Hello

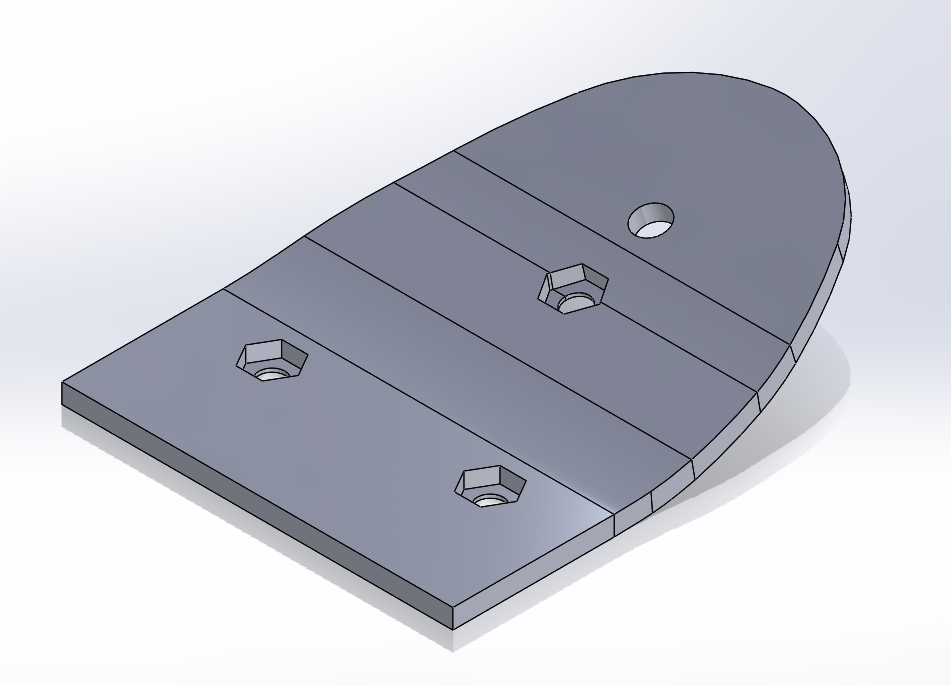

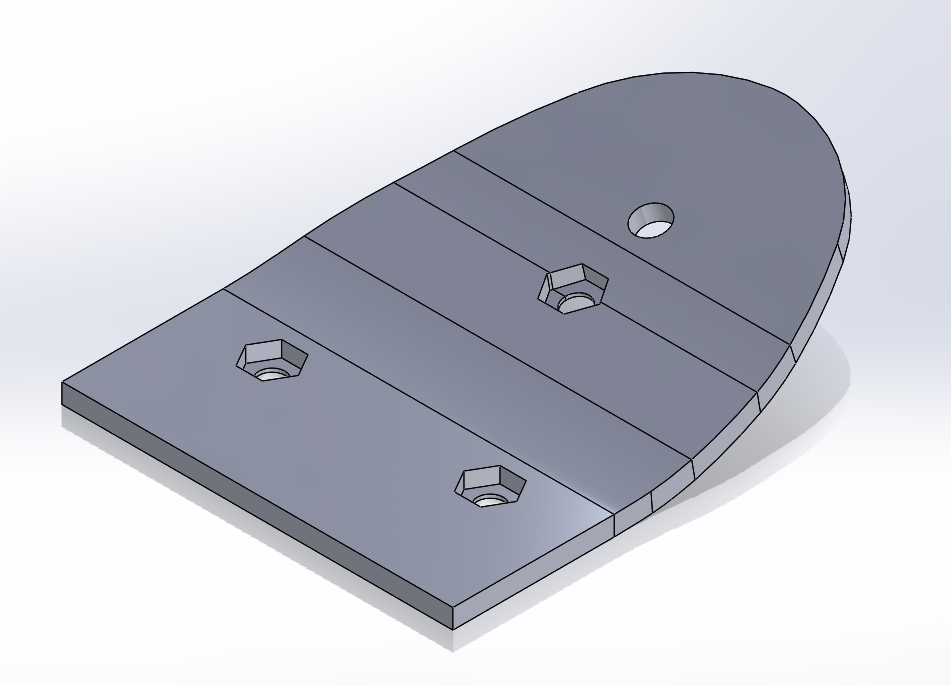

I try to flatten a sheet metal part and when I do the flattening, half of my part " disappears " and I don't understand the origin of the problem.

Could you help me please?

Have a nice day.

Ludovic

Forum_Piece01.SLDPRT (282.5 KB)

Hello

I try to flatten a sheet metal part and when I do the flattening, half of my part " disappears " and I don't understand the origin of the problem.

Could you help me please?

Have a nice day.

Ludovic

Forum_Piece01.SLDPRT (282.5 KB)

Hello;

(… big sigh..) Please specify the Solidworks version used for your part.

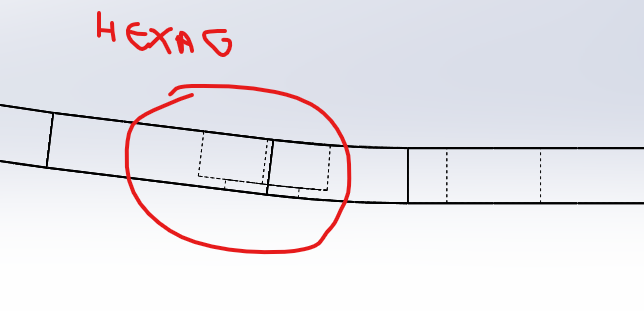

Is your hexagonal material removal carried out before or after your folds?

I imagine that when you cancel your hexagonal removal and drilling functions, your part lays flat properly?

At the time for me, I skipped the version. This is Solidworks Premium 2023 SP1.0.

The hexagonal removal is done before the bending because after I didn't manage to do it.

If I just remove the hexagonal material removal, the part lays flat properly.

The third hexagonal footprint must be normal to what plane?

Amazing is the hexagonal imprint in the middle of a fold.

I don't know how it will behave in folding. (Is it really feasible?)

Edit: what material and folding process?

So in fact the hexagonal footprint is in a pi but with a relatively large radius which means that the footprint is " almost " not bent.

The idea then is to insert a nut in force, like the other 3.

The part will be made of plastic at first and probably aluminum at a later stage.

Ideally on the top plane. I'd like to design the whole piece flat for the arched one afterwards. If it's not feasible I'll make the various cuts once the piece is bent but I think it's going to be much more complex.

In my first idea, I design the part flat, I do my first tests in 3D printing by printing the part always flat and I heat the part to bend it according to a model I have in aluminum.

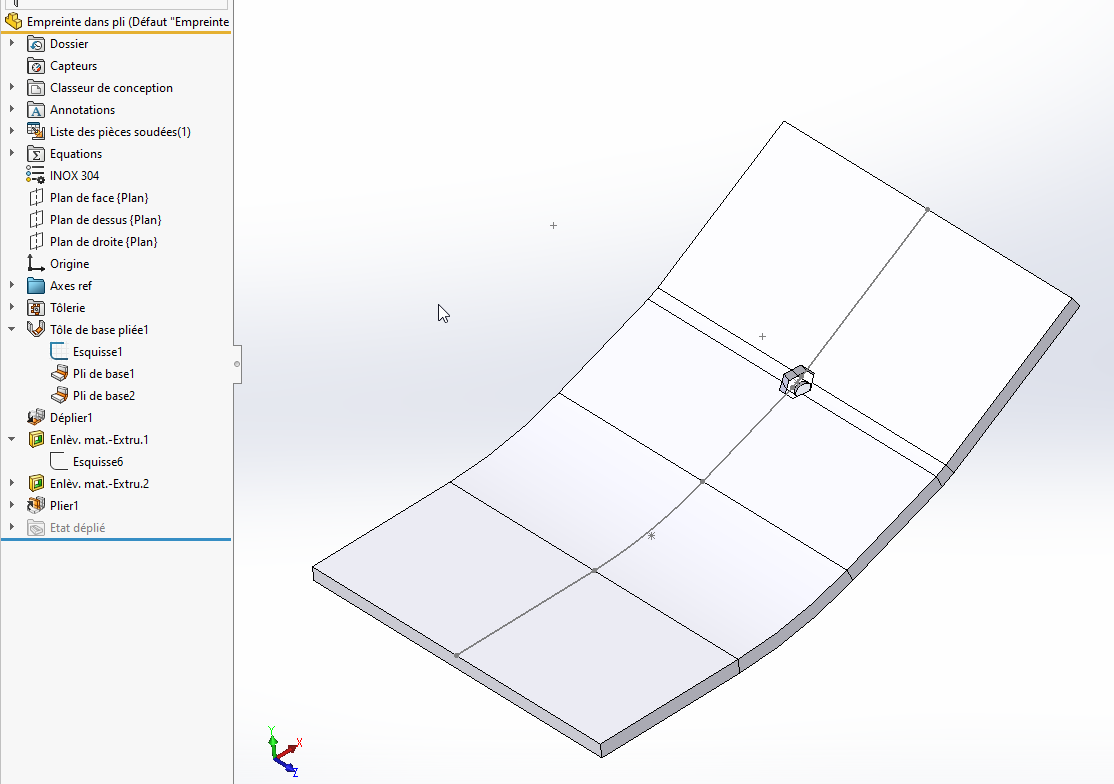

It is because your piercing is not through that it is lost when making it after the fold.

Make your piece folded, then unfold your piece with the Unfold, Material Removal with Impression + Drill function and then Fold.

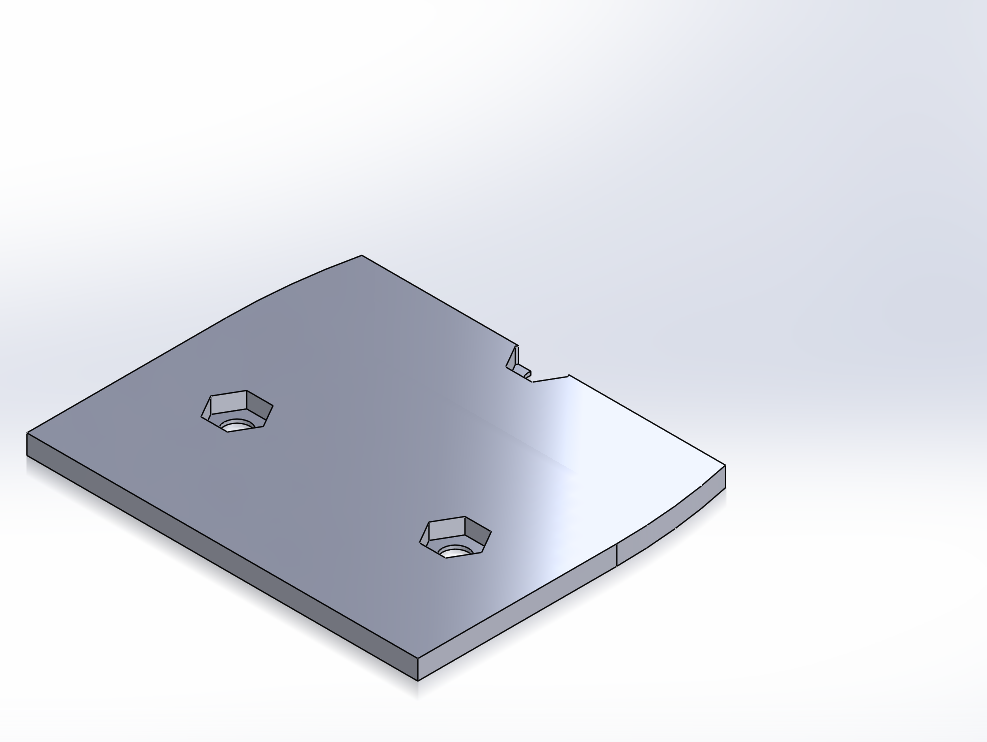

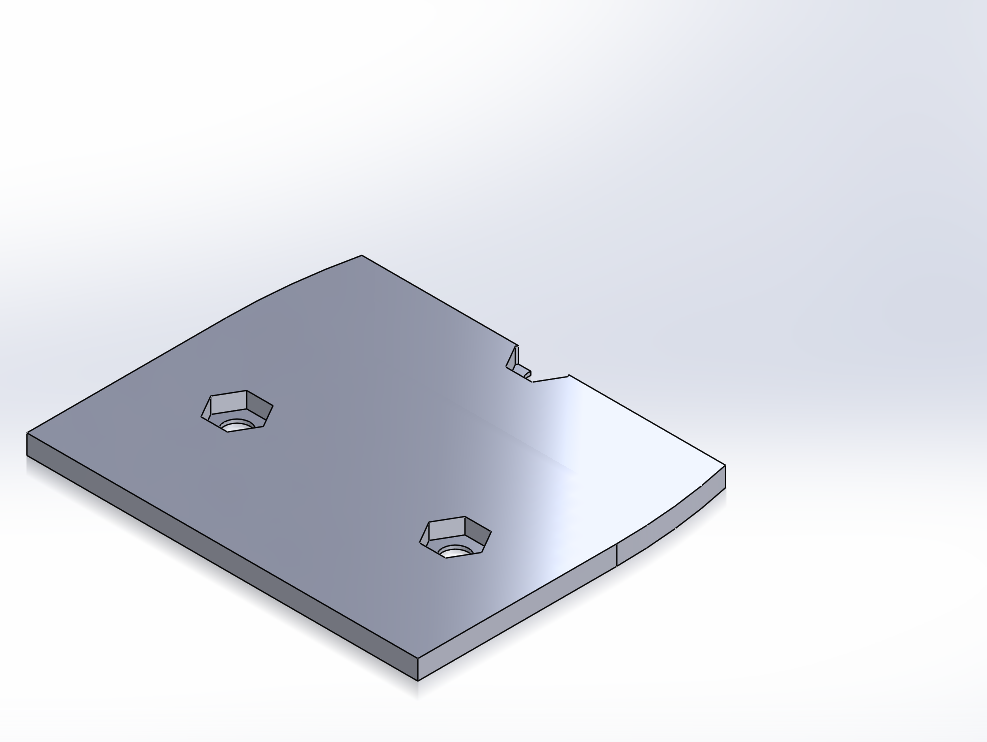

And there the flat function works Sw2023 Sp05.

Example SW2023 file with pifometer ribs!

Imprint in fold. SLDPRT (152.0 KB)

Oh I see, so I have to make my first shape already rounded, right? and not flat as I did on my piece?

Yes, that's how I made my example attachment above.

Ok I'm trying to do that tonight and I'll get back to you ![]()

Thank you very much for your help, this forum is really great!!

Hello

just a little subsidiary question that has nothing to do with the method of building a room with SW.

How are you going to create the hexagonal footprint?

Hello Le_Bidule, In fact the first prototypes will be made in plastic 3D printing. The real models will probably be stamped on flat plates and then a second thinner plate will come from behind to be stitch welded on top. (the whole process is not yet fully defined)

Good evening

So I completely redid the piece starting from a first curved sketch as the expected final result that I then flattened to cut and then fold.

The only place where it gets stuck is for the 2mm x 45° chamfers that I have on some holes behind, I think that the edge of the radius of curvature interferes with the chamfer because as soon as I position the fold BEFORE the chamfers it goes well. And if I delete them, it folds nicely too.

I should try to modify the size in a pinch but I need 2mm x 45°

Hello

The little trick I found to overcome this problem is rather simple:

Hello

oh it's a good idea I'll try to do that ![]()

Thanks for the idea!!

Have a good day too.