Hi all

I am having a problem using the sheet metal function.

Indeed, when I enter my thickness as well as my loss at the fold (reference of the losses at the fold given by a colleague who has been working in the company longer than me), I cannot develop my piece, except by using the K factor but I can't find anywhere how to determine the K factor and therefore, The laser parts that come out of it are not correct.

Is there any software or simple calculation to determine the K factor?

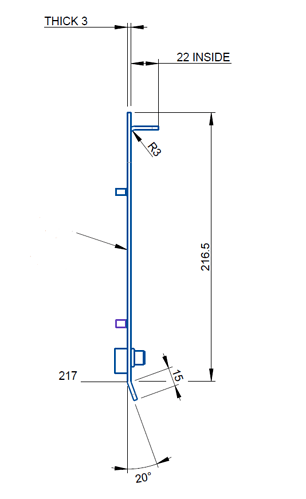

Here is an example of one of the parts that does not want to go into development, with a crease loss of 6mm

Hello

The loss at the bend depends on each press brake, their clearance and the tools used, as well as the direction of rolling of the sheet, in my box I did test tubes to get out a K factor, look on the machine, there must be an abacus plate thicknesses / tools (size of the Vs) it will give a starting point.

6 Likes

Hello

recurring problem.

We also tested and determined the K-factor for all thicknesses, material, vee used, and then filled in the SW tables.

It's long but it allows you to have good quality laser cuts (unfolded).

1 Like

Thank you for your answers, I will try to find this data within my team.

@Le_Bidule , I saw these famous tables when searching online, but I couldn't find them on SW, could you tell me more about that?

What I say to myself every time the purchasing department asks me for a unfolded part to have the part made by a new supplier... and what they strive not to understand. It's tiring in the long run!!

Otherwise, for @Neko_3D, it is unfortunately something empirical of which only you have the knowledge. Good luck finding the info

Hello

Here is a table in which I have calculated the neutral fiber coeffs (K factor) with respect to the thickness . I based myself on the loss at the bend (Delta L) and bend radius given by the charts of Amada folding machines.

Coeffs pliage.xls (29 KB)

I have been using it regularly for several years.

However, the vee used during bending must be the same as the one provided for in the design of the part. Otherwise it influences the radius and it displaces the neutral fiber.

1 Like

Hello and thank you for your answers.

@d.Donval , thank you for your painting, it will already give me a base that I will desecrate over time.

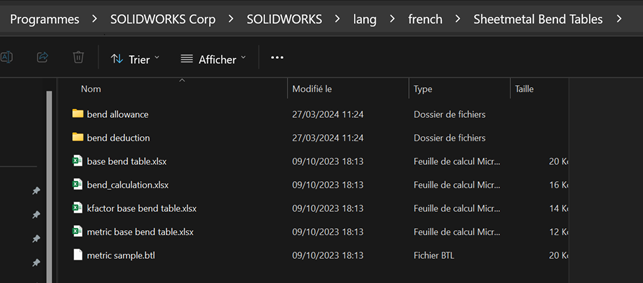

Here is the path for a standard SW cfg

Hello

Small precision, these values are suitable for steels (S235 and/or stainless steel 304-316).

Not for other metals (aluminum, copper, etc...)

Different elongation.

2 Likes

Indeed, when I go through a supplier, on the plan of the part I put the press, its capable square and the folding dimensions but always with a box " developed for information purposes", it is the dimensions of the finished part that are authentic.

Ahh... these buyers!..

1 Like