To obraźliwe... Brak sztucznej inteligencji dla @m_blt ... to sztuczna inteligencja powinna używać @m_blt makr, aby być skutecznym!

Witam

Przepraszam @m_blt , jeśli zabrzmiałem obraźliwie. Będąc początkującym w VBA i nie mając powołania, aby uczynić z tego swój zawód, sztuczna inteligencja (i samouczki wideo) nadal bardzo pomaga mi zrozumieć różne funkcje używane w makrach i robić rzeczy samodzielnie. Wielkie podziękowania @m_blt za wszystkie udostępniane kody i czas, który na nich spędzasz.

Witam @john_john możesz się zrelaksować, nikt tak naprawdę nie wierzył, że chcesz być uwłaczający, moja uwaga nie była brana za dobrą monetę ![]()

Bah! @m_blt jest jednym z naszych nie-sztucznych użytkowników od co najmniej 11 stycznia 2000 roku. (wyprzedzając swoje czasy).

Dziękuję za te komplementy, rumieniec spływa mi po policzkach...

Pomijając @Maclane : nie musisz mnie postarzać bardziej niż powinienem, moja rejestracja datuje się od 2020 ![]() roku.

roku.

Podejrzewanie mnie o konsultowanie się ze sztuczną inteligencją nie jest obraźliwe, kwestionowałem już ChatGPT lub Le Chat, głównie jako narzędzia wyszukiwania w funkcjach oprogramowania.

Typowy przykład tutaj: " Jaka funkcja API oprogramowania generuje śmigło?"

Odpowiedź ChatGPT:

La fonction CreateHelix ou la méthode CreateHelixFeature de l’objet IModeler

Wszystko to jest czystym wymysłem, żadna z tych funkcji nie istnieje.

Struktura HelixFeatureData , o której wspomniał w dalszej części swojej odpowiedzi, jest rzeczywistością.

Przykład, który pojawia się dalej, wydaje się bardziej atrakcyjny z poprawną InsertHelix()funkcją, ale której parametry są nieuporządkowane i dla niektórych niepoprawne.

Ze swojej strony Le Chat proponuje utworzenie helisy, czyli krzywej zasadniczo 3D, w szkicu 2D. Bez komentarza...

Następnie zapoznaj się z dokumentacją API SolidWorks, aby uzyskać więcej informacji!

Ogólnie rzecz biorąc, dużo czasu poświęconego na losowy wynik. Nawet jeśli pozostaję przekonany, że to tylko kwestia czasu, zanim sztuczna inteligencja stanie się skuteczna w tej konkretnej dziedzinie.

Inne źródła inspiracji, bardziej skuteczne:

- Interfejsy API oprogramowania, w tym przykłady, a także interfejsy API stosu kodu.

- makra generowane przez samo oprogramowanie, chociaż nadużywanie typu Object dla zmiennych czasami wymaga żmudnych poszukiwań w celu znalezienia ich dokładnych typów i członków.

I kilka lat praktyki, nawet jeśli w innym kontekście niż w przypadku API oprogramowania i VBA...

![]()

![]()

![]() Przepraszam za kolejne 20 lat!!

Przepraszam za kolejne 20 lat!! ![]()

![]()

![]()

Ale czego chcesz: " Talent nie czeka na liczbę lat".

Zgadzam się z tobą co do korzystania z AI Vs pomocy API SW + CodeStack ... O ile sztuczna inteligencja nie jest (jeszcze) doskonała i jeśli zaczyna mieć halucynacje, na przykład tworząc nieistniejące funkcje w interfejsach API, jest to zmarnowany wysiłek. Ale to tylko kwestia czasu.

Ale moim zdaniem nauka nie powinna odbywać się za pomocą sztucznej inteligencji, ale z prawdziwymi ludźmi, którzy mają prawdziwe rozumowanie i dobrą wiedzę... lub w najgorszym przypadku za pośrednictwem " poważnych " stron

…

Z drugiej strony używam sztucznej inteligencji do komentowania moich kodów... tam AI nie jest takie złe, a przede wszystkim popełnia znacznie mniej błędów ortograficznych niż ja... ![]()

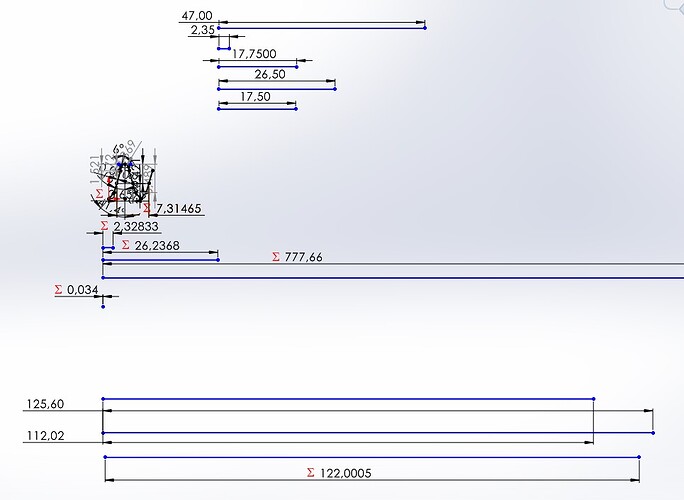

Witam, szkoda, że nie możesz otworzyć plików. W pliku .part mam szkic ze wszystkimi parametrami do zdefiniowania profilu zęba.

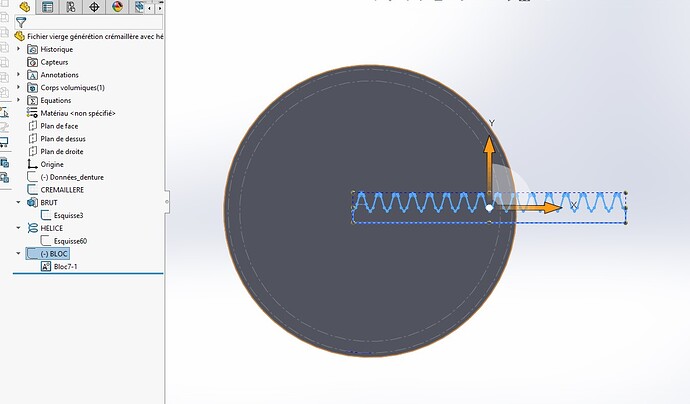

Następnie mam szkic, aby pobrać profil zęba i stworzyć powtórzenie (bazę bloku utworzoną później).

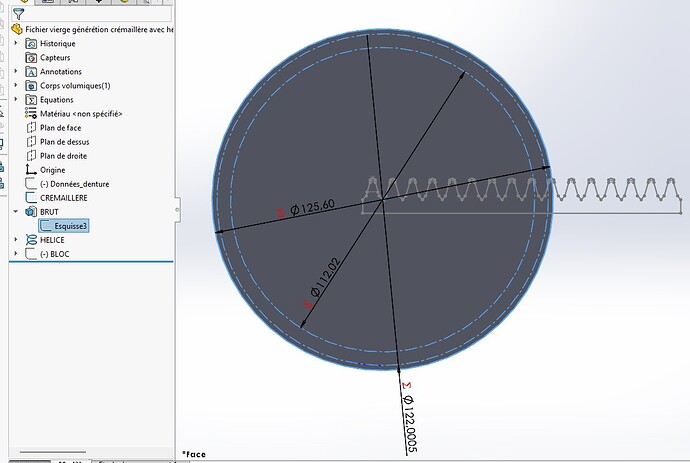

Następnie tworzę surowy z Ø stopą, Ø głową i Ø prymitywem.

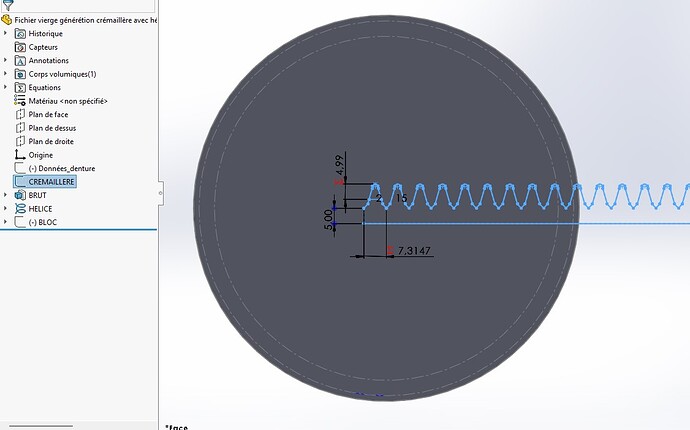

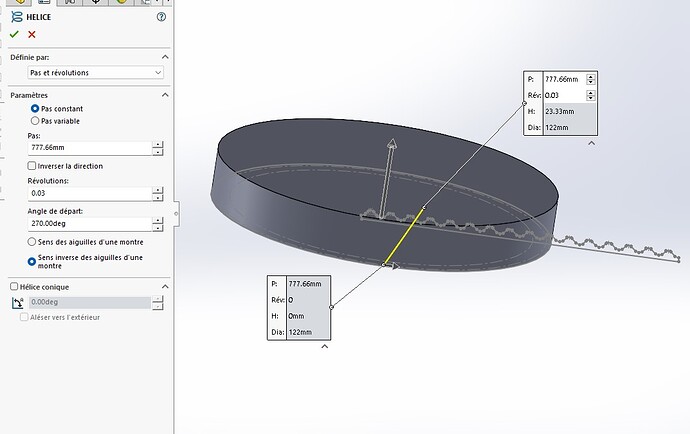

Następnie tworzę śmigło z parametrami, które są w porządku dla mojego przypadku (obliczam je na moim 1. szkicu Données_denture ale nie mogę ich zmusić do użycia ich w parametryzacji śmigła, pola danych akceptują tylko wartości liczbowe). Okrąg bazowy helisy to pierwotna Ø, która jest przekształcana ze szkicu zgrubnego.

Na koniec tworzę szkic BLOKOWY, w którym biorę stojak i przekształcam go w blok. Robię to, aby nie " zepsuć " mojego szkicu parapetówki i móc wrócić bez konieczności odbudowywania wszystkiego.

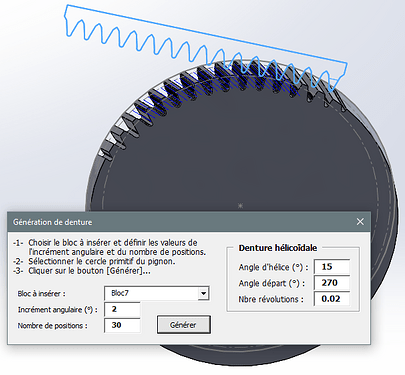

Po uruchomieniu makra

Przekładnia zębata walcowa generacji.swp (77.5 KB)

Cięcia po pochyleniu są zawsze wykonywane zgodnie z tą samą spiralą.

Próbowałem zrozumieć, jak to zrobiłeś, aby powtórzyć śmigła, aby zintegrować je z makro, ale suszę... Dodatkowo uważam, że w moim przypadku muszę odzyskać istniejące śmigło, aby skopiować parametry dla powtórzeń i tam suszę jeszcze bardziej.

Witam

Jeśli twój profil zęba jest szkicem ukrytym pod wielkim stosem wymiarów, nie wydaje mi się, aby był to prawidłowy (lub przynajmniej istotny) profil twojego śmigła.

Witaj @john_john ,

Nie mam pod ręką mojego zwykłego komputera, a ten, który mam, jest ograniczony do SW 2023. Mogę załadować makro, a nie dokument części...

Ale o ile się nie mylę, twoja wersja 2024 ma opcję zapisania w formacie SDLPRT z 2023 lub 2022 roku, wykonując " Zapisz jako ".

Jeśli tak jest, opublikuj swój artykuł w jednej z tych dwóch wersji, przyjrzę się Twojemu makro tak szybko, jak to możliwe...

Stojak na pliki generatora pustego ze śmigłem - AMELIORE SW2023.SLDPRT (195.7 KB)

Stojak do generowania pustych plików ze śmigłem - AMELIORE SW2022.SLDPRT (196.2 KB)

Proszę bardzo ![]()

Miłego weekendu

Witaj @Sylk ,

Nie musisz się martwić: szkic przedstawia profil zęba, powtórzony w N kopiach, aby zdefiniować zębatkę odpowiedzialną za obróbkę koła zębatego.

Helisa to krzywa, po której musi podążać zębatka, aby wygenerować zęby.

Spiralny, jak sama nazwa wskazuje.

Wszystko to przy jednoczesnym zapewnieniu, że pierwotna linia zębatki toczy się bez ślizgania się po pierwotnym okręgu zębnika. Krótko mówiąc, łamigłówka kinematyczna, którą można połączyć z łamigłówką Solidworks, połączoną z łamigłówką makr VBA.

Rozwiązanie istnieje...

Cześć @m_blt

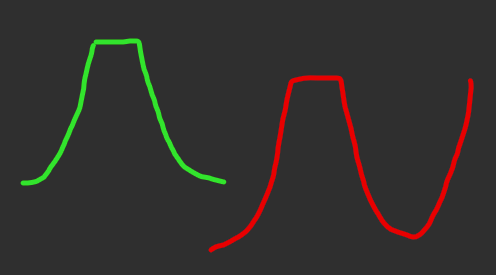

Chciałem powiedzieć, że przy moim ograniczonym poziomie wiedzy profil, nie mówiąc już o powtarzaniu, powinien wyglądać bardziej jak ta zielona linia niż czerwona linia:

Może się mylę.

A może nic nie zrozumiałem z pytania, co jest bardzo prawdopodobne.

Witaj @john_john ,

Nic nowego w załączonym makra, jest ono niemal identyczne z zasadą tego zamieszczonego wcześniej.

Na każdym etapie obliczeń należy umieścić dwa elementy:

- stojak (blok szkicu) oraz

- Śmigło (krzywa), które służy do sterowania usuwaniem zmiecionego materiału.

Zasada działa, ale zastosowanie skanowania sprawia, że jest ona bardziej podatna na odrzucenia obliczeń SW niż wersja z prostymi zębami, która wykorzystuje usuwanie ekstruzji.

Poniżej 2 stopni przyrostu kąta funkcja jest odrzucana przez SW dla niektórych pozycji. Może fakt maleńkich " obszarów obróbki ", którymi ma problemy z zarządzaniem. Czy SW znałoby pojęcie minimalnej ilości żetonów...

Uproszczenie profilu zębów mogłoby to poprawić.

Ostatnia uwaga: obwód okręgu pierwotnego nie jest całkowitą wielokrotnością skoku koła zębatego. Chciane czy nie?

Zębatka walcowa generacji.swp (110.5 KB)

FileGenerationRackPropellerSW2022.SLDPRT (4.0 MB)

Dobry wieczór

Ten przypadek jest nieco szczególny, ponieważ moduł narzędzia (a tym samym jego kąt nacisku) jest zmodyfikowany w celu uzyskania nieco innego profilu. Zmodyfikowany jest również kąt pochylenia linii śrubowej, co nieznacznie zmienia skok śmigła. Poprawione dane znajdują się w Données_denture szkicu i służą do obliczenia oryginalnej średnicy, po której toczy się regał. Myślę, że dlatego niektóre cięcia są " w próżni ", jeśli przyrost kątowy jest mały.

EDIT: to nie bierze się stamtąd, masz rację, są błędy konstrukcyjne.

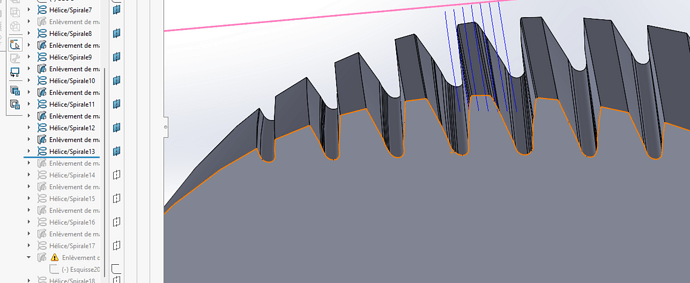

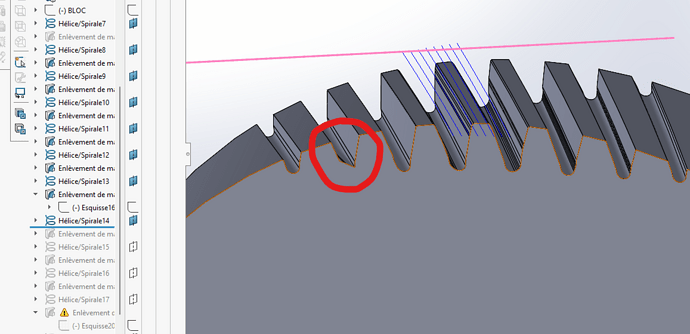

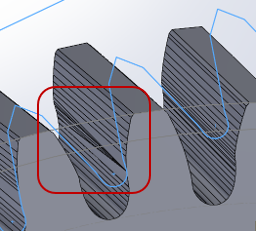

Idę od tego po następnym cięciu helix 13

do tego przy następnym cięciu:

Czy uważasz, że przesunięcie początkowego planu z surowej części mogłoby poprawić sytuację?

Witam @Jonathan_VIALLE ,

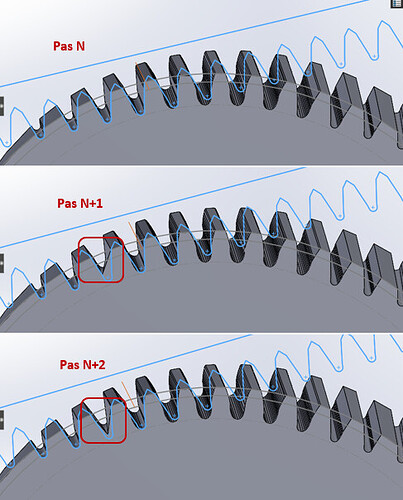

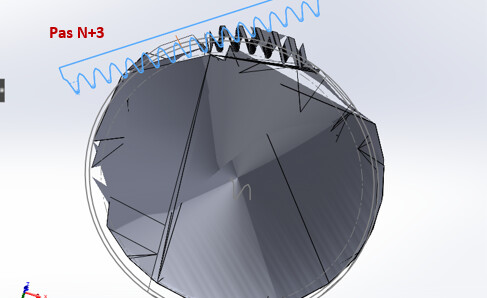

Zauważam to samo zjawisko, osobliwość pojawia się po około piętnastu krokach (N+1), utrzymuje się w następnym kroku, a następnie staje się potworna.

Podejrzewam anomalie cyfrowe wynikające z usuwania drobnego materiału w pewnych obszarach, z którymi SW ma problem z zarządzaniem, a które powodują jego całkowite załamanie.

Przyglądając się bardziej szczegółowo " kolejnej obróbce", możemy zauważyć, że mniej widoczne anomalie występują wcześniej w sekwencji: generatory profilu zęba zbiegają się w tym samym punkcie...

Podejrzenie artefaktu cyfrowego potwierdzone wyborem większego przyrostu kątowego (2,5 stopnia), ponad 40 kroków: koniec z anomalią, wygląd zębów jest poprawny.

Nie sądzę, aby zmiana pierwotnego planu mogła poprawić sytuację.

ok, więc problem trudny do rozwiązania...

Przy dużym przyrostu kątowym powstały trochoid jest zbyt gruby. Moim celem jest precyzyjne zmierzenie początkowej Ø ewolwentu koła.

Wygeneruję tylko szkice i postaram się odzyskać całkowicie wygenerowane " wgłębienie " zęba (w najgorszym przypadku ręcznie). To pozwoli mi na rozwój początkowej Ø. Następnie mogę wykonać zamiatanie zęba i powtórzyć je, aby uzyskać pełne uzębienie.