Hello everyone, I have to fix railing plates, " English " mounting in a concrete slab, I have several bells from the workshop, some say plastic pegged lag screws, other dowels to hit or even chemical pegs... In short, in order to clarify this subject and to get everyone to agree, will any of you have a standard to share with me please?

There is probably a DTU, the key is to find it:

As a first approach, I will look at the resistance, so rather the dowel to be hit (solid support) or chemical (hollow support).

The stress test is at the top of the railing. Effort to be transmitted to your ankles for verification.

Example of a morocco standard project (based on an identical European standard):

https://www.imanor.gov.ma/wp-content/uploads/2020/06/10.8.859.pdf

Bjr,

with us we use HSA anchors, being careful to be at least 100mm from the edge to avoid bursting.

hello @M-Scofield

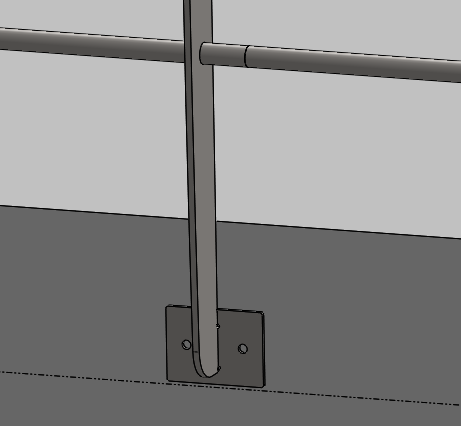

With seriousness in my heart, here is my experience on the subject. ![]()

The most important thing in these cases is the quality of the support (cracked or not for example).

Afterwards, to make your choice without getting caught up with standards, it is better to use the manufacturers' certified calculation tools as well as the software they offer.

I worked with SPIT (you have HILTI which offers the same services)

https://www.spitpaslode.fr/fr/Fixations-lourdes-et-moyennes_fFR_179974.htm

https://www.spitpaslode.fr/fr/logiciels/logiciel-de-dimensionnement-i-expert/

From memory with the software you can put different pegs if on the same place if you have different supports to test and choose the most suitable system.

Hello

Personally, I use this free application to size the fasteners of small metal structures.

https://profix.wurth.fr/fr/wurth_profix/telechargements/logiciels_1/logiciels.php

It gives an idea of the fasteners to use and it allows you to check and size your anchors.

These are more or less the same tools offered by SPIT mentioned by Zozo_mp

Nice indeed the wurth app!

And generally, as the results of the app show, it's not the ankle but the support (good quality concrete) and the structure that takes the most important stress, an ankle resists big stresses.

Hello

I agree with Zozo_mp on this subject regarding the choice of bindings. Personally, I will see more of a " diagonal " drilling of the frames for better resistance.

Kind regards.

With us minimum distance from the edge 80mm.

And for the dowels, it's HAS-U type with Hilti resin chemical sealing (a threaded rod cut at a bevel does the trick and it's cheaper). ![]()