Hello, I need your help.

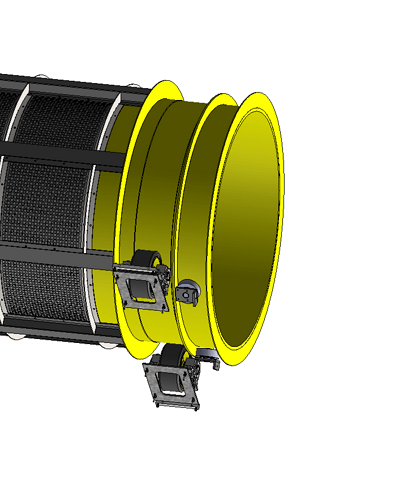

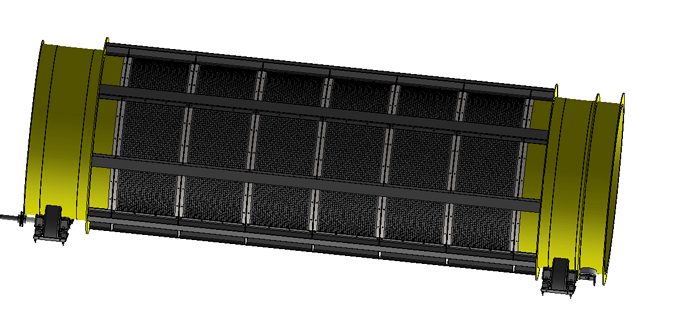

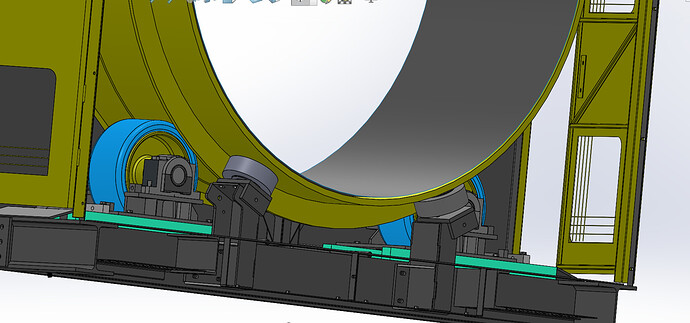

I have a 16 ton tube for a Ø2500mm inclined at 3° with a rotation of 50rpm.

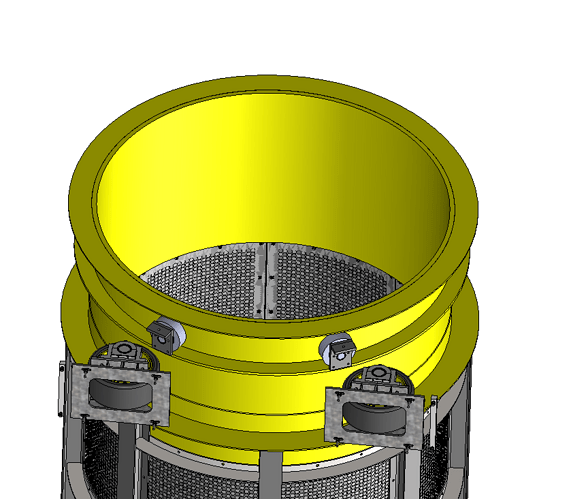

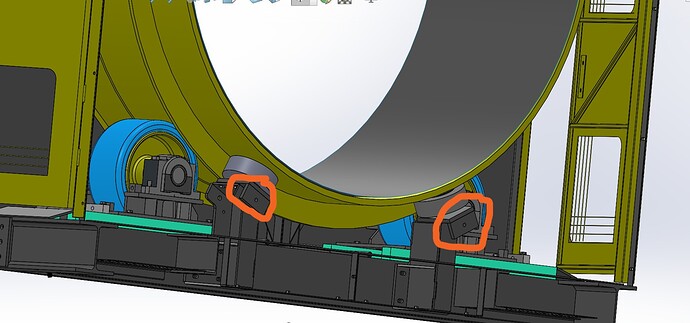

I have to place a retaining roller at the end of the tube to block its translation due to its movement and the force of gravity

I have 2 questions.

1= what is the force at the end of the tube for a roller in the center.

2= what is the force at the end of the tube for 2 rollers spaced 50° apart.

Thank you for your help

How is it rotated driven? Motorized rollers such as a turner?

The tube is placed on 4 wheels, one of which is motorized.

Hello;

Weight (P): P = m * g = 16000 kg * 9.81 m/s² = 156960 N

The component of the weight parallel to the inclined plane: F = P * sin(3°) = 156960 N * 0.0523 = 8209 N

So for a single roller placed in the center of the tube, its holding force is equal to the component of the weight parallel to the inclined plane:

Force for a Pebble = = 8209 N

For two rollers spaced 50° apart, the force will be distributed between the two points of contact. We can use the formula for the resultant forces to calculate the force on each roller:

F_retenue_2 = F / (2 * cos(25°))

F_retenue_2 = 8209 / (2 * 0.9063) = 4528 N per roller

The total holding force will therefore be 4528 N * 2 = 9056 N, slightly higher than the configuration with a single roller due to the distribution of forces.

=> I would add the need to add a safety factor on these rollers to compensate for the centrifugal forces generated by the rotation of the tube...

Without knowing the materials involved, it is not easy to calculate the friction forces.

Thank you very much.

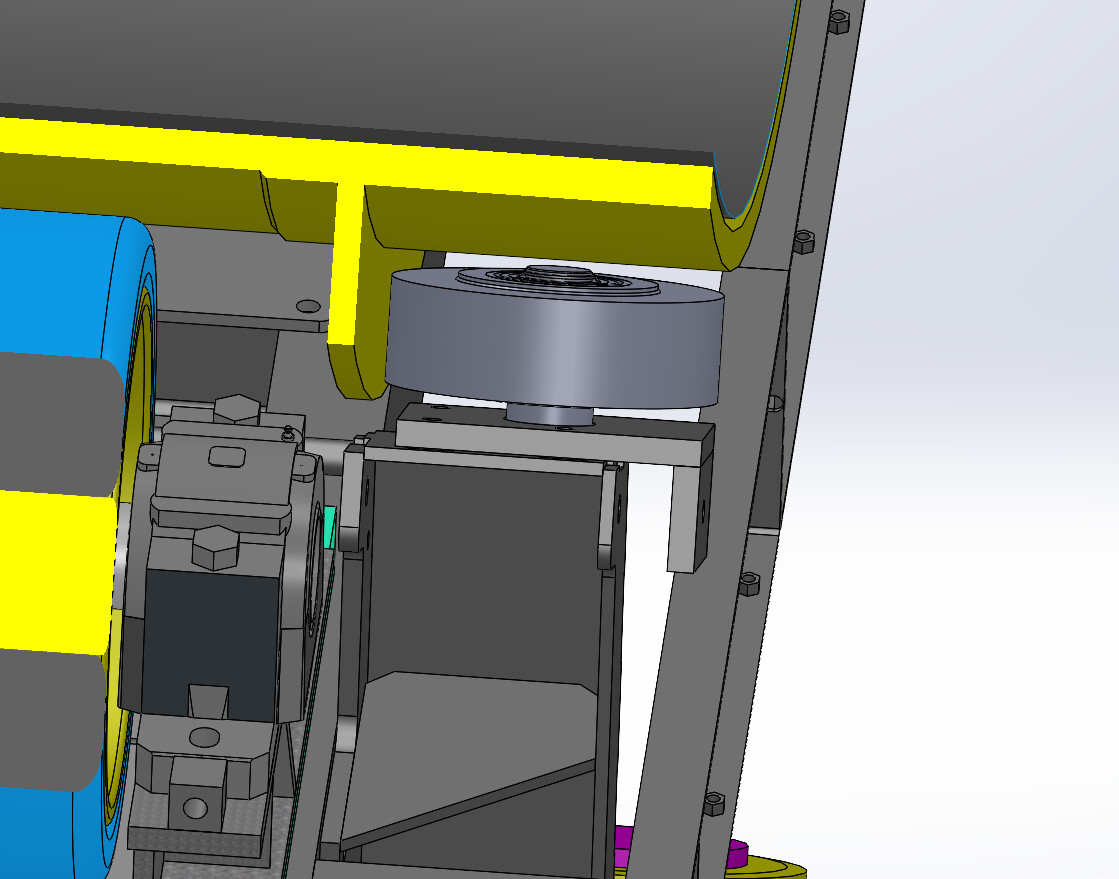

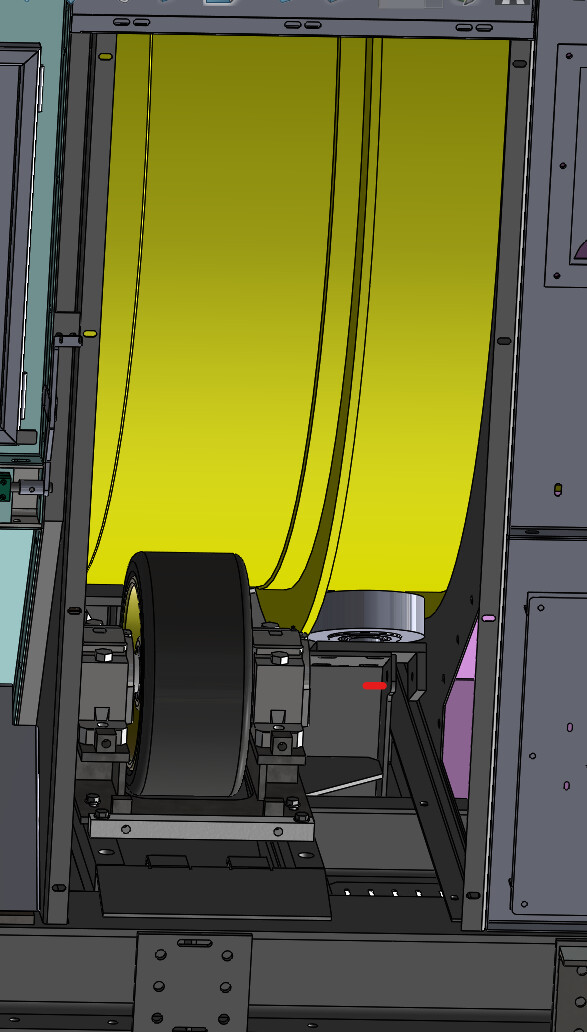

here is the reference of the pebble used

polyamide roller GSPO 252/50K Load 6000 daN

BLICKLE is a good supplier, quality products.

No comment on the model chosen.

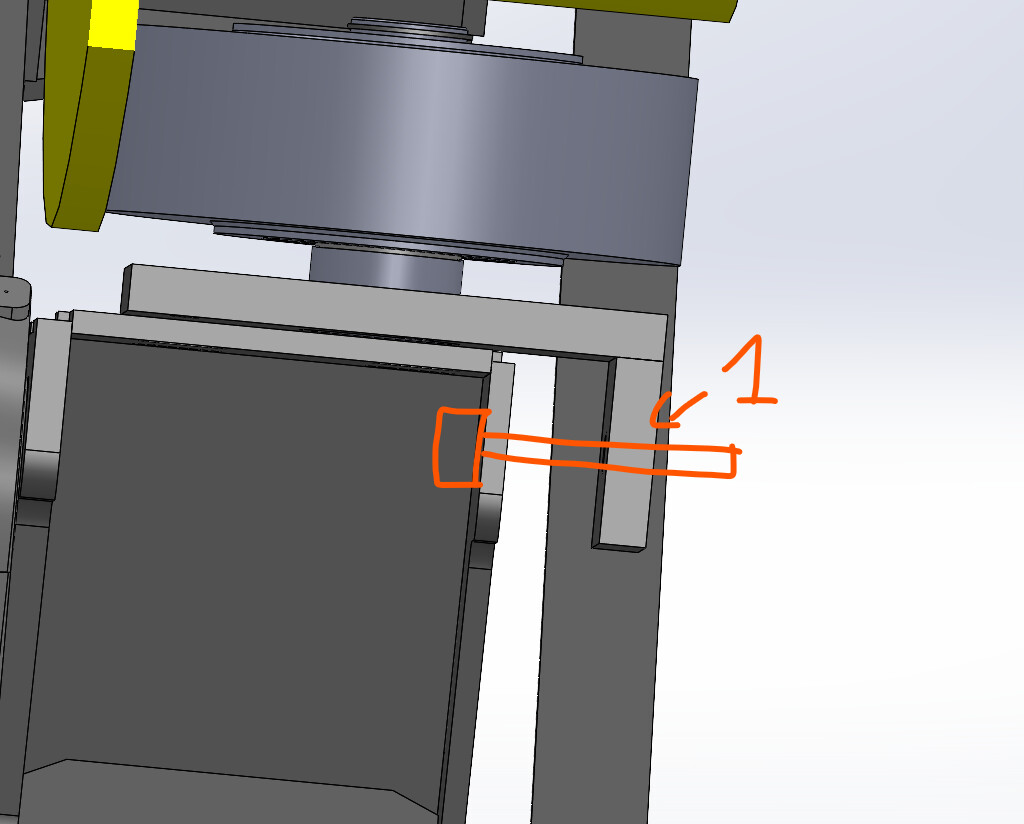

On the other hand, if I may say so, I would have reversed the side of the stop for adjusting the position of the plate rollers, because once adjusted - the thrust forces being still not negligible, perhaps there will also be vibrations (linear speed of 400m/min) - it will be easier to position calibrated shims between the support and the plate. A guarantee of rigidity and stability over time.

Thank you for your proposal.

But it's hard to change the position because I don't have a place.

the roller is fixed from below

the adjustment is done with an M20 screw knowing that in rep1 you are tapped.

pfffff the dark side is showing up ![]()

Thank you to all the speakers for your participation.

May the force be with you.

To determine the force exerted at the end of the tube by gravity and rotation, let's analyze the situation in two configurations:

Data provided:

Tube mass: 16 tons (16,000 kg)

Diameter: Ø2500 mm (R = 1250 mm)

Tilt: 3°

Rotational speed: 50 rpm (ω = 50 × 2π / 60 rad/s ≈ 5.24 rad/s)

Gravity: g = 9.81 m/s²

Case 1: 1 pebble in the center

Case 2: 2 pebbles spaced 50° apart

- Calculation of the force at the end of the tube for 1 roller in the center

Force due to gravity (Fg)

The force of gravity generates a component parallel to the inclined plane that tends to make the tube slide:

F_g = m \cdot g \cdot \sin(3°)

Centrifugal Force (Fc)

The effect of rotation generates a centrifugal force on the center of gravity:

F_c = m \cdot R \cdot \omega^2

All this strength is transmitted to the single roller.

- Calculation of the force for 2 rollers spaced 50° apart

When there are two rollers, the force is distributed between the two, depending on their position and the direction of the forces. Each pebble receives a portion of the resulting force.

I'm going to do the calculations for these forces and give you the precise results.

Results of the calculations:

-

Force due to gravity (Fg): 8.21 kN

-

Centrifugal Force (Fc) : 548.31 kN

-

Total force on a single roller: 548.37 kN

-

Force on each roller (with 2 rollers spaced 50° apart): 302.53 kN per roller

Therefore:

If you use only 1 roller, it will have to support about 548.37 kN.

If you use 2 rollers spaced 50° apart, each will support 302.53 kN.

Hello;

I had a doubt when I read your answer, if only because it doesn't have a " Hello: ", so I went to check on:

and also on:

https://quillbot.com/ai-content-detector

… Please cite your sources when using an A.I... not that they are all bad but we must never forget that they can hallucinate at any time... a bit like humans, by the way.

I think that the fact of pointing out the use of an answer by I. A is above all a question of ethics and respect.

And if I ever get it wrong, please accept my apologies.

@OBI_WAN : I don't have the opportunity to check the calculations mentioned, after all, maybe I'm the one hallucinating... ![]()

Hello @Maclane ,

Indeed, we must be wary of A.I.

I would say that his answers are often relevant, but conditioned by the precision of the question asked, which must be clearly and completely formulated.

In particular, @maurizio's answer contains a confusion, which is not due to ChatGPT: in the case of the " centrifugal force" (Fc = m w² r), the radius r to be taken into account is the distance from the axis of rotation to the center of gravity of the object, and not the radius R of the cylinder. We can think that this distance r is very small if the cylinder is of suitable quality.

In addition, the " centrifugal force" acts radially, and has no projection on the direction of the tube axis.

In my opinion, this centrifugal action is perfectly negligible in the choice of the rollers of the axial support.

To return to the problem initially posed - calculation of the axial force to validate the roller(s) - the fact of using 2 rollers deserves reflection. Let me explain:

No problem for the rotation guidance of the tube, which is carried out by 4 rollers (one of which is motorized), which defines the axis of rotation.

However, there is no guarantee that the rollers used for axial stop will both be in contact with the front face of the tube. It all depends on the quality of the surfaces, machined or raw, perpendicularity of the front face in relation to the cylindrical seats...

Even if the " axial " rollers have an adjustment system that ensures their simultaneous support, there is nothing to say that it will be the same a U-turn later, or for another tube.

Once again, it is the hyperstatic nature of the two-roller assembly that does not allow us to be affirmative as to the equality of the forces they support. It is up to the designer to imagine a solution to guarantee the double support...

Hello @Maclane,

I understand your concern about the origin of the answers and the importance of citing your sources when using an AI. However, I want to make it clear that my answer is the result of my own reasoning and technical knowledge.

If you have any doubts about my calculations or my approach, I would be happy to discuss and justify them point by point. The important thing, in my opinion, is to make sure that the explanations are correct and useful to the community.

Feel free to tell me what you think are problematic points, and we can review them together.

Have a nice day!

Hello

This is exactly what is happening. Machining is carried out on the contact faces with a tolerance of perpendicularity with the axis of rotation but given the size of the tube there is only one roller that is in permanent contact and the second intermittently. We still leave the second one in case the first one breaks.

Hi @OBI_WAN

So wouldn't it be wise to have only one roller but placed on the axis (which would allow a better balance of forces compared to having only 1 roller in contact but not in the axis)?

Especially since with 2 rollers, if ever the supernumerary is mounted too close and it actually comes into contact, you will end up with alternating fatigue on your 2 rollers / supports (so increased risk of breakage in the long term).

@froussel

Yes you're right but placing the roller on the axis becomes inaccessible for maintenance. the choice to place it at 50° and to make it accessible.

Hello @OBI_WAN ,

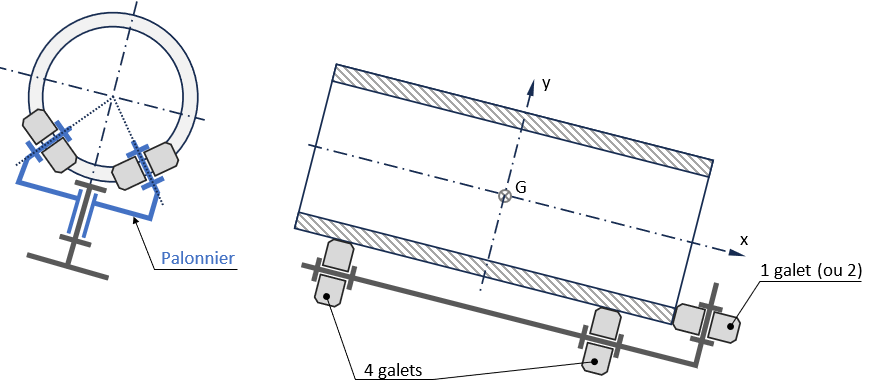

A layout with a rudder bar to connect the two rollers may be the solution:

- theoretically identical distribution of forces on the two rollers (if the rudder pivot is " centered ");

- Accessibility preserved, identical to that with two rollers with fixed axes.

And the pivot connection does not need to be particularly careful, since the amplitude of the movement is insignificant, only due to the geometric defects of the tube.