Hello

I work on powder process implementations (bigger and bigger).

I integrate purchased machines and machines that my colleagues make. I create the pipes and access platforms.

I work in networks (it is difficult to do otherwise, because I do not work alone on projects).

I manage to optimize my 3D models by creating sub-assemblies and working by sub-assemblies.

I make sub-assemblies by room or in each sub-assembly, I have my building which allows me to have a main sub-assembly without constraints fixed with the buildings.

For the piping, I make a subset and I create axes and planes for my pipe inputs-outputs (such as the publications under catia).

My problem is the general drawings. I spend my time waiting for solidworks.

My plans are between 10 and 20 pages long with a maximum of 2 views (usually sections of the building).

Sometimes I have to make 1 file per page. (some files reach 1 GB)

My times:

- Recorded (5 to 20min)

- Make a cut (5 to 10min)

- Open the drawing (5 to 20min)

- Sometimes a zoom takes me 5min

- Making a file/save as (just to get the windows page) takes 5 to 30 min

- Make a dwg (5 to 30min)

- Make 2 clicks: 3min

The drawings take me about 3 days (with nights of waiting) instead of a day.

The modifications are also complicated to make.

I can't afford to record often because it's long, so when it crashes we start again.

Do you know of solutions to optimize the layout of complex research? Additional modules?

The speed pack is too complicated to set up and it bugs the drawings. I open the model in light, I don't see any improvement.

Thank you in advance for your feedback.

Hello

To lighten the whole thing, you would have to activate the blocking bars on all your parts and assemblies and sub-assemblies. This avoids unnecessary reconstructions. Attached is a macro that @OBI_WAN had shared and that launches from the assembly and blocks all the parts in reconstruction.

freeze Ac cobra.zip (29.3 KB)

To enable the Block Bar, click Tools > Options > System Options > General and select Enable Block Bar . Block functions: Move the pointer over the blocking bar.

3 Likes

Hello

You have to see everything SW offers to lighten all this: display states, speedpacks, management of large assemblies...

There is certainly not only one lever to use to achieve something more fluid.

Doing a SW training dedicated to this kind of problem should be able to help you (what is 3 days of training compared to your waiting times??)

Since you are working on a stack of sub-assemblies that seem very heavy, replacing them with a part file containing only the interfaces (and possibly the external view in speedpack) should help a lot (you will waste time creating each part file and then maintaining them according to the revisions, but surely save time on the final MEP).

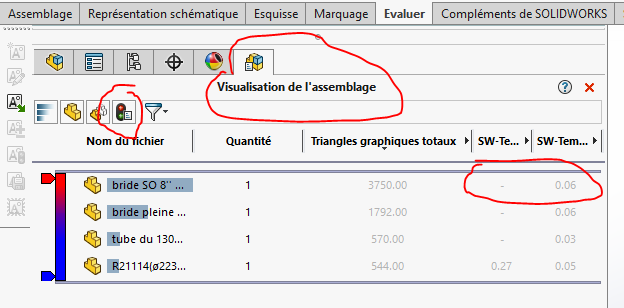

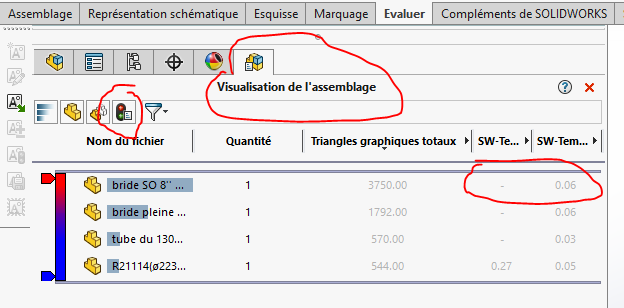

SW's assembly analysis tools are also very useful (assembly evaluation/visualization tool):

You may realize that having 200 occurrences of a small commercial fitting with the logo engraved in 3d on it does a lot of calculation. A visit to your library to remove these useless and heavy details will surely be very beneficial). The same goes for models that are too detailed on your screws...

1 Like

Do I understand correctly: the building appears in each subset?

So when you view the full set, the building appears multiple times in overlay.

If this is the case, you must make 2 configurations in your S/E: default (without building) / with building.

This could already lighten things.

Thank you for this macro, I think it's very interesting.

I agree with you

I try to transform the sets bought by shares.

After colleagues' machines, I think it's complicated, because we need to see the impact of changing them easily.

For training, if you have formats, we may be interested. We are an office of 20 people, 4 of whom are in location.

Personally, I'm not a fan of configurations, they tend to make the model lag when you switch pages. And according to the research on SolidWorks optimizations it is not the best.

To avoid having several buildings, I hide them. Generally, buildings are not too greedy, I make the interesting walls and then I set up the model in a point cloud to check for collisions.

You can change your asm to prt by doing like these so the prt keeps a link with the assembly in case of modification, you will just have to do a ctrl-q to update the part.

1 Like

Another solution is to check under which version of SW are the plan template if you are in SW2022 and the plan template dates from 2004, transformed into in 2005-2006... we must consider doing it again.

This is what we have done successfully (loading/recording time divided by 2 or 3)

To check you can use this macro in VBA:

'------------------------------------------------

' Preconditions:

' 1. Open a model document.

' 2. Open the Immediate window.

'

' Postconditions:

' 1. Gets the version number of the model document.

' 2. Examine the Immediate window.

'------------------------------------------------

Option Explicit

Sub main()

Dim swApp As SldWorks.SldWorks

Dim swModel As SldWorks.ModelDoc2

Dim vVerStr As Variant

Dim i As Long

Set swApp = Application.SldWorks

Set swModel = swApp.ActiveDoc

Debug.Print "File = " & swModel.GetPathName

If IsEmpty(vVerStr) Then

vVerStr = swApp.VersionHistory(swModel.GetPathName)

End If

If Not IsEmpty(vVerStr) Then

For i = 0 To UBound(vVerStr)

MsgBox " " & vVerStr(i)

Next i

Else

Debug.Print " No version information."

End If

End Sub

2 Likes

Hello

I don't know which version of solidworks you are on.

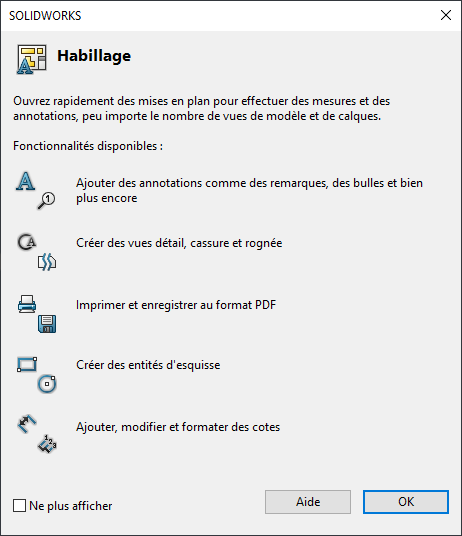

But with the 2021 you have the opening of the plans in DRESS UP mode.

This allows you to open your plans without changes, but you're limited in the functions you can use.

Here's what you can do in this mode.

A+

1 Like

Hello, very vast subject.

What you live is my daily life.

I'm not going to be able to help you much because your problem can come from 1000 reasons believe me I know what I'm talking about.

The way you draw already has an importance on latency.

The points you can fix quickly are.

1-effectively the macro thank you @ac_cobra_427

2- Cleaning up imported parts is to be banned, redesign them in a succinct way.

3- No surface area and hunt for open surfaces.

4-Hunt for reconstruction times to limit small details as much as possible

5-remove unnecessary things (e.g. screws in the frames)

6- Hunt for triangle graphs, you need less circular things, my bodyguards are octagonal.

7-To make your plans, open your assembly in resolved.

8-On your plans hide the views you don't work on.

9-Think about the detached drawing can help.

10-Defeature your sub-assemblies.

11-Beware of hidden pieces which can sometimes be misleading.

12-Unload hidden components.

Here is something to check at the moment t because as I told you a big assembly is already starting to be managed at the first line you make because after that it's too late.

May the force be with you (you're going to need it)

7 Likes

Hello

I am revisiting the subject.

We had another problem. We use point clouds for industrial buildings with a leica scanner. The SolidWorks add-on from Leica is no longer marketed (Dassault no longer wants to sell their license).

So we asked for advice from Dassault and they suggested that we add the 3dexperience plant layout design software.

Do you know this software?

I can't find too much information on the internet.

We don't want to use a PDM as a 3D enovia experience (too much constraint and too big a project to launch), but they tell us that we don't have to.

Did you know if it is possible to make site plans?

Yes, site plans are possible.

Depending on the level of detail required (coarse, medium, refined, etc.), the opening of the MEP is more or less long.

For cross-sectional views it seems to me that it is also possible.

If I understood correctly, it's the Catia graphics engine behind the software, so in theory what is possible in Catia's drawings must also be possible.

But on the other hand, it is indeed difficult to find videos on the subject (especially the drawing part)

During the demo of Visitativ a demo of this part was launched but impossible to find it online. (maybe ask them for the link or send it to you)

1 Like