Hello

First of all, I'm in SW2021.

I have a part that contains derivative parts, in this case a specific piping element with derived parts collars and flanges.

In the drawing of this part, is it possible to create a BOM that contains the list of these derivative parts?

Thank you.

I don't think so, because the imported part becomes a function.

Why not create an assembly?

For me the parts are easier to import, moved, a bill of materials is possible and if necessary function to add a virtual part (or not) does the trick.

Hello

If you have Solidworks PDM, it seems possible: SOLIDWORKS PDM 2021 Displaying derivative part references (javelin-tech.com)

It's possible, it just has to be that the bodies are not merged.

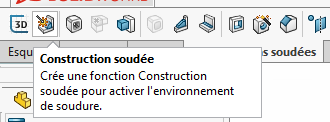

The ideal is even to go through the " welded construction" environment (just click on this icon:

).

).

You can then make a list of welded parts.

@sbadenis : this is a fairly common way of doing things in piping, it avoids creating a prt file for each piece of tube, while taking advantage of a library of standard elements (flanges, taps, etc.).

@stefbeno for the piping for me, assembly with the flanges, elbows and a virtual part (or not for flow) with all the tubes in construction welded.

I find it faster and cleaner. But happy to learn another method!

I'm more in favor of creating an assembly too.

From memory, the elements of a welded part list prefer to use the " Description " property, whereas with an assembly it is more generally " Designation " in the BOMs.

This is likely to be ambiguous.

Hello

Thank you for your answers,.

It's a part that I recovered that was made by an intern, the goal was not to have to reassemble it.

Well I think I'm not going to cut it, because nothing comes close to what I have in my assemblies in terms of nomenclature (while the personal properties are the same)

In any case, thank you for your responsiveness, proof is made that it is better to go through an assembly.

Have a nice day.

It all depends on your need @pascal.babel . I frequently use the derivative part ... but it's sure that I don't need a BOM afterwards. It's more for parts with custom machining ![]()