Hello

After 15 years of special machinery, I switched to the light metal structure.

SW is not the most suitable software for this field, so I am looking for help to gain speed and efficiency in the design of my models and the creation of my plans.

After following and inquiring about different training courses, I realized that I needed personalized support from those who are used to metal structures.

This support will of course be paid.

Thank you in advance for your help.

Stéphane

Hello stephane.roquier,

I'm coming to the subject, the builder of our building uses this one => Tekla Structures – BIM software for structures | Tekla

It seems to be not too bad and quite complete in terms of file types, to see.

Good luck.

@+.

AR

Hello AR,

I inquired about Tekla which would indeed be more suitable.

Only this would require a new license, training(s), time to get to grips with it... Which would be a lot of financial and personal investment, and I can't afford it at the moment.

Thank you for your feedback.

Stéphane

Hello again stéphane.roquier,

There has been the possibility of doing structure for a few versions, I had forgotten about it, it looks good.

To see =>https://www.solidworks.com/fr/media/solidworks-2023-sheet-metal-and-structures

also this since 2020 => https://www.solidworks.com/fr/media/whats-new-solidworks-2020-structure-system

@+.

AR.

Yes, Visiativ had shown me these features, but I found it very limited at the time. I'm going to find out about the 2023 version which looks more evolved.

Thank you!

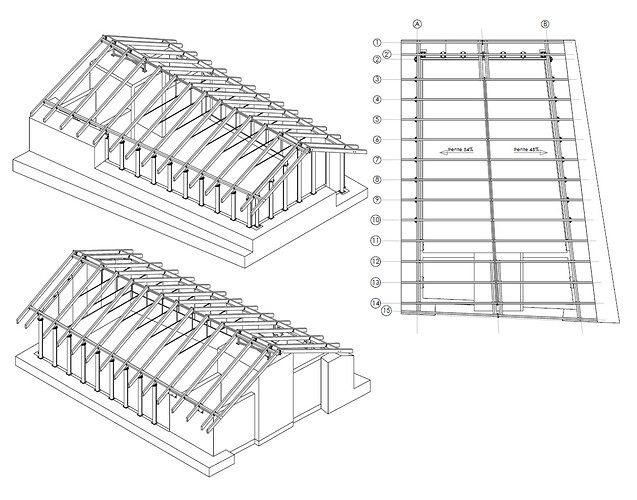

Notice to carpenters: what would be the best method to design this type of framework? Many elements are similar without being quite identical (configurations, family of rooms, etc.). Knowing that you have to get out plans, speed,...

Thank you!!

Otherwise there is this kind of module (not tested and unknown before research):

https://www.thesteeldetailer.com

It may be worth it even if with this module it may be more functional for carpentry but we retain some heaviness of SW unlike a Teckla style software made for carpentry.

Yes, there is also SolidSteel, but it is an additional module to buy.

Yes, a module in general is paid, then you have to see the cost and time saving ratio.

If it costs 4000€ and after 2 deals it is reimbursed because you have saved a hundred hours, then the investment is worth it.

Maybe contact them for demo version.

I contacted them, I have the docs and the prices. The module is in English. And I'm a new small business that can't yet amortize an investment in 2 deals ![]()

Hello;

We shouldn't neglect the Solidworks tutorials (for once the software tutorials are rather well done...).

For a framework as represented above, I will start by creating all my families of parts to be used with the " mechanically welded " function

(*.sldlfp) that I would save in a location other than the original one from Solidworks.

https://help.solidworks.com/2020/french/SolidWorks/sldworks/t_Weldments_Creating_a_Custom_Profile.htm

(In this case, you should remember to change the location in the Solidworks options.)

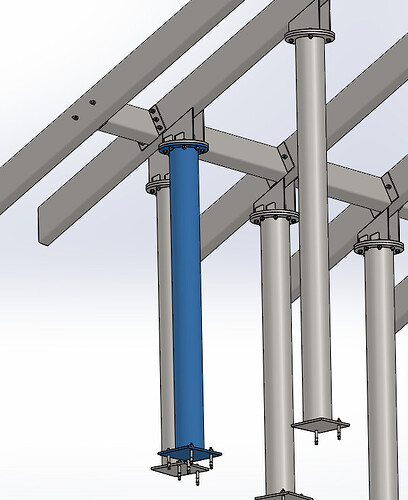

And since I prefer to work with assemblies, for vertical beams, I will generate as many as supports of different sizes.

Then a mechanically welded plan for the " roof " beams (I don't have the technical terms of the profession).

…

But it is very likely that you will end up with as many different answers as there are cartoonists... Everyone has their own method. All that's left to do is find yours.

Kind regards.

Hello

I regularly use the tutorials and fortunately they are there.

I don't use the families of pieces yet, but unanimously I have to get started...

As for the different methods, the information collected on this forum will help me to refine mine.

Thank you!

Personally, I make the main framework in the same multi-body room.

This allows me to have a list of welded parts that is consistent and updates quickly.

Then all the equipment such as smooth, cladding, roofing, I do them in separate rooms and then a general assembly.

Thank you Ronathan, this is what I have been trying to do recently and it is indeed an interesting method and the best for the parts list. But not always very practical for drawing (selection of bodies). Moreover, is there a way to ' isolate' › ›, ' ' assemble ' › welded elements in a multi-body part, to make them bodies? Example: 1 body that would be called ' post ' and which would include tube+plates+gussets, but without extracting it from the part. I don't know if I'm very clear...

And then the import in the room mode is not great.

Hello STRO,

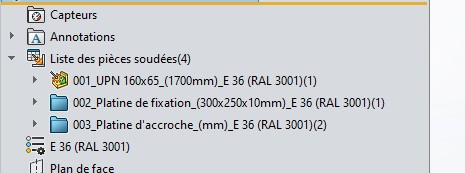

Yes it's possible by going through the list of souées parts, for the MEP, it's the same it takes up the bodies well.

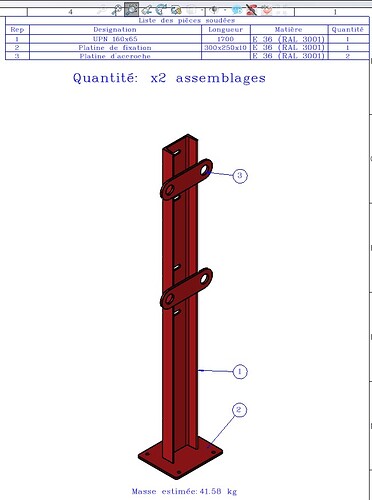

Here is a picture =>

There you go, good luck.

@+.

AR.

Hello AR,

Thank you for your feedback, but I did express myself badly.

Going back to my example of a framework and if I made it in a single multi-body piece, would it be possible to group bodies? For example on my image, group the tube and the 2 frames (in blue), and name them post 1.

For me, multi-body should only be used for welded elements, otherwise you have to go through assembly.

In the case you are explaining, we have an asm made up of columns (one tube and 2 plates = 1 multi-body prt), crossbeams ditto (rectangular tube + plates), spars (rectangular tube + sheets + interfaces with columns) and screws.

Doing everything in one piece will be unbearable, if you can do it...

The big question about the families of parts/configurations: it is to determine the recurrent standard parts, the parts topologically close but specific to each case (so maybe to put in a part model).

The question of tracking over time is important: if you update a library part, how will the old designs behave? It may be necessary to consider an export (pack'n go) of the deal once it is finished for the freeze in time.

Hello STRO,

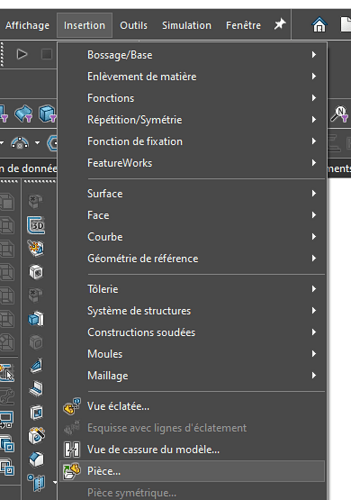

If I understood the question correctly, can you insert an existing turntable into a .prt file? Technically it's possible, by doing " insert > piece " in the part, but it will quickly become a spaghetti dish and as the saying @stefbeno if you modify this turntable later, your old conceptions will go to waste, this method is to be used sparingly and knowingly. ![]()

Hello STRO,

Yes it is possible, but I advise you not to do it, it is better to redesign it, as a welded part.

Like for example for your beam with its plates, like on your screenshot or just like my C-joint capture just before.

There you go.

Good luck.

AR.