Hello

I am in the process of making an assembly with parameterized parts.

Basically, each piece comes in several sizes and in my assembly I create several visuals from these variations of parts.

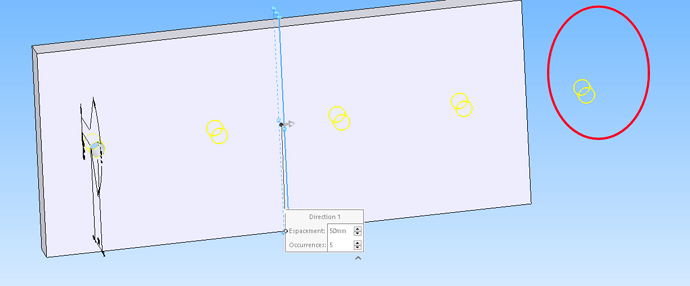

Everything was going well until I inserted an element that repeats based on the repetition of holes it is inserted into. While doing so I told myself if my set calls for a part with a repetition of 3 holes, the model will display 3 screws (it's threaded rods), if the model calls the part with 8 holes, I would have 8 screws etc ...

Well no, the number of screws always remains the same, so I have screws that come out of the model and worse than that, the first screw is not even the first hole.

I probably missed something...

Do you have an idea? I admit that I'm going around in circles a bit.

I'm on solidworks 2020 Premium SP3.0

It works fine like this if 3 holes=3screws, if 8 holes=8 screws.

Unless your continuous drilling repetition in the vacuum and then the screws also go into the void. (see image in red hole in vacuum = screw in vacuum)

If you have put equations in your part the number of holes can follow according to your part without having drilling outside the part and then the number of screws will be correct. (except bug, but under SW2020 no problems)

Hello, Thank you for your help.

I don't have any holes in the void, because the number of repetitions is part of the parameters that I manage manually, I checked this point anyway.

On the other hand I didn't assemble the screw on the hole that served as a repeater, because strangely the piloted repeat function is created, but no screws are added ...

It is better to put the screw on the 1st hole which is then used for the repeating effectively.

What repetition do you use? Several points in the drilling anointing or a repetition of drilling or material removal.

If you can attach a copy of your tree structure or the document if not confidential, it can help.

So I just reassembled my screws, on the function serving as a repeat and there it works, nevertheless on one model, I have 3 more screws, while no worries on the others.

Take a good look in your pilot function if you don't have any problems with this configuration. Apart from bad handling, there is no problem.

I reassembled the repeat for which I had 3 screws in a vacuum, and now everything works, except the default model, but I'm going to remove it.

the difference compared to the beginning and that instead of selecting the repeat hole, I selected the function in the tree, and obviously this solution works better, even if there is still a small bug on the "Default" model.

1 Like

Hello;

In this case, it also often happens that we forget to "Rebuild" the assembly when moving from one configuration to another...

Note: personally, I find that Solidworks 2022 often loses its footing with driven repetitions, especially when selecting the origin point...

Kind regards.

1 Like