Hello

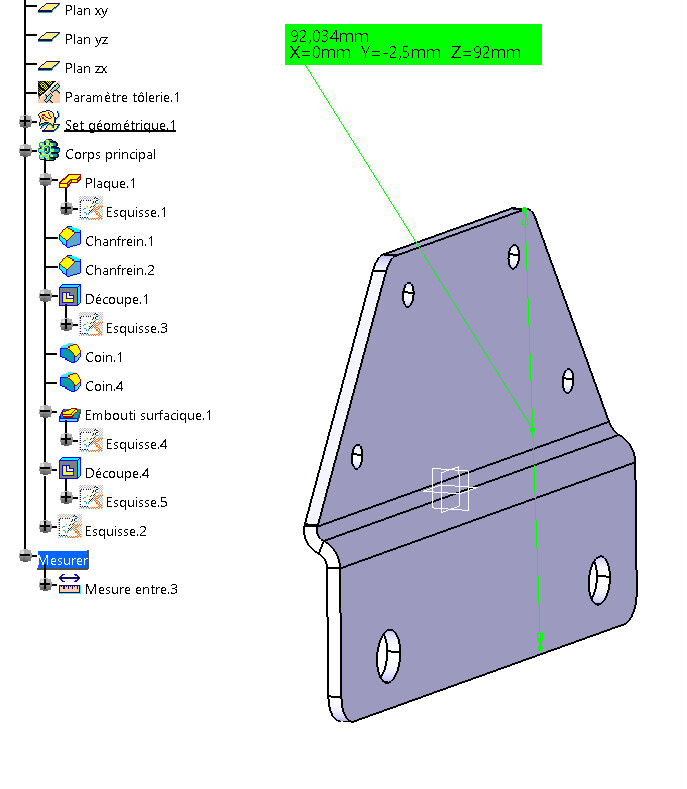

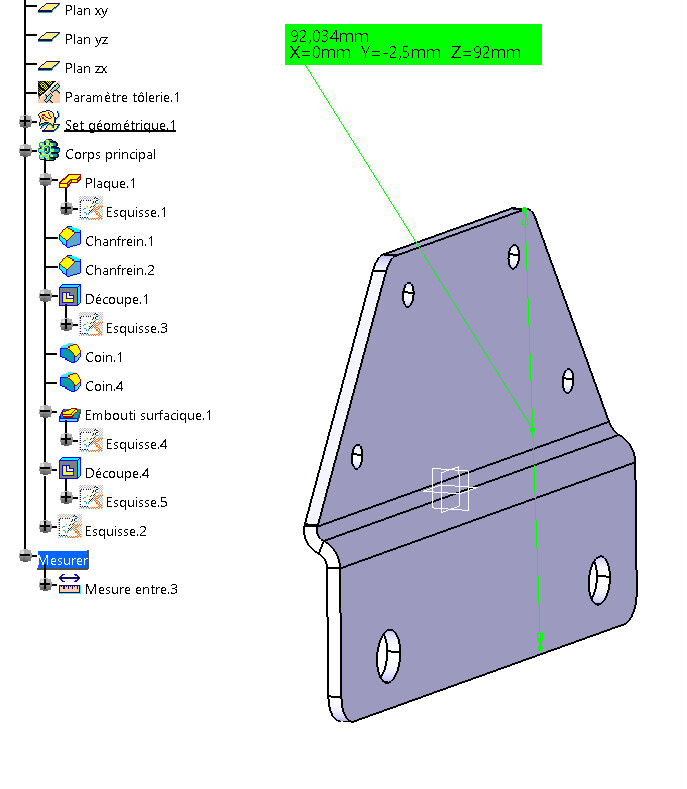

I have a problem with the unfolded ones that don't take into account the radii of my stamping

What am I doing that is " not right "?

Thank you d av.

Hello

I have a problem with the unfolded ones that don't take into account the radii of my stamping

What am I doing that is " not right "?

Thank you d av.

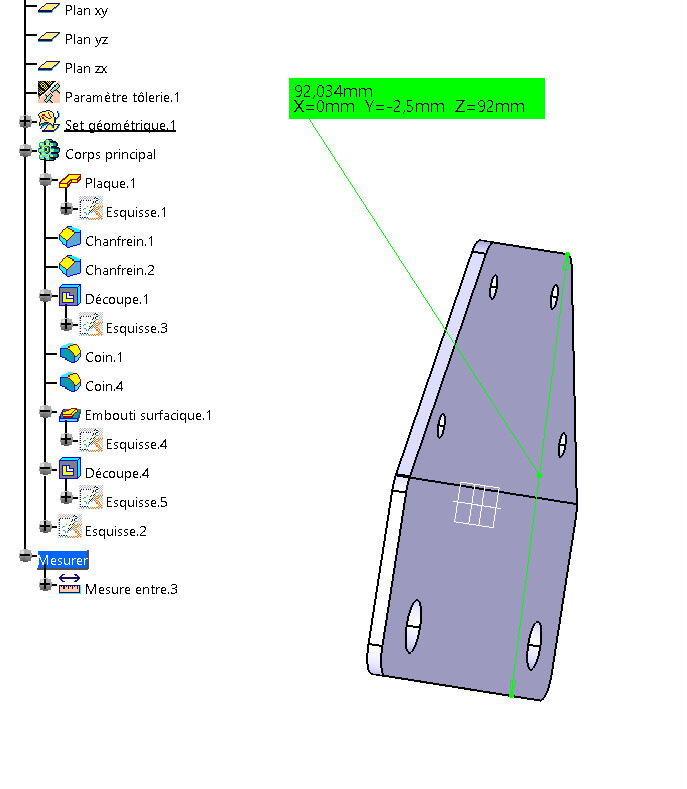

image of unfolded

Thank you

Hello.

For me, your problem comes from the fact that you don't work in " Sheet metal " in the sense that you don't have any wrinkles.

The stamping function deforms your part (it stretches the material)

If you are sure that your piece is made by folding, you should instead make 2 folds on top of each other or use the " Off-hook " function.

Ok thank you.

Is there a function that allows me to control the 5.5 mm offset between the faces of my part.

If I make 2 folds, (with angles at 45°) at no time do I know the offset of the 2 parallel surfaces.

It becomes a hassle, to find how many lg it takes at the 1st ply to obtain (at the 2nd ply) the 5.5 mm offset

What I understand from your explanations: I have to create an " extrusion " with a sketch that contains the offset of 5.5, right?

As a result, I find it " a bit rubbish ": I liked the fact that this offset is a " parameter " defined by a " stamping "

In this case, you must use the " Off-hook " function of the " sheet metal work " module

ok for that, thank you

otherwise I'm on Catia and they're not quite the same icons

So I have to redo all my sheet metal parts, argghh!

Hi coin37coin,

Be careful, it's Catia, not SolidWorks, but it's the same company... HIHIHHI

Hello

That said, I doubt that it will be feasible with the press brake. What is the thickness of the sheet metal?

Hello, I'm brunet_f's colleague and answer for him (punished for 19h by the forum...)

This is a 3mm sheet, deform punch die.

Thank you

Stamping OK