@ bart it could maybe solve your problem

Datakit's new IFC reading enables...

Datakit's new IFC reading enables interoperability between BIM and CAD

03 January 2017 by Datakit

Datakit, a company specializing in CAD data exchange, unveils its brand new interface : a library for reading the IFC (Industry Foundation Classes) format, the standard exchange format in the field of BIM (Building Information Modeling).

" With this new interface, Datakit is breaking down the barriers that may have existed between the BIM and CAD worlds," explains Samad Elboustini, CTO of Datakit, " Indeed, CAD software users may have to work with IFC files from BIM software (such as REVIT,™ ArchiCAD,™ Allplan™, SketchUp™, Vectorworks™, etc.), but cannot use them if their CAD software cannot read them.

By adding an IFC format read to our standalone CrossManager converter, we give users the ability to convert .ifc and .ifcxml files into the many CAD formats we know how to write. After conversion, these files can therefore be opened in most CAD or visualization software."

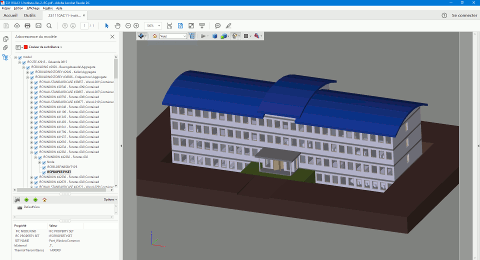

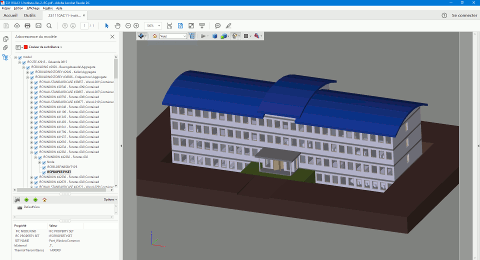

IFC file converted to 3D PDF with CrossManager. This allows the file to be opened in Adobe Acrobat Reader™ for viewing. The model tree and properties are also converted.

IFC template provided by Architect Building Designer Office (Cc-by-3.0 license)

Software vendors can also take advantage of this new interfaceto provide their users with interoperability with the IFC format.

This is possible thanks to CrossCad/Ware : An SDK that can be integrated into third-party software. By integrating CrossCad/Ware into their application, software vendors take advantage of Datakit's technology, allowing them to access data in the IFC format. This allows them to read the geometric data, as well as the model tree and metadata contained in this format. API integration is simple and is completely transparent to end users.

This tool is dedicated to BIM software publishers , as their users need the software to be able to read the standard format of their field. But it is also intended for software vendors in any other field wishing to offer their users the possibility of importing BIM data.

Many vendors already trust the robustness of CrossCad/Ware. Indeed, already more than a hundred software programs in different fields (CAM, ERP, PLM, visualization, simulation, calculation, metrology, BIM, etc.) are based on Datakit's technology for reading 3D data.

To test IFC file conversion with CrossManager or for more information on software integration possibilities, visit datakit.com, or contact Datakit at +33 478 396 369.

@+ ;-)