Hello

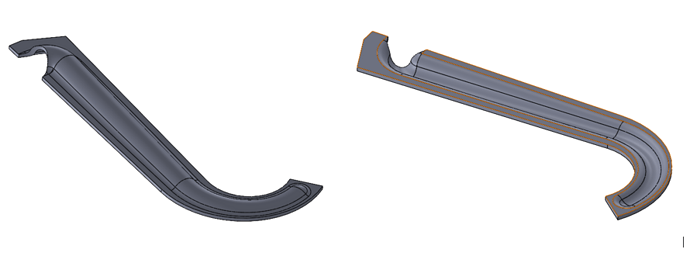

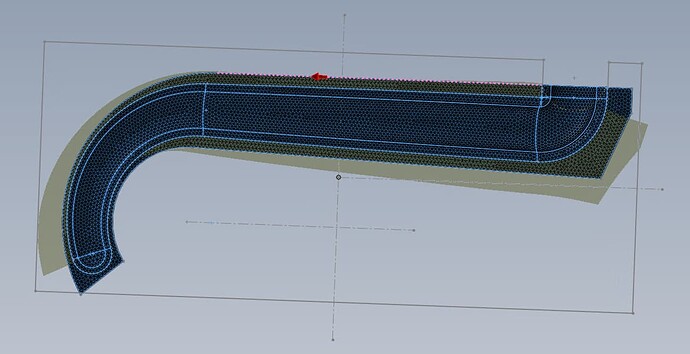

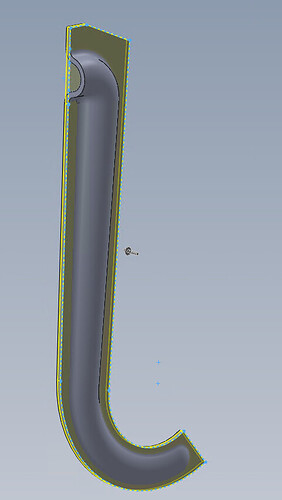

I created a sheet metal on SolidWorks, which I stamped with the ' stamping tool' function. So far so good.

On the other hand, I can't unfold my sheet metal to be able to cut it flat.

Not having too much knowledge in stamping, I don't know if stamping the sheet metal will deform it much.

So, how do you unfold a stamped sheet metal?

Thank you for your answers.

Hello Nico,

Unless I am mistaken, it is not possible to unfold a stamped part.

But I think someone will find a solution.

Good luck, @+.

AR.

Hello,

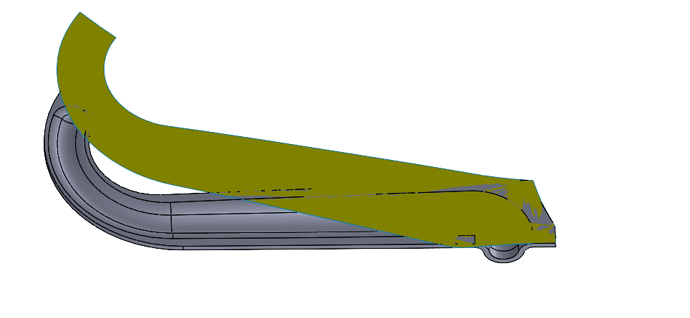

It is possible to carry out flattening by using the surface:

Shift the surface to 0, use the surface flattening feature ( Flattening Surface - 2021 - SOLIDWORKS Help) and then recreate the sheet metal with the thicken function.

I would add to @Silver_Surfer's answer with a lot of uncertainty about the reality of the developed, which depends on the machine and the tools used, so in general on the person who makes the part. (if subcontractor) Internal see with the person who makes the part if necessary to offset the surface has the neutral fiber or not.

I had already tried with the flat surface function, but it shifts everything for me, and I don't know how I can create my punch/die with an offset surface like that.

Either I do it wrong, or what I want to do is not possible, and I will have to recreate a machining rework after stamping

.

Or else it's just the tool that is not suitable for unfolding a stamping in a real way

Is it possible to make the part file available?

@sbadenis is right, there is always uncertainty about the development. It's a palliative, we agree.

Hello

In theory, the unfolded part corresponds to the one before the stamped function, but how to manage the loss of thickness due to stretching is something else.

I don't know if SW generates different thicknesses, from memory the thickness remains constant when in reality it is not.

Yes that's where I ask myself the question, I think that stretching generates an evolutionary thickness, but SolidWorks should not manage this problem

Being a surface function (no thickness); The discrepancy is - in my opinion - normal, logical.

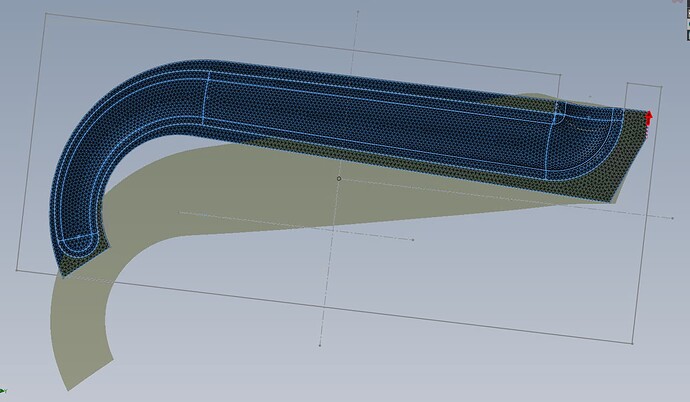

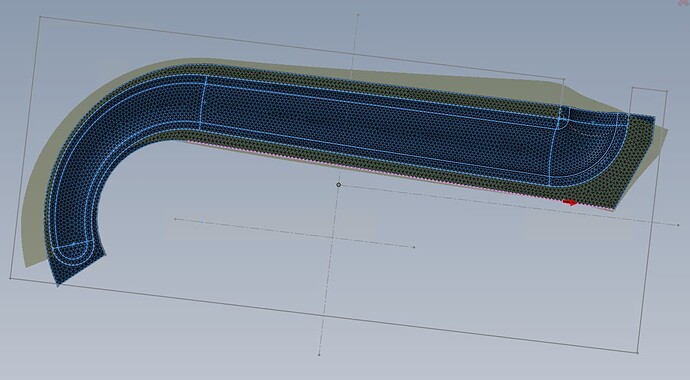

Depending on the edge selected in the flattening feature, the orientation of the flat surface will change:

In this case, rather than going through the flattened surface feature, perhaps recovering the silhouette ![]() with a simple extrusion will yield the desired result:

with a simple extrusion will yield the desired result:

By disabling the stamping function we don't get the same thing?

For me, it will give me the result flat, before stamping my sheet metal

No, not quite, but by tracing differently it is indeed possible.

I am not a sheet metal specialist, but the cutting is not carried out after stamping?

We never do stamping but only bending here.

I wonder if it's like folding, we cut and stamp. And then, the thickness of the sheet will be variable with the stretching.

Or we stamped and then we cut it.

I will find out which case to apply.

In any case, thank you for your help.

There is a different way of stamping, i.e. 1 tool that is stamped with a sheet metal that has already been cut.

either a sheet metal that is stamped and then a 2nd tool / press that comes to cut (it can be the same 2-stage tool)

or in the case of assembly line manufacturing, working in clusters, the sheet of sheet metal is advanced, 1st press 1st form, then one step forward, then 2nd press 2nd form and so on. (in a cluster because the pieces remain attacked each other until the last step.

It's hard to find examples in the field, but here's a nice video.

At the second 32, for example, there is stamping + trimming/cutting at the same time (since it removes the waste)

Basically, you have to choose according to your production objectives and your machines.

Edit: in your case I would add 5/10mm on the outline, which will be chipped at the press at the same time as the stamping.

What makes it not necessary to make an unfold, everything lies in the design of the dies. The excess sheet metal is cut at the end of the operation.

Thank you for this explanatory video.

I'm going to make my die and punch with a larger sheet metal, and I'll cut it all out at the end.

Thank you ![]()

@FUZ3D seems to have given the most relevant answer (in my opinion); @Nico_MPLS_28 don't forget to designate it as such!