Hi all

I am in the process of creating parts via an Excel parameterization table and I want to add a tolerance such as h7 to my dimensions for example. But I can't figure out how to write the necessary values...

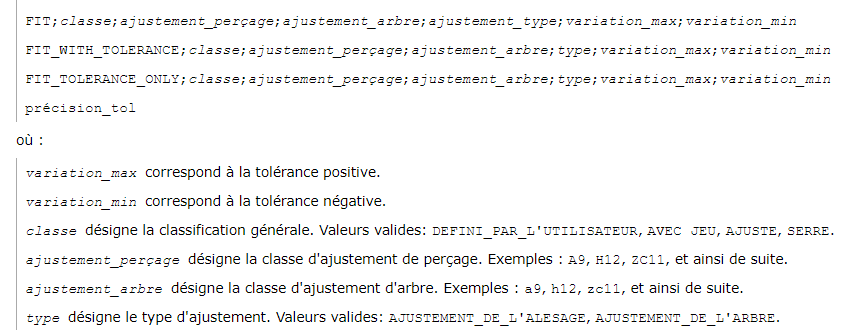

What I am trying to fill is the " FIT_WITH_TOLERANCE ".

In the Solidworks online help we have this information but I don't see how to process it

(inserting a drill and shaft adjustment in the same dimension seems strange to me as well as respecifying the tolerances behind ???)

Anyway I'm a bit lost with very little help on the net so if anyone has a solution I'm interested.

Thank you for your attention

Hello

The easiest way to get how to create/modify things in the part families is to vary your 3D between 2 configurations and see how Solidworks handles this in the Excel part family table behind.

So you create a configuration with a dimension in H12, then on another configuration you pass it in +/-0.5 (or any other type of tolerance), you generate your Excel family and you see the syntax obtained.

From there, you should be able to edit your Excel spreadsheet.

On the other hand, I'm afraid that the values of the ISO tolerances can't be easily modified in the Excel table (Solidworks will probably look for these values in a table in the toolbox or somewhere in installation files when the user chooses his tolerance)

3 Likes

Thank you!

I didn't know that you could create the sheets from 3D, it may help me a lot for the future.

If people ever come across this post later I entered the following formula for a tolerance h6 of a tree Ø5,00

AJUSTEMENT_AVEC_TOLERANCE; DEFINI_PAR_L USER; h6; AJUSTEMENT_DE_L TREE; 0.000000;-0.008000; 3

So if you change the base rating (your ø5->5ø0 for example), in my opinion the tolerance wording (the bold part) " AJUSTEMENT_AVEC_TOLERANCE; DEFINI_PAR_L USER; h6; AJUSTEMENT_DE_L TREE; 0.000000;-0.008000; 3 »

may not update itself

→ to try/validate otherwise you risk having false tolerances on the plan

To validate this, you copy/paste your line into Excel, modify your shaft diameter and see what happens

1 Like

I checked and if it updates automatically by itself