Hi all

I need help with methodology.

I am used to working with Inventor which is very easy to use as far as drawings and bills of materials are concerned. We have recently been working with Solidworks 2024 SP5 in our company.

We wanted to experiment with the welded construction module. This one is pretty nice to use... Except for the plans. At least, with our current methodology.

Let me explain:

Our company designs and manufactures electro-hydraulic lift tables. So we are in boilermaking/metallurgy. We have all the resources at home: scrap yard, machine shop, assembly/welding, hydro-electricity. , painting/finishing, packaging/shipping. We have total control of all our raw materials and all our products (including cylinders).

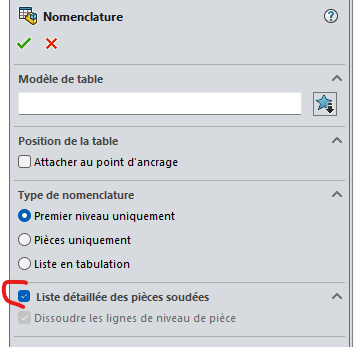

This structure requires us to make detailed plans of our mechanically welded assemblies. For example, I have a first level of " equipped " sub-assembly whose plan contains a bill of materials with ALL the parts of the latter (mechanically welded or not) that we then enter into our ERP.

In this nomenclature, our table consists of information in the following order: Coordinate system / Machining plan number / Quantity / Designation / Length / Width / Material / Manufacturing method / ERP code.

If a part contains machining (milling/drilling), it will have a particular manufacturing method so that the plan can go directly to the right place in the workshop. So it also has a machining plan number, which corresponds to the Drawing Number/Coordinate System (For example, if I have a chassis plan that has the number 01 and my machined part has the coordinate system 12, the machining plan number will be 01/12)

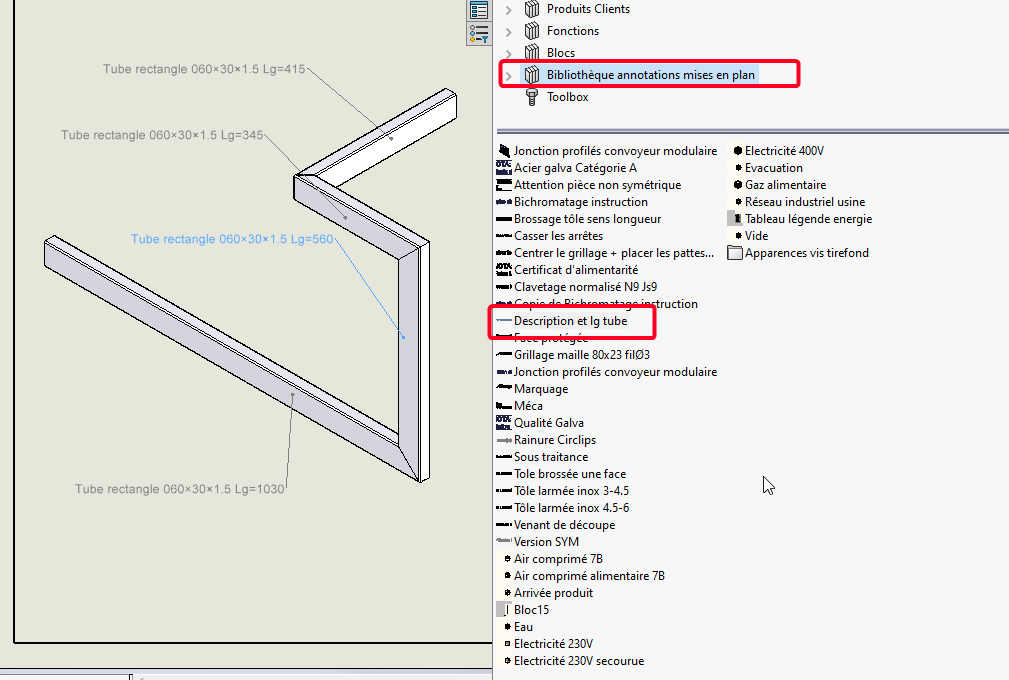

When the manufacturing methods and the machining plan numbers are defined, we make the detail drawings that we call " Flow Plans". Each machined part has its own unique plan with its views and dimensioning. This allows us to correctly sort our plan folder according to the workshop destination.

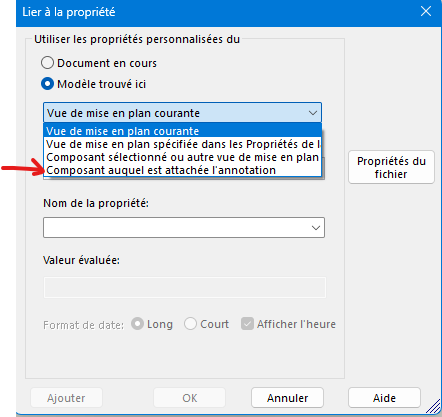

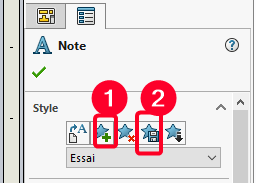

The problem I have is that when I want to do this methodology with welded construction mixed with assembly, I have to fill in the properties of each part. For welded construction, these are the properties of the cutlist. I would have to be able to retrieve these properties in my plan, because I have a specific cartridge that differentiates between a flow plan and a timeline. Today, I have not found any way to be able to recover these body properties from the welded construction. It's a shame, because the welded construction is rather well done and allows you to make welded mechanics very quickly, but suddenly the time saved in 3D is largely wasted in 2D since I have to fill all my cartridge by hand via annotations, piece by piece, sheet by sheet (and when you have large sets, it quickly becomes very, very long).

My question is: Is there a way to recover these properties? Via a macro or a myCAD tool for example? Or maybe a feature I don't know about on Solidworks?

You will find attached an unfinished sample plan.

24-1011-06-FALSE CHÂSSIS.pdf (247.8 KB)

Thank you in advance.