Thank you @ac_cobra_427 for your quick answer but it seems to me that you can't have the tips in laser tube when the laser navigates around the tube.

It depends on the capacity of the laser, you have to see this directly with your laserist. Some also add nesting to adjust the quick positioning and justify the choice of the tube laser. However, the 3d drawings remain normal with us and it is the laserist who manages with the step sent.

Thank you @sbadenis for your answer. Indeed the laserist manages and the step or iges of the part as sent in my post is enough for him but it's for me to have the most representative part because I have elements that will come to weld on it.

Yes @ac_cobra_427 I had seen this video ![]() and with the radius of the tube we must have a certain cut in the shape of a bead with angled cuts.

and with the radius of the tube we must have a certain cut in the shape of a bead with angled cuts.

The interest of the tube laser for me is to let it manage the cutting nesting phase or ideally cut area for bending:

For me there is no real interest in having a real representation, welding will do the rest as we often say in the trade!

At the beginning we also wondered about the realistic drawing but if you change the laser the method can also change for a final result which will be identical once soldered.

Hello

Your tube is only guilty by a 5-axis machine (or 4 maybe).

If the machine does not have an angle adjustment, the laser will always be perpendicular to the axis of the tube (and so you will have to choose the edge you want to keep: inside or outside)

Here's roughly what it looks like in real life.

Be careful, you have to think about deducting a tube thickness because the dot no longer exists!

Good evening

Nice cutout.

What are the functions to achieve this result??

Hello

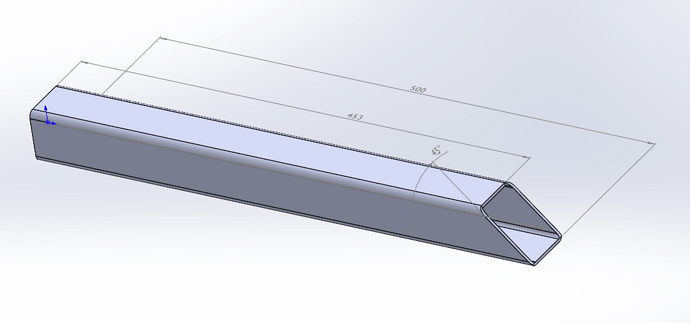

Attached for example of a tutorial piece I made a few years ago for tube laser cutting

tubular frame 30x30x2 in sheet metal.sldprt (317.0 Kb)

tu 30x30x3 sheet metal a135deg.sldprt (186.7 KB)

Thank you @ac_cobra_427

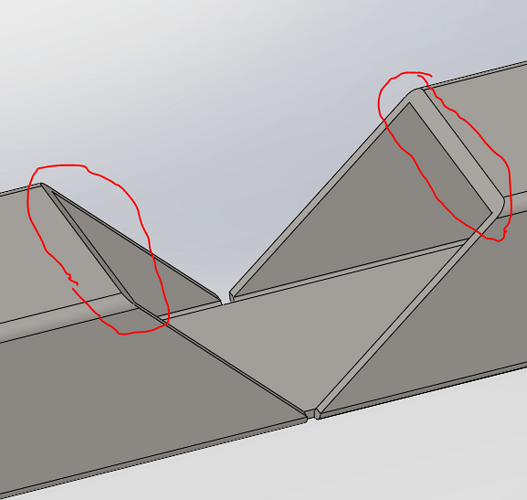

But what @ronathan is actually realistic in the upper part (for a 3-axis laser) where you are not (because the cut is not normal to the axis of the tube):

That's why I asked him the question. This high shape is easily done if the tube is made of sheet metal (there is a question about this at the moment by the way) but not if it is extruded (with mechanically welded or extrusion function).

It must be playable with a material removal by sweeping but a bit sharp to implement I think.

For my part; It's the tube that moves so the cut would be like these since the cutting head is on this face. The reasoning in relation to the axis is correct for a Tu in Ø which by default does not have a flat surface but in the case of a square or rectangular tube the cutting head perpendicular to the face so cuts like your part.

For the example I made a simple top cut but to be more in reality it would be necessary to do a swept material removal using the 45° cut as a trajectory

Hello everyone and thank you for your answers. Here is the laserist's step that I would like to make with the functions that go well, in my opinion I have to tinker with surface. Thank you for your help ![]()

1125-015.STEP (136.2 KB)

If some manage to get the result of the step I sent, I'm interested ![]()

Here's what is feasible under version2023 but I find complicated for what it is ![]()

Laser tube. SLDPRT (161.3 KB)

attached, I don't see what @ronathan did because at home I am 2016 but here is the part made according to your STEP file

1125-015 AC COBRA 427.SLDPRT (149.2 KB)

Thank you @ronathan but I can't open it being before 2023.

Thank you @ac_cobra_427 it's perfect that I used to complicate my life on the surface!! I switch to mechanical welding for my tube lasers and not to sheet metal but I think it should stick by using your method.

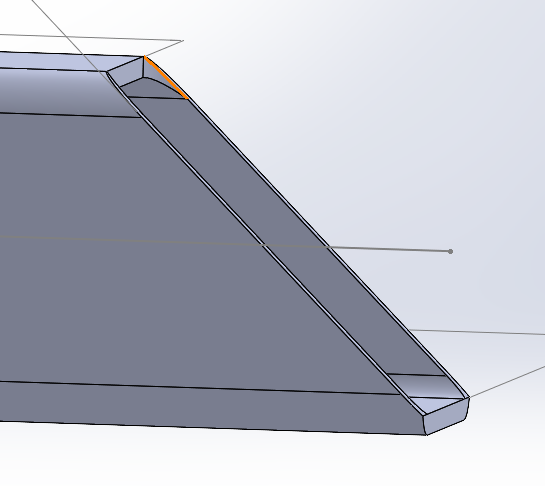

Nickel but I do almost everything in sheet metal work because it is simpler and closer to reality but after that everyone has their own method to get there ![]()

![]()

The technique of going to sheet metal is tempting because it is automatic via "normal material removal" but not necessarily simpler to finally produce a flow list because it is not considered a mechanically welded profile.

Even if in conclusion I still don't find the point of this maneuver which will end up being time-consuming in the end.