Hello

My colleague and I are wondering about the applicable standard for sizing this part under study.

It is a jack that is used to lift a wagon (a bit like a bridge in car garages). Here we would have 4 of them to lift the wagon.

We contacted Apave which gave us the following 2004 decree as a link:

https://www.legifrance.gouv.fr/loda/id/JORFTEXT000000439029

However, it seems that this is a stop for verification during a restart, and not for sizing.

If you have an idea of what is applicable, it would give us a foot in the stirrup to go deeper into it.

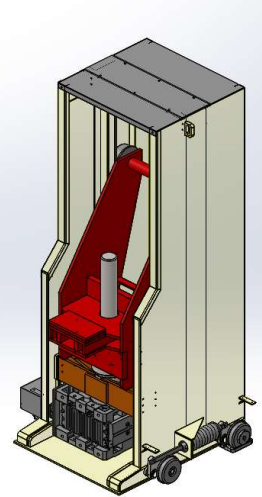

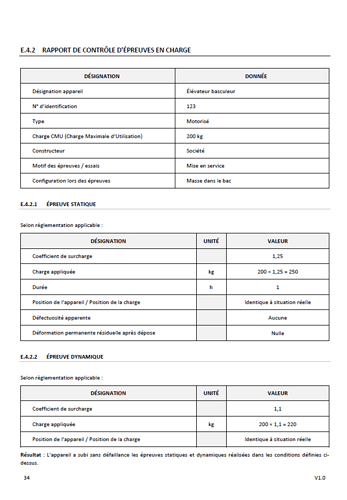

For the operation of the assembly, the wagon rests on the red part, which translates vertically thanks to a motorized worm screw.

Looking forward to reading you

Love and chocolate to all

I would be tempted to first go for the machine directive (https://www.eic2.com/pdf/securite_machine_ed807.pdf).

What is the vertical stroke?

Is an operator required, in a normal situation, to go under load?

Is the access under load protected to prevent the operator from accessing it?

I don't know to what extent the classic standards for lifting devices can be applied: a priori, there is no displacement of the load.

You cite the example of the automotive bridge, which is perhaps the right way to know which standard is applied. Knowing that with the car bridge, we are in the case of the foreseeable parking of a person under the load, so certainly a big increase in the safety coef.

Yes my apologies I had not specified.

1200mm stroke, an operator will have to work under the load, no protection for access.

I will take a look at this document in that case.

Thank you

And certainly a blockage of the cylinder in the up position, it must not be that if a hose (hydraulic?) lets go down by itself.

But the lifting standard is indeed imposed for any lifting of a load (straight or not), even if it is added to other standards (machine, etc.).

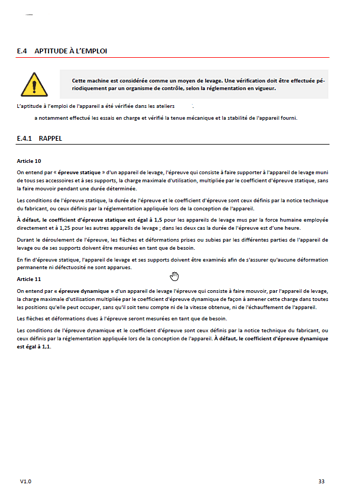

There will therefore be a static and dynamic load test to be carried out.

To be transparent, this is a piece of equipment that has already been present since the 70s, the customer wants to increase the load by modifying the existing one as little as possible.

The calculation notes of the time only take into account the non-reversibility of the screw for the maintenance. But it is impossible to draw inspiration from it to find any standard referring to it.

As a result, I do think that drawing inspiration from the standard applicable to lifts is a good way forward: NF EN 1493: Vehicle lifts (Please note that there was an update in 11/2022).

On the other hand, I don't know what a change of capacity on such a device implies because it is the modification of an essential characteristic of the device.

Will it be considered a new device or not?

Good evening

Apart from the very relevant remarks and suggestions of our colleagues, there may be another way of looking at the problem.

I may not have read it well but is it a hydraulic or electric cylinder (four in number) as is done on a machine dating back 50 years having undergone or not successive transformations (or even tinkering) and undocumented. And we don't know how many overloads or misuses it has suffered.

I'm going for it!

It all depends on what is changed!

Let's take two cases: only the cylinder is changed. In this case, the supplier's solidity standards and guarantees are sufficient, provided that the building supports the new total load.

Secondly, the frame is modified, in which case only the calculations will tell if the additional load is compatible with the new forces.

@stefbeno will tell you better than I can that in the norm not all the paragraphs apply in your case.

The sizing must above all correspond to the rules of the art of mechanical construction and safety and it is from the solution chosen and the results of the various and varied calculations that we see before moving on to the standard (which are not always incredibly precise in detail).

Of course, you can read the standard before you can proceed with the sizing because if the standard specifies a minimum of 8 for your case, it is better to integrate it right away.

Obviously, what I say will provoke reactions but I have the impression that the problem is above all, the modifiability of the old model or not to begin with.

I have only had to modify old machines three times and it has always been a hassle and prices that have greatly inflated, because they are real boxes of surprises with a lot of problems of size and resistance of old materials.

Boxes of surprises, like the well-known pandora's and so I run away from them like oil crankcase!

Kind regards

2 Likes

Very good question...

While strolling around the website of our standards retailer, we also came across the 1494+A1, relating to "lifting jacks" (which can be used by several people at several points). It makes a big jack but it seems logical to me...

Or the 1570-1+A1 relating to lift tables (which brings me closer to car decks in garages).

It is a question of remanufacturing a new device, based on the architecture of the old one (no notion of bad aging here).

I would like to find out the standards that apply to know which coefficients to apply and how, and how to justify the calculations.

Thank you

1 Like

The easiest way is to carry out a pre-study and verification service with the organization that will check the equipment (APAVE, SOCOTEC, etc.) and to send a specification asking for the points to be checked according to which standards...

This will certainly avoid big surprises at the verification (insufficient coef...)

For your information, for a Euro ferry tipping elevator for example, a static and dynamic load test is required, and a CMU plate (yellow and written in black) must be affixed to the equipment in addition to the CE plate.

Here is an example validated by a control body:

But the main thing is to start with the right standard by asking for a complete service you make sure that the organization that advises you is the same one that validates and impossible to get the wrong standard this way, if your specifications are clear.

1 Like

Precisely, the return of the apave (decree of 2004 concerning a return to operation of a piece of equipment) does not seem to me to match our expectations. I'm going to contact them again.

Thank you

For my personal experience with Apave, it is often complicated.

With Socotec, things generally go much better and exchanges are therefore facilitated.

For the record, I have no part in either of them!

3 Likes