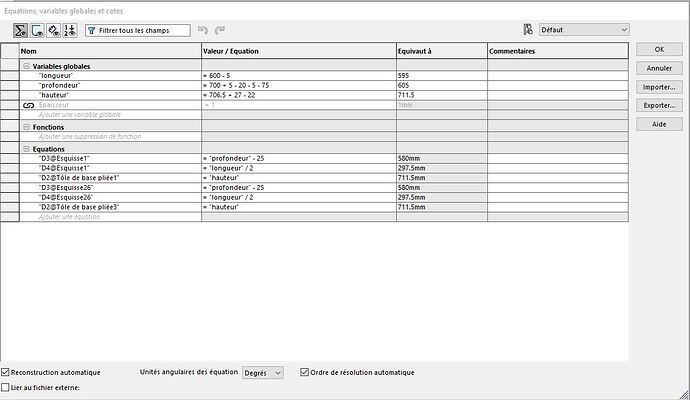

Hi all. I'll explain the situation to you: we draw in multi-body (sheet metal). And since we make custom kitchens, I created equations, so the next time I have the same piece of furniture, I'll do a " pack and go ", modify the equations and everything will follow.

Now, I thought it would be better to draw in assemblies (the top-down method), but I don't know how to create equations in cases like this. Should they be created in every room?

Hello

The problem with this kind of design is the fact that the part is controlled by the assembly. Depending on the way your company works, this can cause problems.

If you are really working on the project: all parts start with a unique project number that you change in case of copy/repeat, you can use external references (your parts will look for information in the assembly). With us we use a pilot sketch in the assembly: this can allow you to go directly to get planes/points... rather than going through equations in the rooms. In the end it's very simple to use and quite practical.

If there is a risk that a part of project A will be used on project B without changing its name, you should not use the above method (risk of modifying a part on project a which would impact project B)

Hello

The next step in automating your tasks is to use PilotAssembly from the myCADtools tool suite, or DriveWorks, which must fully match your studies

Personally, I advise you to set up a skeleton/envelope.

Very well explained in this video: Setup, Skeleton and Envelope - YouTube