Hello

I can't seem to flatten the uncovered stringer, simply the rounded part seen from above and seen from the front.

Thanks in advance to whoever manages to do it (a beer is negotiable:))

Kind regards

assembly1.sldasm

Hello

I can't seem to flatten the uncovered stringer, simply the rounded part seen from above and seen from the front.

Thanks in advance to whoever manages to do it (a beer is negotiable:))

Kind regards

Hello

Sheet metal part or surface/volume model?

The problem of flattening is not the same depending on the mode of creation...

Providing only the assembly file is of no use in identifying your problem.

It is the file of the piece of the stringer that must be sent to us.

For my part, future version impossible to open it unless you have a step or xt format.

A screenshot can also be helpful

https://www.lynkoa.com/de/contenu/r%C3%A9aliser-une-spire-pour-vis-darchim%C3%A8de-en-t%C3%B4lerie-0

Look at the tutorial above valid for a coil as on the example, but also for a stringer by drawing the 3d sketch with the top of the stringer and the bottom of the stringer afterwards.

I had an example but I couldn't get my hands on it.

And also no need to create 50 positions, we won't respond faster, we are all volunteers!

Hello

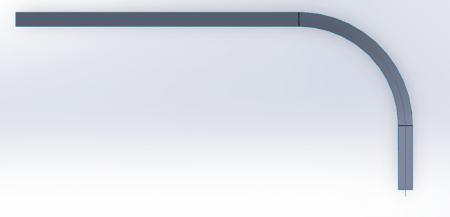

Based on the tutorial offered by @sbadenis, it is quite simple to generate the stringer in the form of sheet metal parts. Each side can be flattened in the classic way.

The attached model uses this principle (SW 2021).

Notes on the creation of the silt:

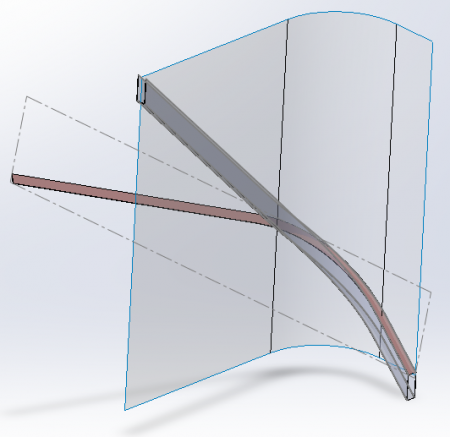

In your initial model, the base surface is generated by smoothing the rectangular section along a 3D path. This feature does not keep the generators vertical in the area of the turn, causing "blisters" (image 1).

I used the smoothing principle but generating the faces one by one. The result is perfect (image 2).

It is on this corrected surface base that I created the sheet metal part.

As these are the first functions of the staircase, it made a mess in the rest of the creation of the supports and steps.

You will be forced to retake this whole part.

A tip in this regard: avoid alternating the functions of the boilermaker (supports) and the carpenter (steps), the structure of the building shaft will be clearer. Especially if you don't uncheck the "Merge result" box. Welding an oak step on its steel support remains a technique to be developed. Silt, supports and steps should be disjointed bodies...

Kind regards

Thank you very much Mr.BLT for taking the time to answer me

The answer was very useful to me

Kind regards.

Thank you @m.blt for taking the time to make the play. For my part, I was a little taken and it wasn't possible but yes the principle is that.